SiCf-ZrC-ZrB2 ceramic composite powder and preparation method thereof

A ceramic composite and powder technology, applied in the field of ceramic materials, can solve the problems of high cost and complex preparation method, and achieve the effects of low cost, simple and reliable process, and controllable scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

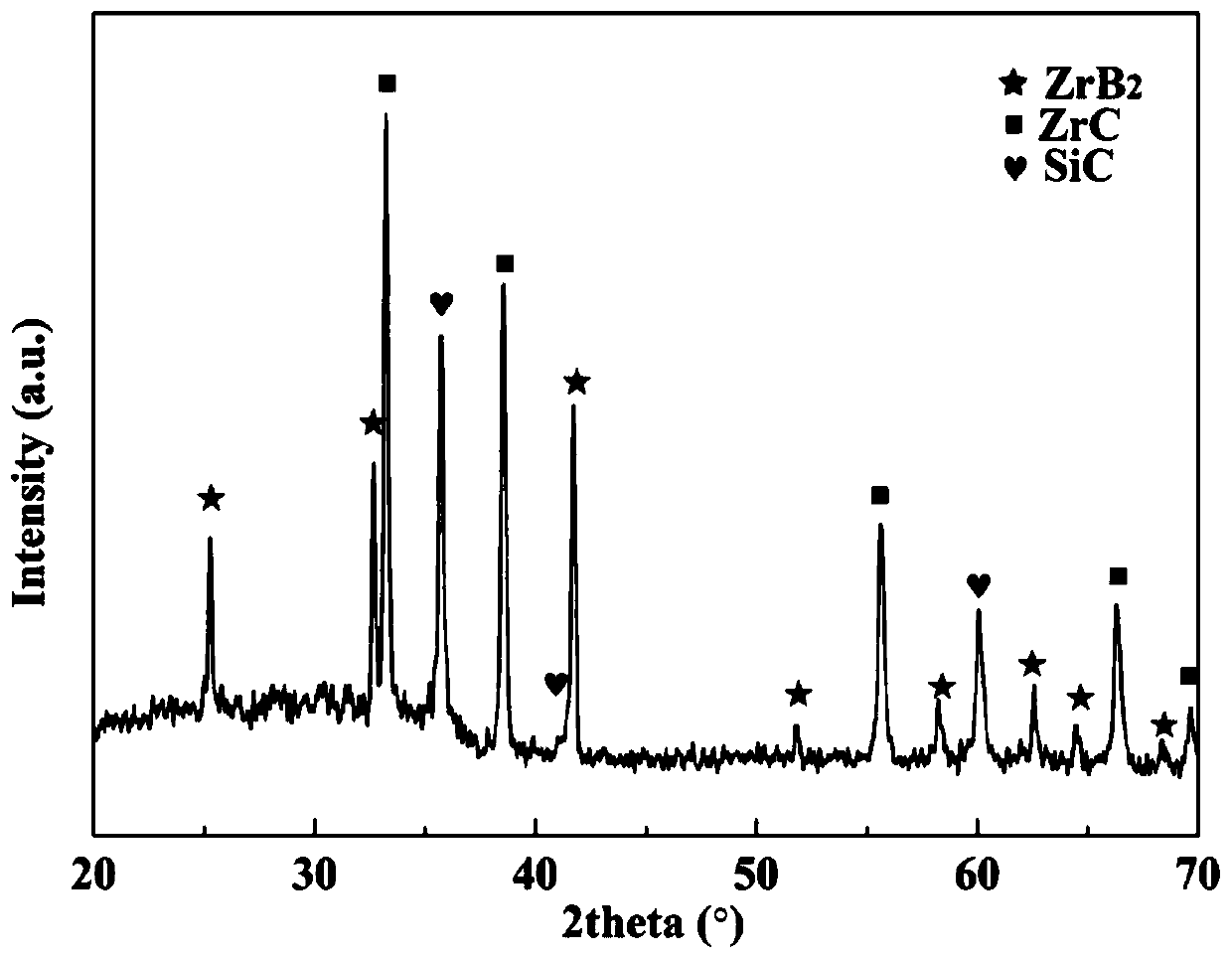

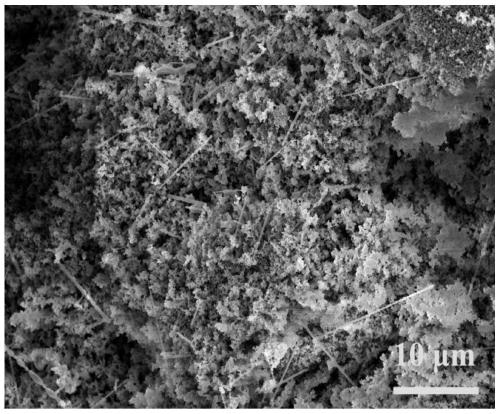

Examples

Embodiment 1

[0027] (1) Configuration of the zirconium precursor solution: Weigh 3.2 g of zirconium oxychloride according to the molar weight of 0.01 mol for later use, dissolve the zirconium oxychloride in 20 mL of absolute ethanol, and stir evenly to obtain the zirconium precursor solution;

[0028] (2) Configuration of silicon precursor solution: According to the molar ratio of zirconium oxychloride and ethyl orthosilicate 1:5, weigh 10.4g of ethyl orthosilicate and dissolve it in 15mL of absolute ethanol, stir evenly to obtain silicon precursor Solution; wherein the volume ratio of ethyl tetrasilicate and dehydrated alcohol is 1:4;

