Refining process of grease rich in natural antioxidants

An antioxidant and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problem of easily destroying the original nutrients, and achieve the effect of reducing the risk of degradation, reducing the degree of degradation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An oil refining process rich in natural antioxidants is carried out in the following steps:

[0026] (1) Decolorization process

[0027] Based on the weight of crude corn oil, transfer the crude corn oil into a decolorization tank, add 0.1% of a 10% sodium hydroxide aqueous solution under stirring, and stir for 30 minutes; then add 3.0% of activated carbon and 2.0% of zeolite, and heat up Stir at 60-70°C for 2 hours, control the rotation speed at 500-600rpm / min; heat filter to obtain decolorized oil.

[0028] (2) Dewaxing process

[0029] Transfer the decolorized oil into the dewaxing tank, add 5‰ of diatomaceous earth, control the temperature of the decolorized oil to 35°C for crystallization for 3 hours; then control the cooling time for 4 hours to cool down to 20°C and keep it for 12 hours; continue to cool down to 5°C and keep it for 14 hours ; Filter to obtain dewaxed oil.

[0030] (3) Deodorization process

[0031] Heat the dewaxed oil to 190-195°C. After reac...

Embodiment 2

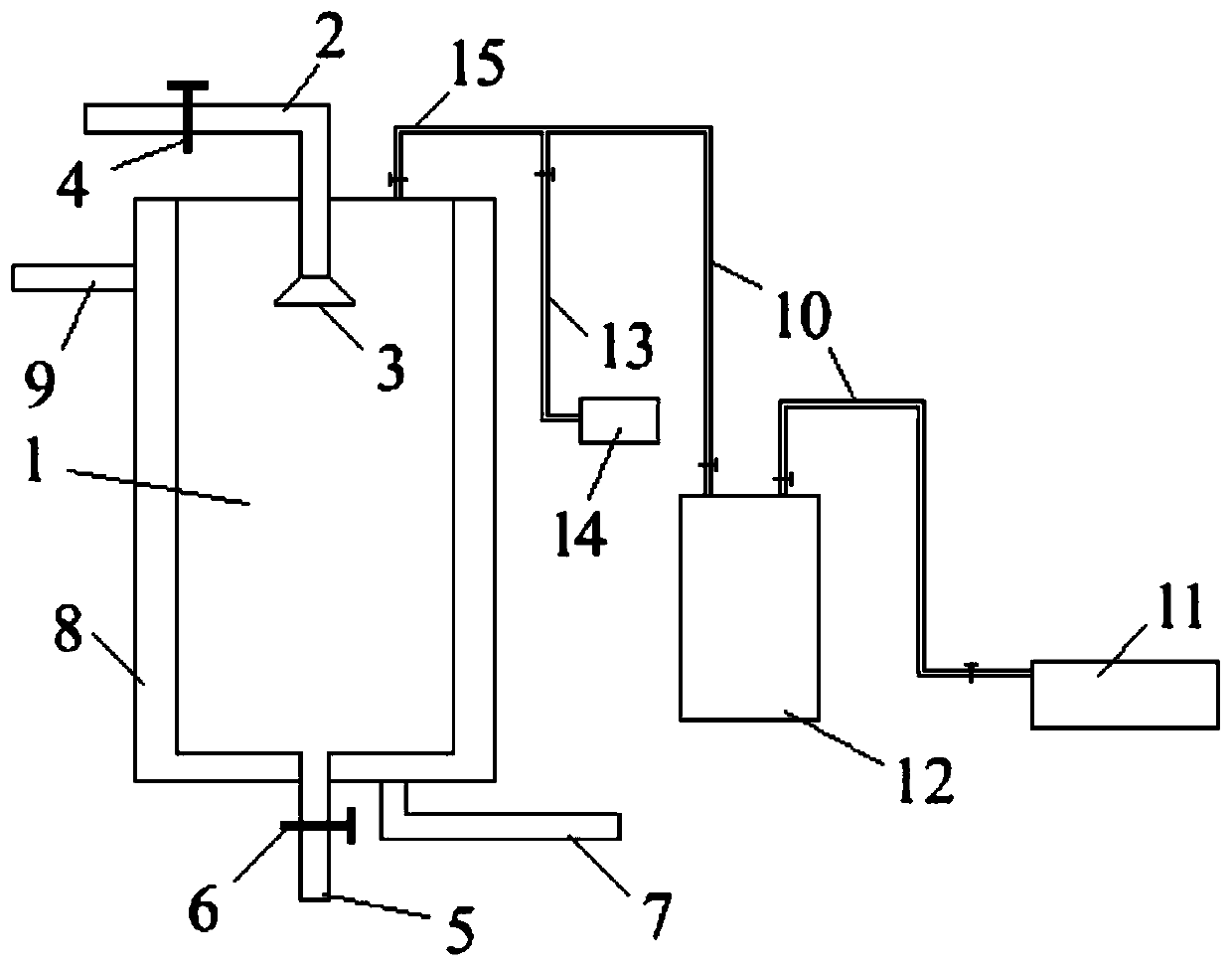

[0033] On the basis of Example 1, the deodorization system includes a deodorization tower 1 , an atomizer 3 , a vacuum pump 11 and a nitrogen generator 12 . Described deodorization tower 1 is provided with interlayer 8, feed pipe 2, discharge pipe 5 and gas pipe 15; Described interlayer 8 is provided with interlayer inlet pipe 7 and interlayer outlet pipe 9; Described feed pipe 2 is provided with inlet Material valve 4; The outlet of described feed pipeline 2 is provided with atomizer 3; Described discharge pipeline 5 is provided with discharge valve 6; Described gas pipeline 15 links to each other with vacuum pipeline 10 and nitrogen pipeline 13; The vacuum pipeline 10 is connected to the vacuum pump 11; a buffer tank 12 is arranged between the vacuum pipeline 10 and the vacuum pump 11; the nitrogen pipeline 13 is connected to the nitrogen generator 14.

Embodiment 3

[0035] An oil refining process rich in natural antioxidants is carried out in the following steps:

[0036] (1) Decolorization process

[0037] Based on the weight of crude corn oil, transfer the crude corn oil into a decolorization tank, add 0.2% of a 10% aqueous sodium hydroxide solution under stirring, and stir for 30 minutes; then add 2.5% of zeolite and 2.5% of clay, and heat up Stir at 60-70°C for 1.5h, control the speed at 500-600rpm / min; heat filter to obtain decolorized oil.

[0038] (2) Dewaxing process

[0039] Transfer the decolorized oil into a dewaxing tank, add 8‰ perlite, control the temperature of the decolorized oil to 30°C for crystallization for 3 hours; then control the cooling time for 3 hours to cool down to 20°C, and keep it for 12 hours; continue to cool down to 5°C, and keep it for 14 hours; Filter to obtain dewaxed oil.

[0040] (3) Deodorization process

[0041] Heat the dewaxed oil to 190-195°C. After reaching the temperature, transfer the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com