Synthesis method of nitroazole energetic compound

A synthesis method and compound technology are applied in the synthesis field of nitrogen nitration products, which can solve problems such as lack of overall reaction mechanism, and achieve the effects of simple reaction process, good substrate universality and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

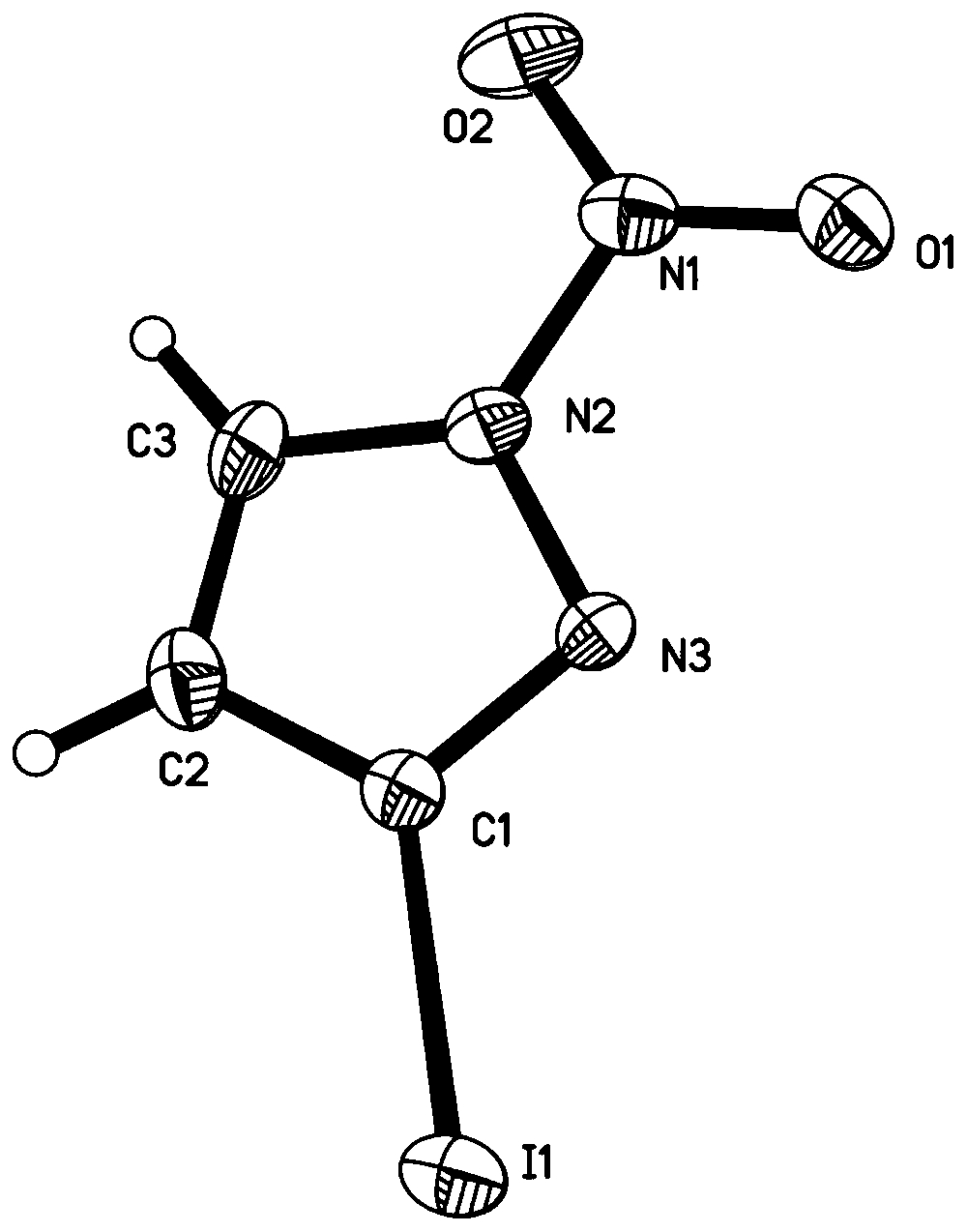

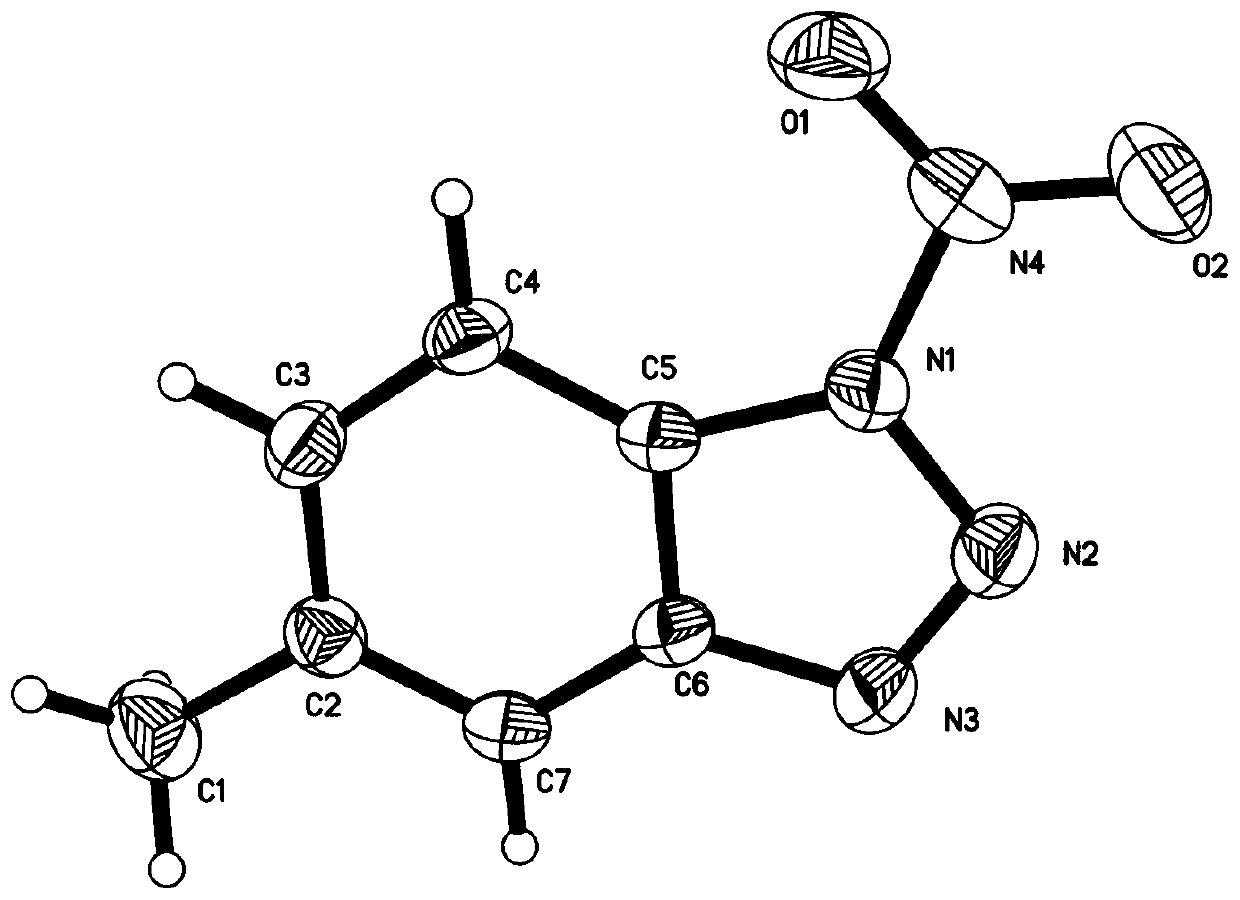

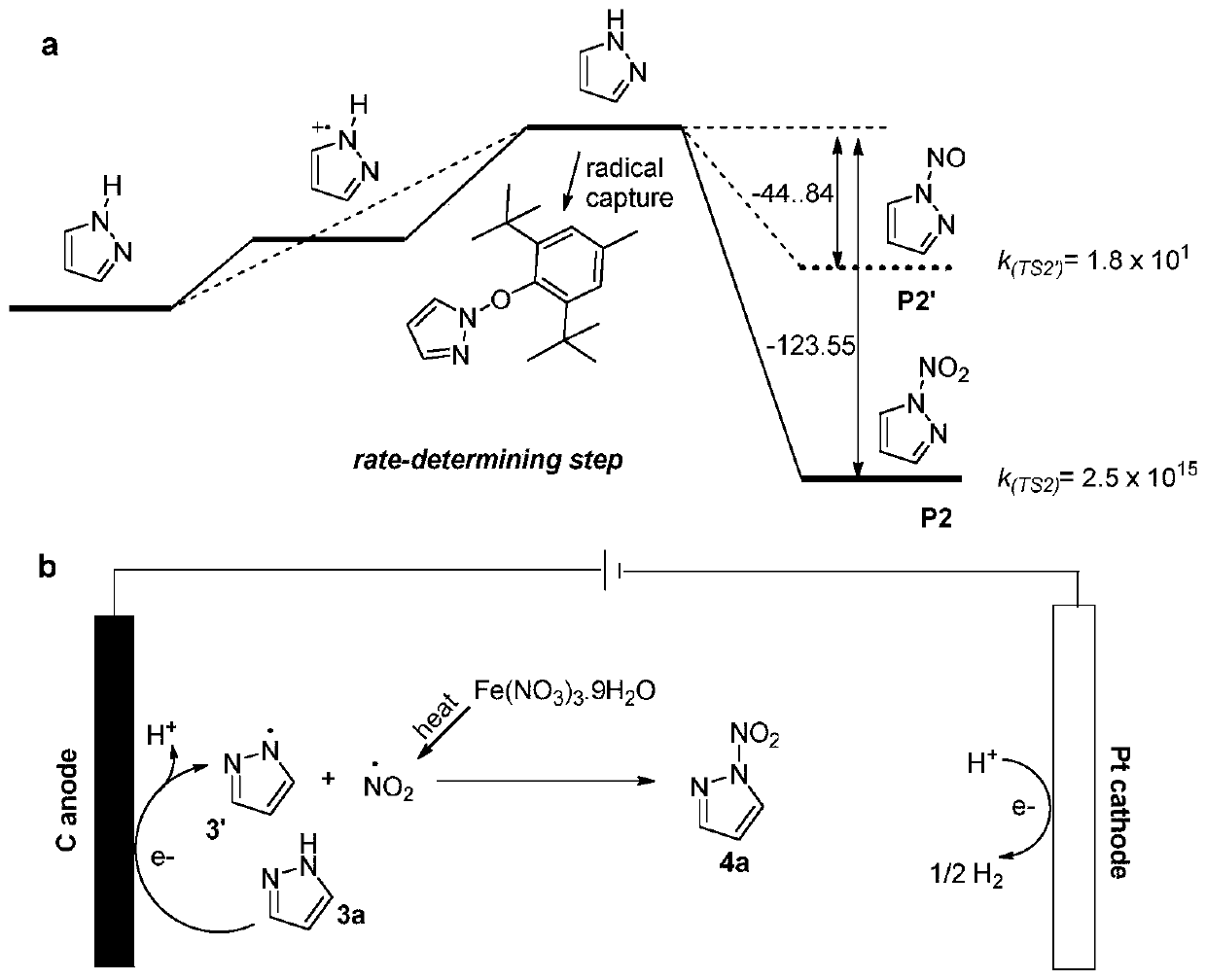

[0030] Synthesis of N-nitropyrazole

[0031]

[0032] In a three-necked flask (25 mL) after drying in an oven equipped with a stir bar, add pyrazole (1.0 mmol, 68 mg), electrolyte n-Bu 4 NBF 4 (205mg, 0.6mmol) and ferric nitrate nonahydrate (2.0mmol, 0.808g). The three-necked flask is equipped with a graphite rod (Φ=6mm) as the