[0029] (3) Preparation of silicon-zirconium precursor solution: under continuous magnetic stirring, add the silicon precursor solution prepared in step 2 to the zirconium precursor solution dropwise, add 0.05mL polyethylene glycol dropwise, and stir evenly to obtain Silicon zirconium precursor solution;

[0030] (4) Preparation of borosilicate-zirconium p...

Embodiment 2

[0035](1) Configuration of the zirconium precursor solution: Weigh 6.4 g of zirconium oxychloride according to the molar weight of 0.02 mol for later use, dissolve the zirconium oxychloride in 30 mL of absolute ethanol, and stir evenly to obtain the zirconium precursor solution;

[0036] (2) Configuration of the silicon precursor solution: according to the molar ratio of zirconium oxychloride and ethyl orthosilicate 1:4, weigh 16.6g of ethyl orthosilicate and dissolve it in 15mL of absolute ethanol, and stir evenly to obtain the silicon precursor body solution;

[0037] (3) Preparation of silicon-zirconium precursor solution: under continuous magnetic stirring, add the silicon precursor solution prepared in step 2 to the zirconium precursor solution dropwise, add 0.05mL polyethylene glycol dropwise, and stir evenly to obtain Silicon zirconium precursor solution;

[0038] (4) Preparation of borosilicate-zirconium precursor solution: Weigh 2.5g of boric acid and 14.4g of glucos...

