Bioremediation system for organic contaminated site

A technology for bioremediation and organic pollution, applied in the restoration of polluted soil, etc., can solve the problems of inapplicability, high cost of inoculum, difficult to realize the movable and assembling of restoration equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

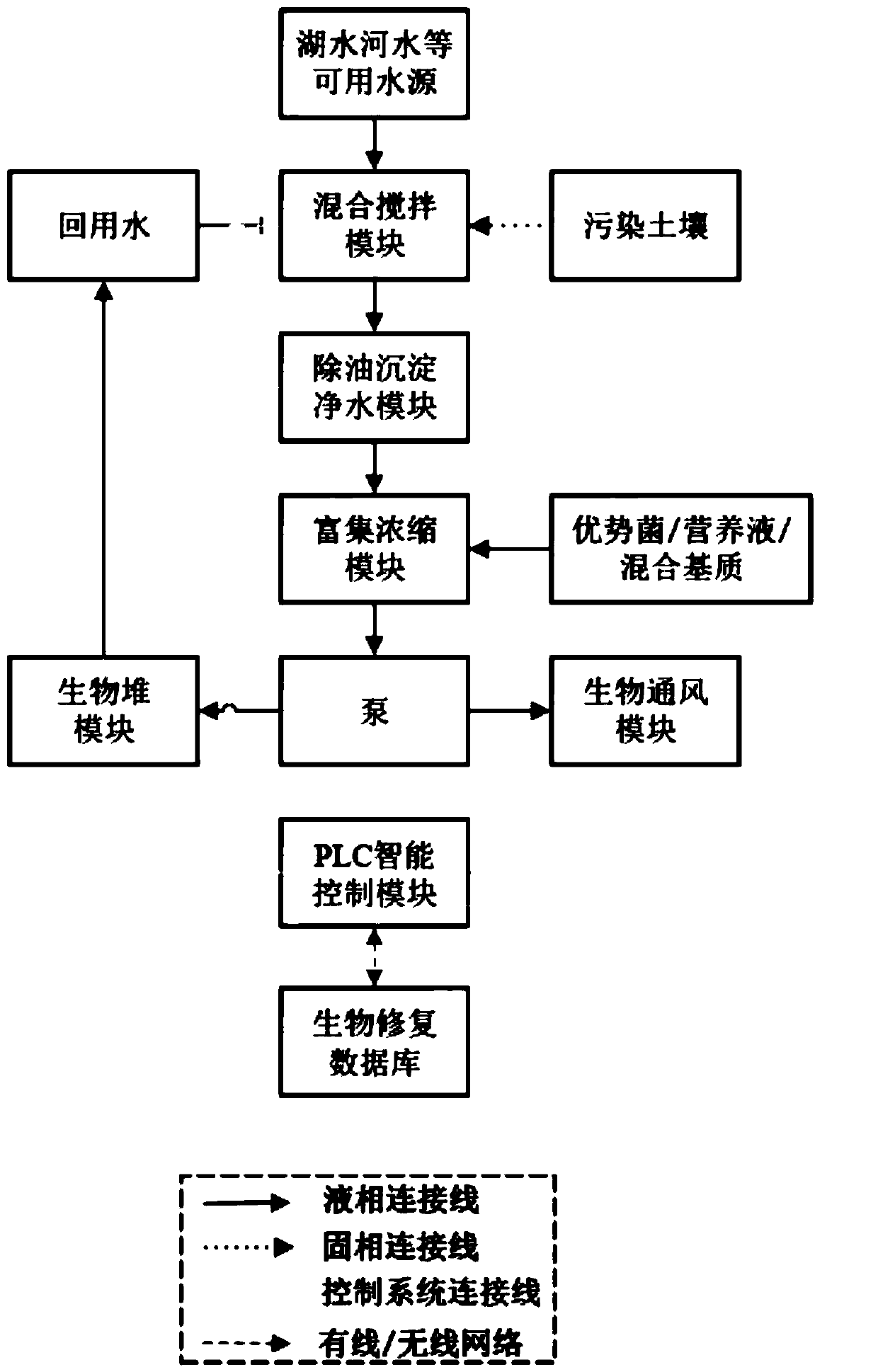

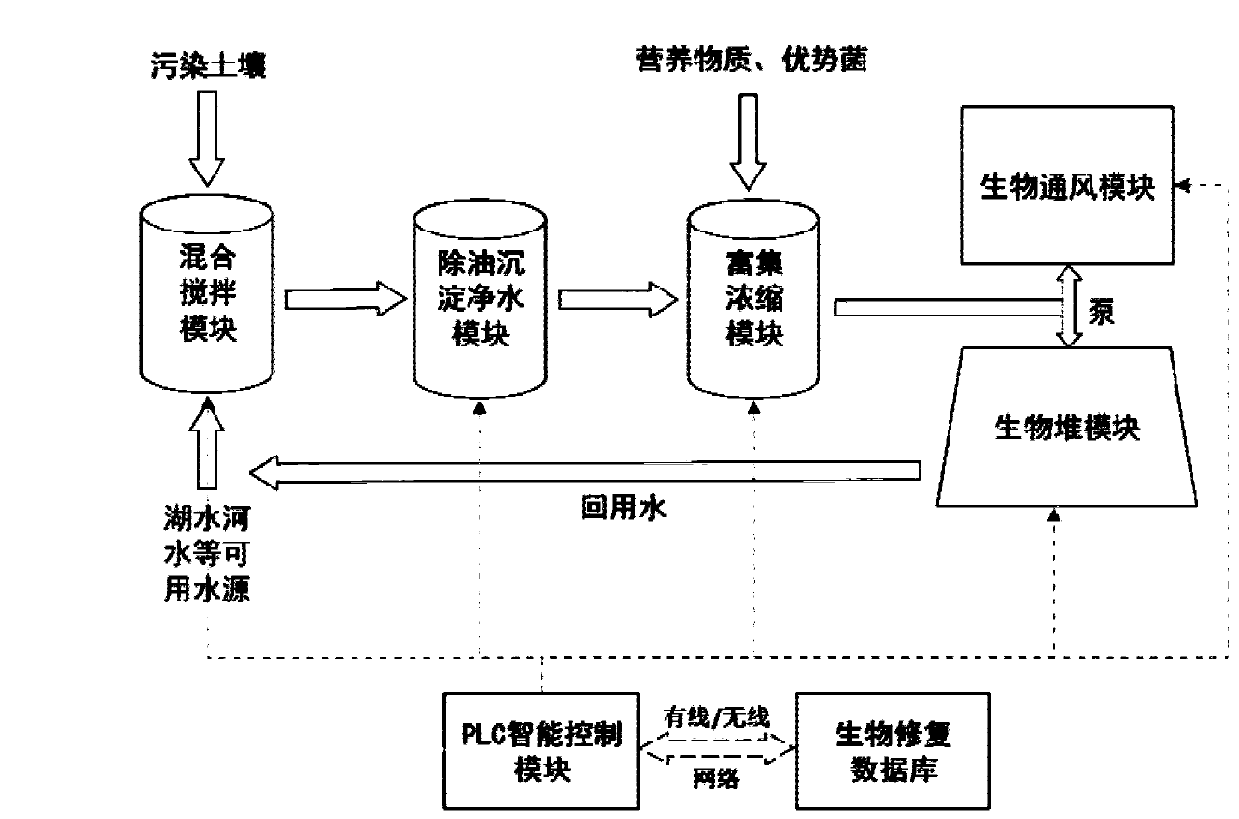

[0042] Such as figure 1 , figure 2 As shown, a bioremediation system for organic polluted sites, including: mixing and stirring module, oil removal and sedimentation water purification module, enrichment and concentration module, bacterial agent / nutrient solution / mixed matrix injection module (pump), biological ventilation / biological stack module , PLC intelligent control module, bioremediation database module.

[0043] The mixing and stirring module is used to mix the available water sources such as polluted soil, lake water and river water, and the reused water treated by the biopile system, and fully stir to make the indigenous degrading bacteria contained in the polluted soil and some pollutants in the soil enter the water body, wherein the soil water The ratio should not be greater than 2:1. These indigenous microorganisms have better tolerance and adaptability under the conditions of the polluted site, and their ability to degrade the site pollutants is stronger.

[...

Embodiment 1

[0054] The area of polluted soil in a certain site is small, the pollution is light, the soil has good water permeability, and the pollutants are volatile to a certain extent, requiring in-situ treatment. Digging, and thus choose the biological ventilation system. During this period, the system of the