anode, platinum electrode (10mm×10mm) as the cathode, and 16mL CH 3 CN, then evacuated and flushed with nitrogen as a protective gas. The reaction mixture was stirred and refluxed at a constant current of 15 mA and 70°C for 6 hours. When the reaction was completed, the reaction mixture was washed twice with water and extracted with ethyl acetate (10 mL×3). Then combine the organic layers and use Na 2 SO 4 After drying, it was concentrated in vacuo, and then passed through a flash chromatography column to obtain the pure product, which was a white powdery solid with a yield of 64%. The NMR characterization of the product was: 1 H NMR (500MHz, Chloroform-d)...

Embodiment 2

[0034] Synthesis of N-nitropyrazole

[0035]

[0036] The reaction steps are exactly the same as in Example 1, except that tetrabutylamine tetrafluoroborate is changed to tetrabutylamine perchlorate. The product is a white powdery solid with a yield of 53%. The nuclear magnetic characterization of the product is : 1 H NMR (500MHz, Chloroform-d) δ = 8.36 (d, J = 2.8, 1H), 7.66 (s, 1H), 6.55-6.48 (m, 1H). 13 C NMR (126MHz, Chloroform-d) δ=140.98, 125.24, 109.36.

Embodiment 3

[0038] Synthesis of N-nitropyrazole

[0039]

[0040] The reaction steps are exactly the same as in Example 1, except that ferric nitrate nonahydrate is changed to bismuth nitrate pentahydrate, the product is a white powdery solid, and the yield is 43%. The NMR characterization of the product is: 1 H NMR (500MHz, Chloroform-d) δ = 8.36 (d, J = 2.8, 1H), 7.66 (s, 1H), 6.55-6.48 (m, 1H). 13 C NMR (126MHz, Chloroform-d) δ=140.98, 125.24, 109.36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com