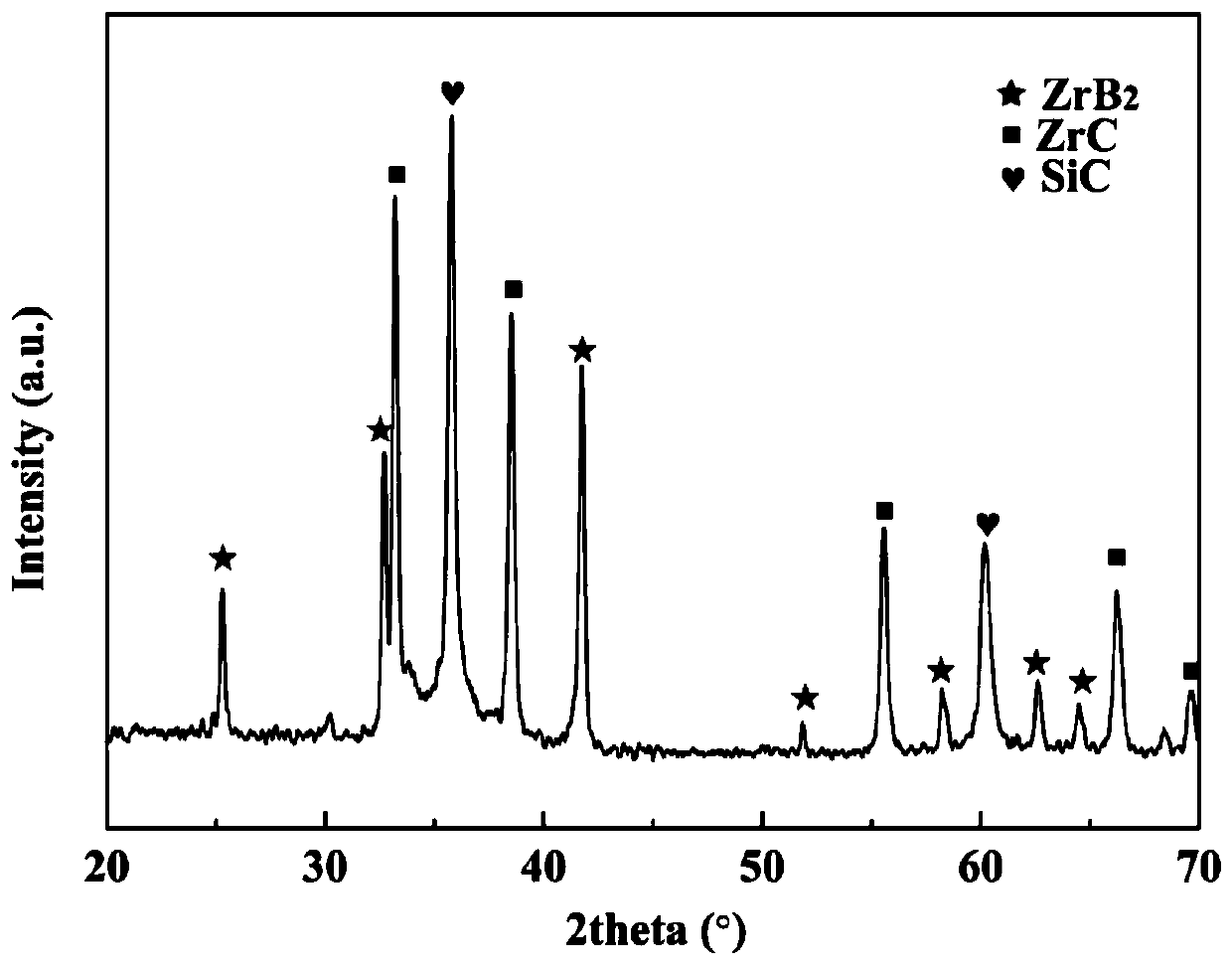

Embodiment 3

[0043] (1) Configuration of the zirconium precursor solution: Weigh 3.2 g of zirconium oxychloride according to the molar weight of 0.01 mol for later use, dissolve the zirconium oxychloride in 20 mL of absolute ethanol, and stir evenly to obtain the zirconium precursor solution;

[0044] (2) Configuration of the silicon precursor solution: According to the molar ratio of zirconium oxychloride and ethyl orthosilicate 1:4, weigh 8.32g of ethyl orthosilicate and dissolve it in 10mL of absolute ethanol, stir evenly to obtain the silicon precursor body solution; wherein the volume ratio of ethyl tetrasilicate and dehydrated alcohol is 1:3;

[0045] (3) Preparation of silicon-zirconium precursor solution: under continuous magnetic stirring, add the silicon precursor solution prepared in step 2 to the zirconium precursor solution dropwise, add 0.05mL polyethylene glycol dropwise, and stir evenly to obtain Silicon zirconium precursor solution;

[0046] (4) Preparation of borosilicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com