present invention is arranged in the polluted site, and the diameter of the operating well in this area needs to be limited to 60-150mm, and the depth is 1-10m. First, take a certain amount of polluted soil (100g ~ 10000g) and water source into the mixing and stirring module, after the degreasing and sedimentation water purification module, it is passed into the enrichment and concentration module, during which the dominant bacteria, nutrient solution and mixed matrix are introduced to enrich and cultivate microorganisms for 15 After ~30 days, slowly pump into the soil layer of the biological ventilation system. During this period, the injection well continuously feeds air and ...

Embodiment 2

[0056] A polluted site has a high concentration of pollutants, is difficult to degrade, has a large scale, and requires a short construction period. Therefore, it chooses to repair in situ. For the filtrate collection pipeline, take a certain amount of polluted soil (1000g~10000g) and water source and add it to the mixing and stirring module. After cultivating microorganisms for 15-30 days, slowly pump them into the biopile system (continuous spraying), control the soil water holding rate between 70% and 90%, control the pH between 6.5 and 8.0, and control the oxygen content of the pile at 7% and Above, the microbial content is not less than 10 5 During this period, excess water is passed into the water purification device through the leachate collection pipeline, and after treatment, it flows back to the mixing module. The gas is pumped to the air purification system through the exhaust system, and is discharged to the air after the treatment reaches the standard.

[0057] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com