A high-throughput method for powder alloy preparation and thermal consolidation forming process development

A forming process and powder alloy technology, which is applied in the high-throughput field of powder alloy preparation and thermal consolidation forming process development, can solve the problems of long cycle, high cost, and continuous expansion, and achieve the effect of short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

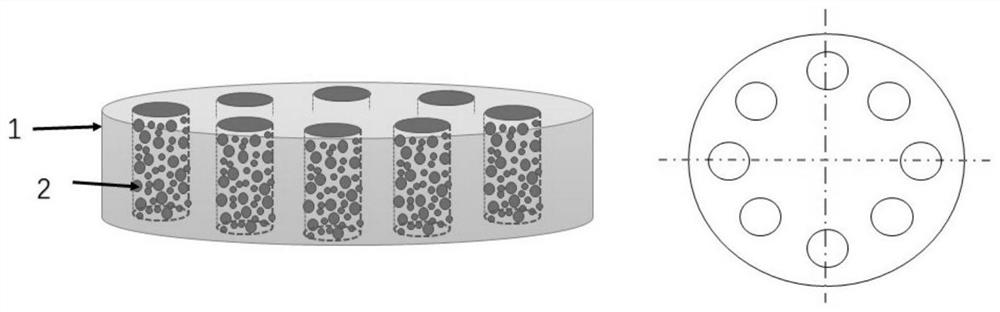

[0043] This implementation case is a nickel alloy high-throughput composition design and hot extrusion process development steps are:

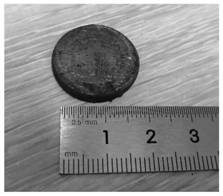

[0044] (1) adopt argon gas atomization to prepare nickel alloy powder, powder composition Ni-21Cr-0.7Fe-0.6Ti-0.3Al, cross 100 mesh sieves;

[0045] (2) Put the powder into a bag and shake it;

[0046] (3) The sheath is sealed and welded by vacuum electron beam;

[0047] (4) Use a thermal simulation testing machine to conduct a thermal compression simulation test, the thermal compression temperature is 850°C, 950°C, 1050°C, 1150°C, and the strain rate is 1S -1 , 0.1S -1 、5S -1 , the deformation amount is 80%, and the alloy small block is obtained;

[0048] (6) Observe the macroscopic surface conditions of the sample, such as Figure 5 As shown, the hot-pressing temperature of 850℃ alloy is all cracked, and the strain rate is 5S -1 Cracking occurs at a temperature of 950°C. When the temperature is too low, the deformation resistance becom...

Embodiment 2

[0052] This implementation case is a nickel alloy high-throughput composition design and hot extrusion process development steps are:

[0053] (1) Nickel alloy powder is prepared by argon atomization, and the powder composition is Ni-21Cr-0.7Fe-0.6Ti-0.3Al;

[0054] (2) Nickel alloy powder with 0.6% YH 2 The powder is ball milled, using argon protection during the ball milling process, adding 0.5% ethanol as a process control agent, ball milling for 36 hours, and passing through a 50-mesh sieve after ball milling;

[0055] (3) Put the ball mill powder into the bag and shake it;

[0056] (4) The sheath is sealed and welded by vacuum electron beam;

[0057] (5) Use a thermal simulation testing machine to conduct a thermal compression simulation test, the thermal compression temperature is 850°C, 950°C, 1050°C, 1150°C, and the strain rate is 1S -1 , 0.1S -1 、5S -1 , the deformation amount is 80%, and the alloy small block is obtained;

[0058] (6) Observe the macroscopic su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com