Preparation method of high-performance structural material based on carbonation

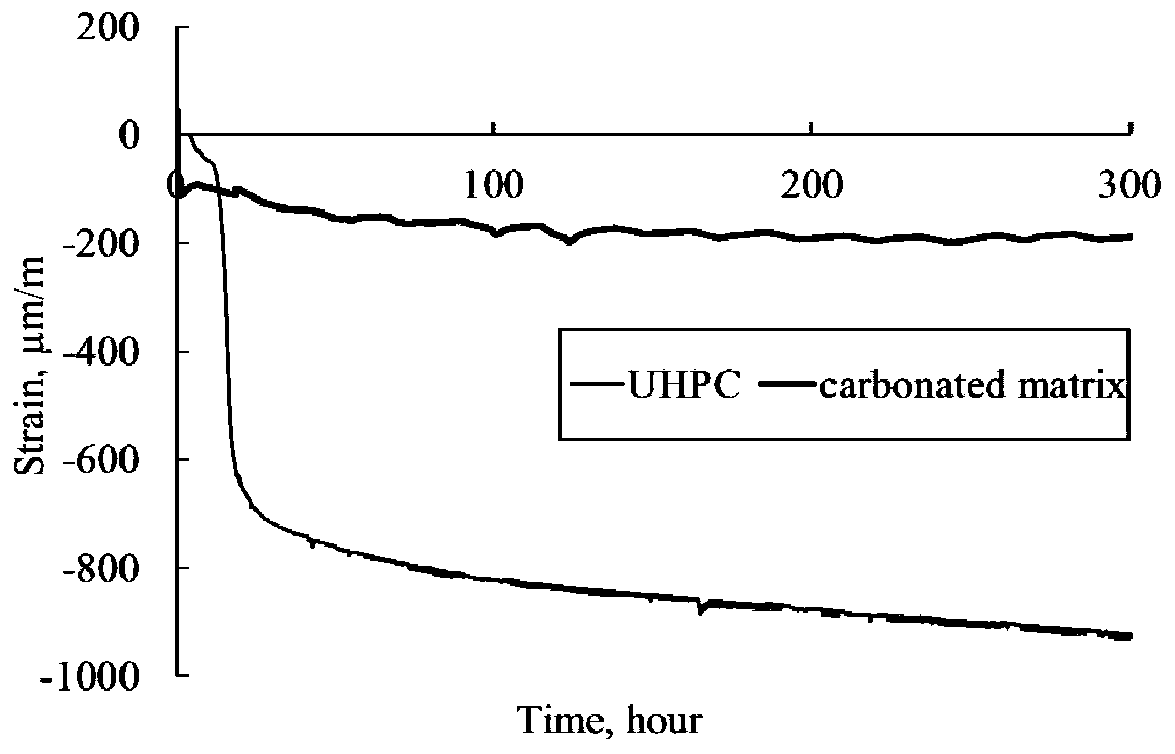

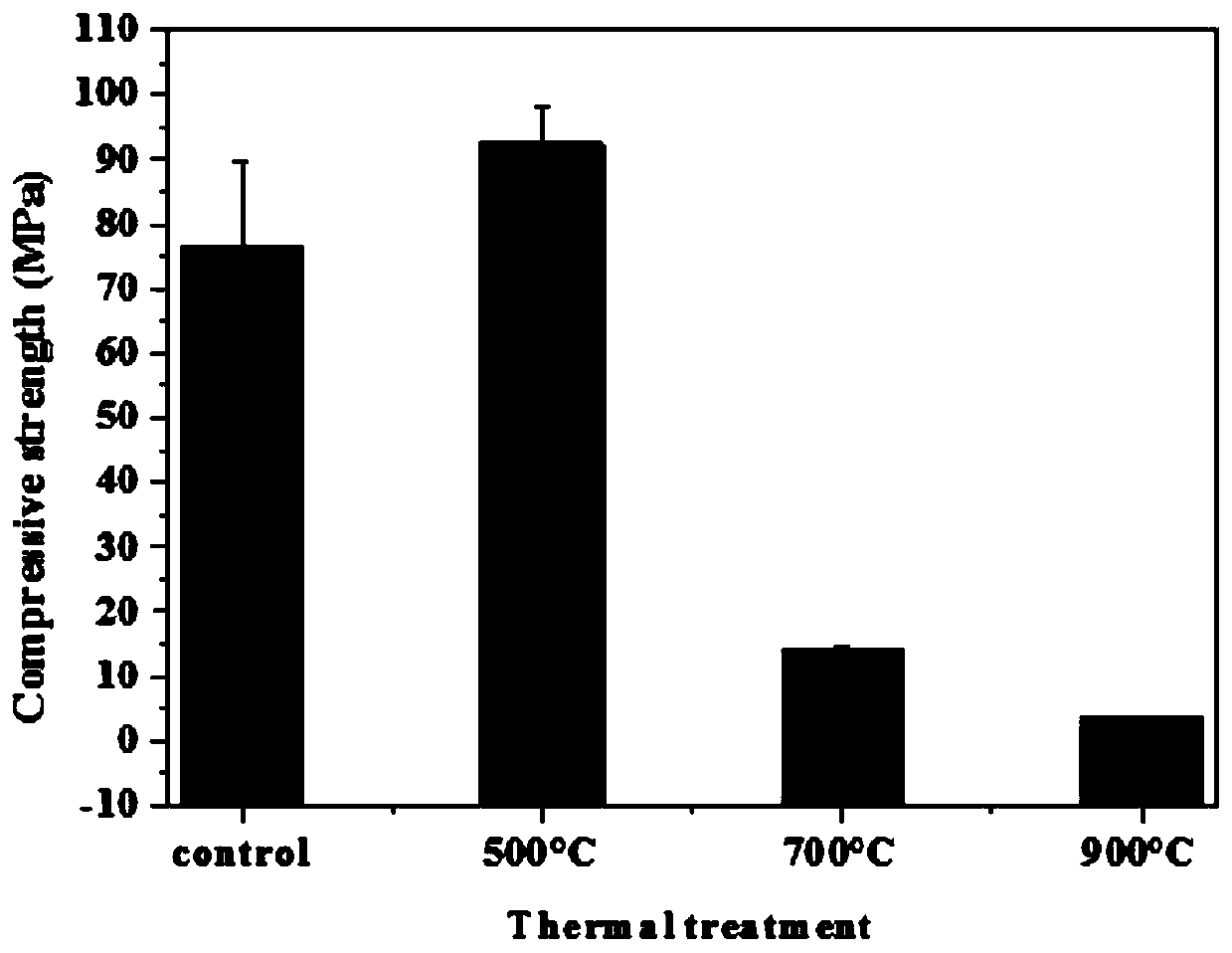

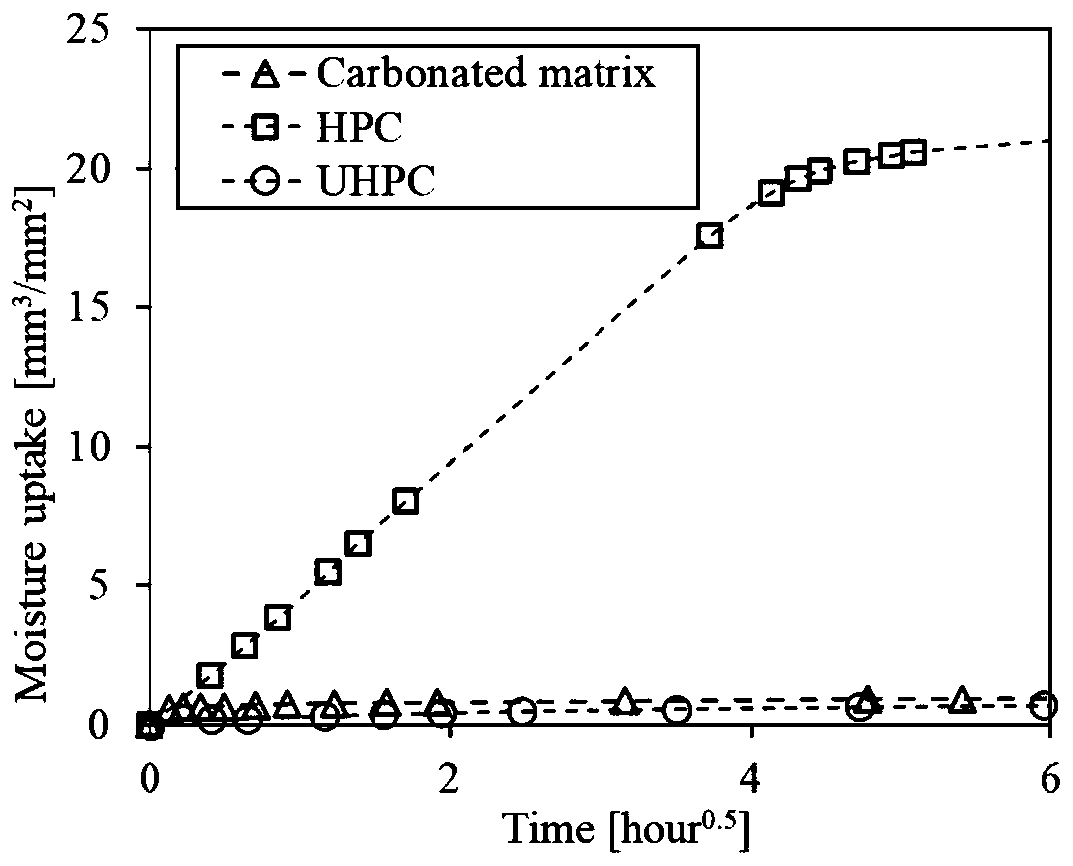

A structural material and carbonation technology, applied in the field of building materials, can solve the problems of low thermal stability and corrosion resistance of C-S-H gel, and achieve the effect of excellent mechanical properties and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a high-performance structural material based on carbonation, specifically comprising the following steps:

[0029] 1) Clinker firing: crushing, mixing and grinding calcareous raw materials (limestone) and siliceous raw materials (sandstone) to obtain a raw meal with a calcium-silicon ratio of 1.80; calcining the raw meal in a rotary kiln (the calcining temperature is 1350°C), cooling by a grate cooler (cooling rate is 350°C / min), and then grinding to obtain a Burger specific surface area of 345m 2 / kg of ground clinker;

[0030] 2) Forming of green body: According to the mass percentage, mix 70% finely ground clinker, 25% quartz sand, and 5% water reducer, add tap water and stir evenly, then pour the size of 50×50×100cm 3 pouring and molding in a mold, and pre-cured for 24 hours at 40°C and 100% humidity, and then demolded and carried out infrared drying to obtain a pouring molding green body with a moisture content of 15%, wherein the amount o...

Embodiment 2

[0038] A method for preparing a high-performance structural material based on carbonation, specifically comprising the following steps:

[0039] 1) Clinker firing: crushing, mixing and grinding calcareous raw materials (limestone) and siliceous raw materials (sandstone) to obtain a raw meal with a calcium-silicon ratio of 1.93; calcining the raw meal in a rotary kiln (calcination temperature is 1350°C), cooling by a grate cooler (cooling rate is 150°C / min), and then grinding to obtain a Burger specific surface area of 365m 2 / kg of ground clinker;

[0040] 2) Forming of green body: According to the mass percentage, after mixing 50% finely ground clinker and 50% quartz sand, add tap water and stir evenly, then pour the 3 In the mold, and under the molding pressure of 30MPa for 3min, the mixture is pressed and molded to obtain a pressed molded body, wherein the amount of water added is 15% of the mass of the ground clinker, and the quartz sand is composed of an average partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com