Immobilized enzyme, preparation method therefor and application of immobilized enzyme

A technology for immobilizing enzymes and reductases, applied in the directions of immobilized enzymes, biochemical equipment and methods, oxidoreductases, etc., can solve the problem of difficulty in realizing the recycling of sensitive enzyme activities, and achieve the effect of improving mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

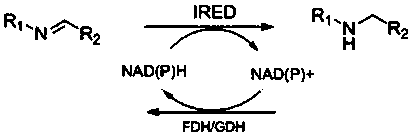

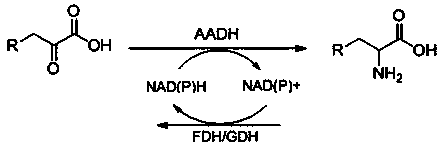

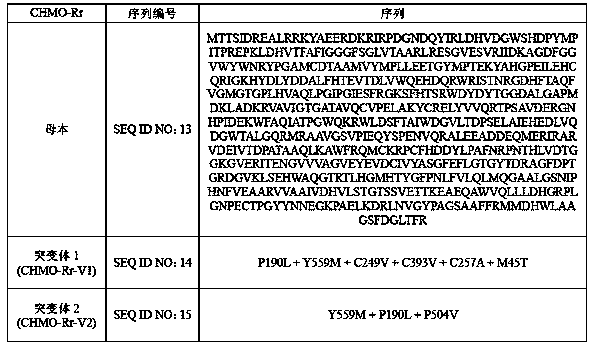

[0039] In the second typical embodiment of the present application, a method for preparing an immobilized enzyme is provided. The preparation method includes: using an activator to activate the cationic polymer to obtain an activated cationic polymer; combining the enzyme with the activated The cationic polymer is immobilized to obtain an immobilized enzyme; wherein, the activator is a polyol-unmodified cross-linking agent, a polyol-modified cross-linking agent or a cofactor, and the enzyme is selected from any one of the following: transaminase, ketoreductase, mono Oxygenase, ammonia lyase, ene reductase, imine reductase, amino acid dehydrogenase and nitrilase.

[0040] In the preparation method of the above-mentioned immobilized enzyme, the immobilized enzyme can be obtained by first activating PEI with glutaraldehyde or a cofactor, and then combining with the enzyme. The method is simple and is not easy to affect the activity of the enzyme during the immobilization process,...

Embodiment 1

[0085] Example 1: Preparation of glutaraldehyde-activated PEI covalently immobilized enzyme aggregates (GA: Glutaraldehyde, PEI: Polyethylene imine, GP: GA activated PEI, glutaraldehyde-activated PEI)

[0086] PEG-modified glutaraldehyde: dilute glutaraldehyde with water to a final concentration of 20 g / 100mL, add 2-10g / 100mL PEG 2000 or PEG 6000, mix at room temperature for 1-3 h and set aside.

[0087] Preparation of activated PEI solution 1: Add 2 g of glutaraldehyde and 4 g of PEI (3-70 KDa) to 100 mL of aqueous solution, pH 8.0, and stir for 3 h.

[0088] Preparation of activated PEI solution 2: add 4 g PEI (3 KDa) to 100 mL aqueous solution, pH 8.0, and PEG-modified glutaraldehyde (the final concentration of glutaraldehyde in the solution is 2 g / 100mL) and stir for 3 h .

[0089] Immobilization: 10 mL of enzyme (100-200 mg / mL enzyme protein content, correspondingly containing 3-10 mg / mL cofactor) was placed in a round bottom shaker flask, cooled to 5-10 °C, and mixed fo...

Embodiment 2

[0090] Example 2: Preparation of covalently immobilized enzyme aggregates in PEI activated by cofactors

[0091] Cofactor-activated PEI solution preparation: PEI (Mw=3-70 KDa) was diluted with water to a final PEI concentration of 1g / 100mL~2 g / 100mL and a pH value of 7.0~11.0. Depending on enzyme needs, add 3-10 mg / mL of each enzyme cofactor to the PEI solution and mix for 30-60 min at room temperature.

[0092] Immobilization: At 4-10 °C, add 7.5 mL of cofactor-activated PEI solution dropwise to 5 mL of enzyme solution (enzyme protein content is 30-80 mg / mL, correspondingly contains cofactor), mix for 30- After 60 min, add the cross-linking agent glutaraldehyde or PEG-modified glutaraldehyde, and make the final concentration of glutaraldehyde 0.2-1 g / 100mL. After mixing for 30-60 min, centrifuge to collect the insoluble precipitate, and pass through a 30-mesh sieve. After natural drying, the precipitate was soaked in 0.1 M PB (pH 7.0-8.0, containing 0.5-0.9M NaCl) for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com