High-flux method for powder alloy preparation and thermal consolidation forming process development

A forming process and powder alloy technology, which is applied in the high-throughput field of powder alloy preparation and thermal consolidation forming process development, can solve the problems of unverified accuracy of simulation, coarse second phase, and easy-to-crack available materials, etc., to achieve sufficient The effect of accurate data guidance, shortening the test cycle, and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

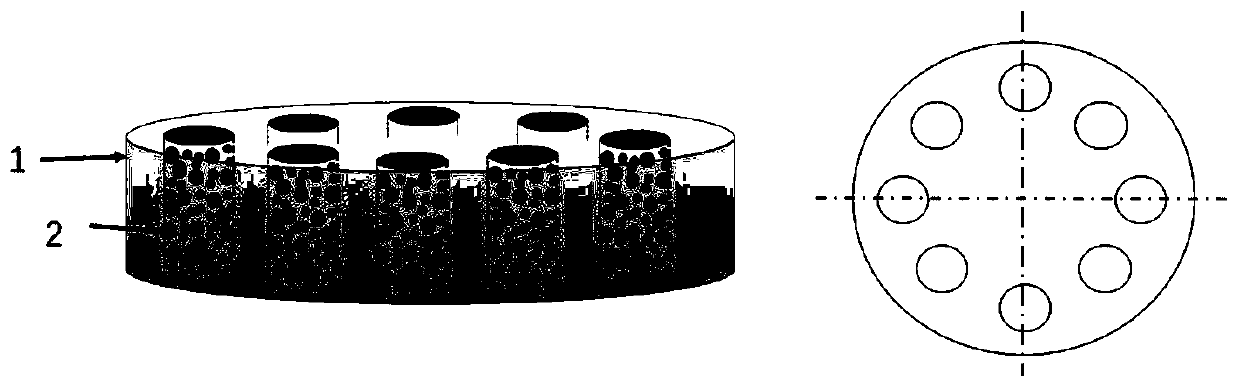

Image

Examples

Embodiment 1

[0043] This implementation case is a nickel alloy high-throughput composition design and hot extrusion process development steps are:

[0044] (1) adopt argon gas atomization to prepare nickel alloy powder, powder composition Ni-21Cr-0.7Fe-0.6Ti-0.3Al, cross 100 mesh sieves;

[0045] (2) Put the powder into a bag and shake it;

[0046] (3) The sheath is sealed and welded by vacuum electron beam;

[0047] (4) Use a thermal simulation testing machine to conduct a thermal compression simulation test, the thermal compression temperature is 850°C, 950°C, 1050°C, 1150°C, and the strain rate is 1S -1 , 0.1S -1 、5S -1 , the deformation amount is 80%, and the alloy small block is obtained;

[0048] (6) Observe the macroscopic surface conditions of the sample, such as Figure 5 As shown, the hot-pressing temperature of 850℃ alloy is all cracked, and the strain rate is 5S -1 Cracking occurs at a temperature of 950°C. When the temperature is too low, the deformation resistance becom...

Embodiment 2

[0052] This implementation case is a nickel alloy high-throughput composition design and hot extrusion process development steps are:

[0053] (1) Nickel alloy powder is prepared by argon atomization, and the powder composition is Ni-21Cr-0.7Fe-0.6Ti-0.3Al;

[0054] (2) Nickel alloy powder with 0.6% YH 2 The powder is ball milled, using argon protection during the ball milling process, adding 0.5% ethanol as a process control agent, ball milling for 36 hours, and passing through a 50-mesh sieve after ball milling;

[0055] (3) Put the ball mill powder into the bag and shake it;

[0056] (4) The sheath is sealed and welded by vacuum electron beam;

[0057] (5) Use a thermal simulation testing machine to conduct a thermal compression simulation test, the thermal compression temperature is 850°C, 950°C, 1050°C, 1150°C, and the strain rate is 1S -1 , 0.1S -1 、5S -1 , the deformation amount is 80%, and the alloy small block is obtained;

[0058] (6) Observe the macroscopic su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com