High-temperature-resistant aluminum oxide nanocrystal aerogel material and preparation method thereof

A nano-alumina, aerogel technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve problems such as hole reduction, thermal insulation failure, application limitations, etc., to achieve sufficient coating process. , good temperature resistance, small shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

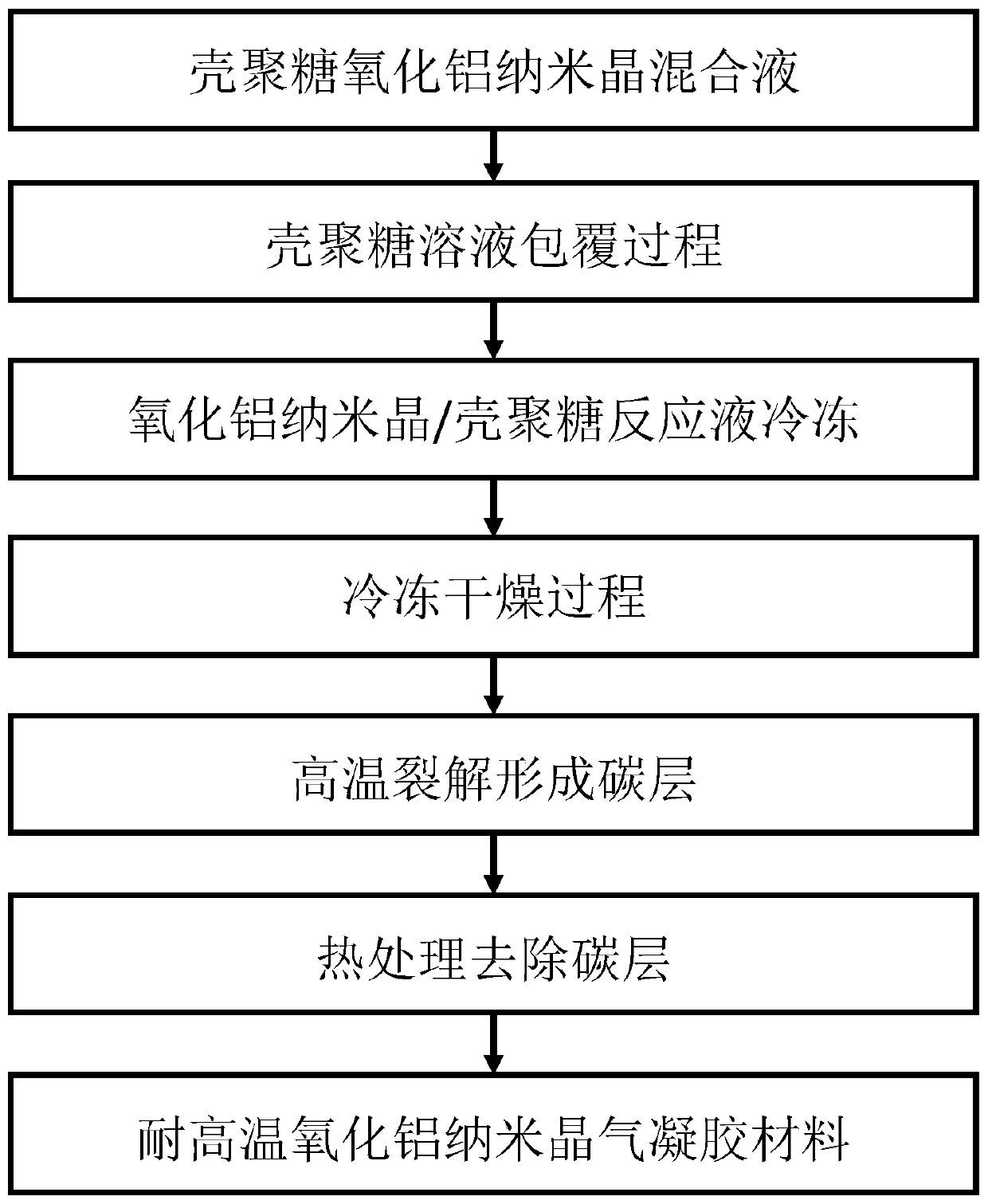

[0036] The present invention provides, in a first aspect, a method for preparing a high temperature resistant alumina nanocrystalline aerogel material, the method comprising the following steps:

[0037] (1) Mix the alumina nanocrystal dispersion with the chitosan solution uniformly to obtain a mixed solution; in the present invention, for example, the alumina nanocrystal dispersion and the chitosan solution are mixed by stirring and ultrasonic treatment In the present invention, the aluminum oxide nanocrystal dispersion is prepared by dissolving aluminum oxide nanocrystals in water, and the mass fraction of aluminum oxide nanocrystals contained in the aluminum oxide nanocrystal dispersion (mass concentration) can be, for example, 8-12%, preferably 10%; in the present invention, the chitosan solution can be, for example, an aqueous chitosan solution.

[0038](2) adding glacial acetic acid to the mixed solution obtained in step (1) to dissolve the chitosan contained in the mixe...

Embodiment 1

[0065] S1. Mix 10 g of alumina nanocrystal dispersion with a mass fraction of 10% and 20 g of a chitosan solution with a mass fraction of 2%, fully stir, and ultrasonicate for 1 h to obtain a mixed solution; wherein, the alumina nanocrystal dispersion adopts a diameter of 120nm, 2μm length of alumina nanorods prepared.

[0066] S2. Add a certain amount of (purity 99%) glacial acetic acid (0.4 g) to the mixed solution obtained in step S1, fully stir to dissolve the chitosan, and form a mixed solution of chitosan alumina nanocrystals, which is heated at 80°C 6h to obtain the chitosan dispersion of alumina nanocrystals.

[0067] S3, vacuumize the alumina nanocrystal chitosan dispersion liquid obtained in step S2 at a temperature of 25° C. and a vacuum degree of 0.25 MPa for 0.5 h to obtain an alumina nanocrystal / chitosan reaction solution.

[0068] S4. Freeze the alumina nanocrystal / chitosan reaction solution obtained in step S3, and the freezing condition is freezing under liqu...

Embodiment 2

[0074] Example 2 is basically the same as Example 1, except that the amount of the alumina nanocrystal dispersion liquid in step S1 is 20 g.

[0075] In Example 2, the heat-resistant alumina nanocrystalline aerogel material was tested for thermal insulation performance, and it was found that the surface of the high-temperature resistant alumina nanocrystalline aerogel material had no loss of light, no discoloration, and no shedding, and other performance indicators were shown in Table 1. shown.

[0076] The linear shrinkage rate of the high temperature-resistant alumina nanocrystalline aerogel material prepared in this example after heat treatment at 1400° C. for 1 h in an air atmosphere is 5.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com