Polymer composite material and preparation method of filter cavity

A technology of composite materials and polymer matrix, which is applied in the field of preparation of polymer composite materials and filter cavities, can solve the problems that it is difficult to effectively control the surface roughness of the product, and the product is difficult to meet the requirements of the communication industry, so as to achieve light weight Quantification, density reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

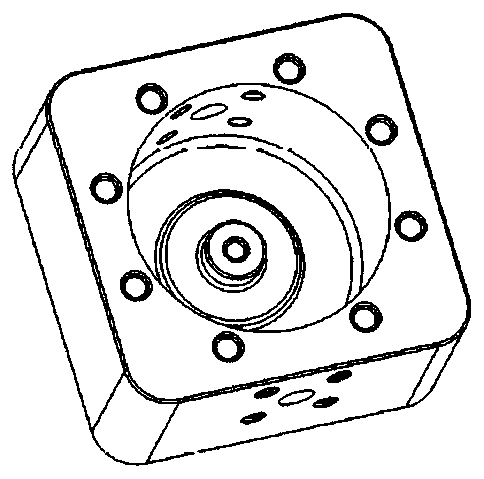

[0037] A method for preparing a cavity of a polymer composite material based on the above polymer composite material, comprising the following steps:

[0038] (1) Processing the polymer composite material into a cavity body through a molding process; wherein, the mass content of the reinforcing material in the cavity body is 5-85 wt %;

[0039] The composite material includes a polymer matrix and a reinforcing material in terms of mass percentage, the reinforcing material has a mass content of 5 to 85 wt%, and the reinforcing material is uniformly dispersed in the polymer matrix;

[0040] The molding process is one or more combinations of injection molding, extrusion, powder metallurgy, turning, molding and grinding.

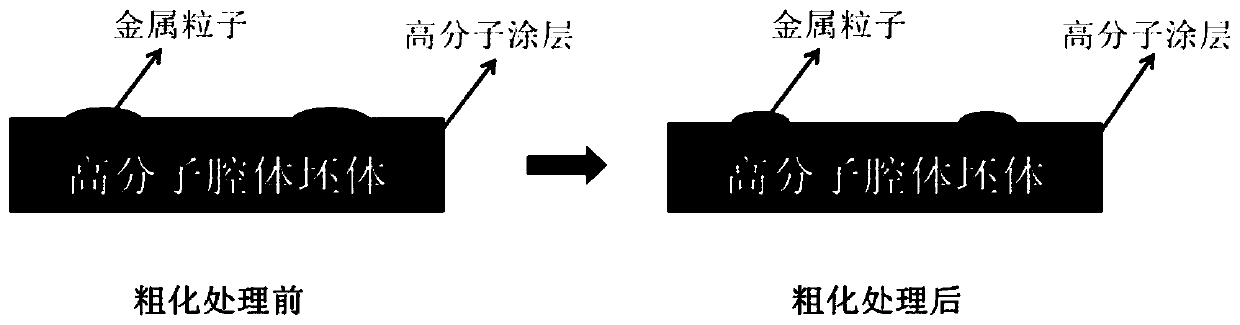

[0041] (2) The cavity embryo body is subjected to a surface activation treatment process to make it have good surface roughness and surface activity; see figure 2 .

[0042] Among them, the surface activation process is divided into two parts. First, the coat...

Embodiment 1

[0050] The filter cavity is prepared by using glass fiber reinforced polyetherimide (PEI) as a polymer composite material, wherein the glass fiber reinforced polyetherimide (PEI) is a polymer composite material including a polymer matrix and a reinforcing material; The molecular matrix is polyetherimide, with a mass content of 55%; the reinforcing material is a mixture of glass fiber and mineral powder, with a mass content of 45%, and the thermal expansion coefficient of the composite material is 25×10 -6 / °C.

[0051] The PEI composite material is injection-molded into a cavity blank of the polymer composite material, and is ready for use after deburring treatment.

[0052] Dissolve PEI in N-methylpyrrolidone under heating conditions, and add metal silver powder and surfactant (OP emulsifier) with a particle size of 15 microns (D 90) to it, and make it after fully stirring evenly PEI coatings containing metallic silver particles.

[0053] The PEI paint containing metall...

Embodiment 2

[0057] The filter cavity is prepared with glass fiber reinforced polyphenylene sulfide (PPS) as a polymer composite material, wherein the polymer matrix is polyphenylene sulfide, and its content is 65%; the reinforcement material is carbon fiber and mineral powder, and its mass The content is 35%, and the thermal expansion coefficient of the composite material is 18×10 -6 / °C.

[0058] The PPS composite material is injection-molded into a cavity blank of a polymer composite material, and is ready for use after deburring treatment.

[0059] Dissolve PPS powder in sulfolane under heating conditions, and add metal copper powder and surfactant (OP emulsifier) with a particle size of 18 microns (D 90) to it, and make it after thorough stirring. into paint.

[0060] The PPS paint containing metallic silver particles is evenly sprayed on the surface of the polymer cavity, and the thickness of the coating is controlled to be 15 microns.

[0061] The sprayed polymer cavity compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com