A kind of water-based yellow ceramic ink for inkjet printing and preparation method thereof

A ceramic ink and inkjet printing technology, which is applied in ink, applications, household appliances, etc., can solve the problems of single color tone and limited use of yellow ceramic ink/ink, and achieve enhanced activity of reactants, excellent color performance, and enhanced absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of ink-jet printing water-based yellow ceramic ink, its preparation comprises the steps:

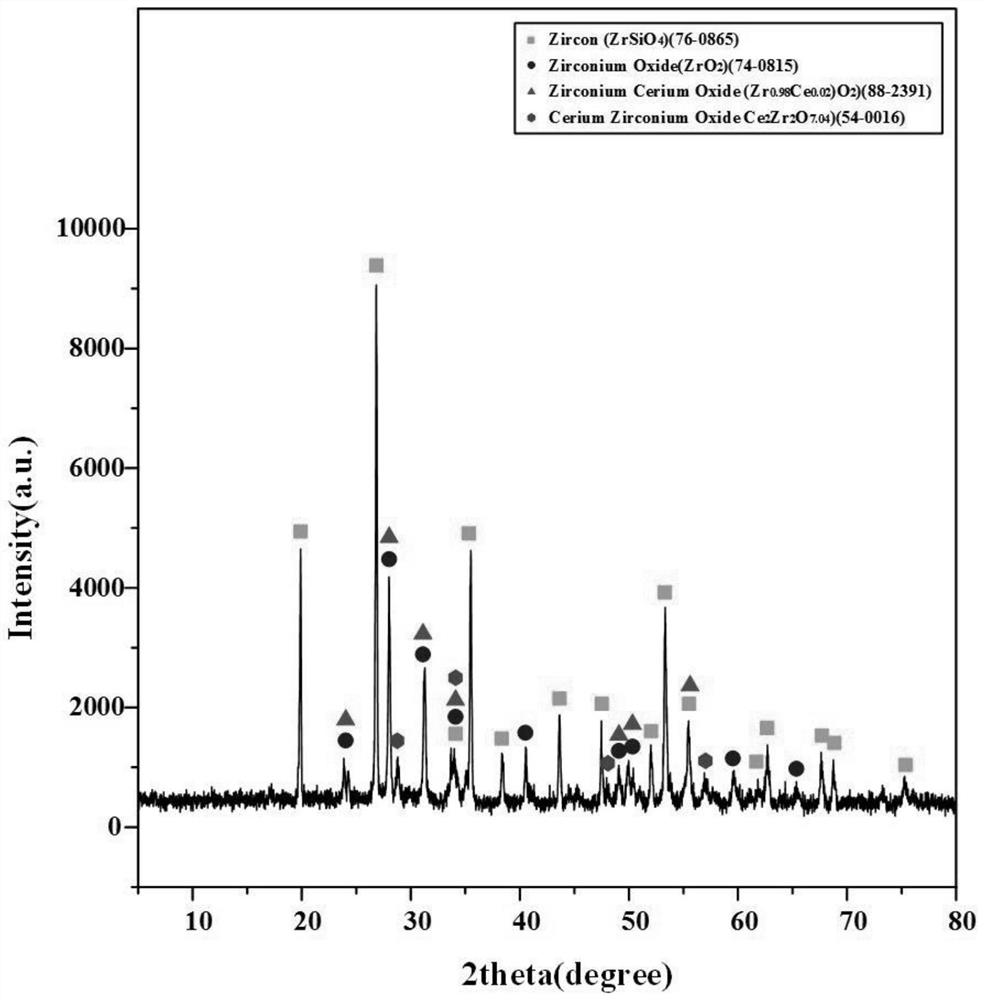

[0033] Step 1. According to the mass ratio of 100:120:6.6:6.6:24.2, add quartz, monoclinic zirconia, praseodymium oxide, cerium oxide and mineralizer (formed by blending sodium fluoride and sodium chloride in any ratio) to the ball mill in sequence In the tank, ball mill for 2 h to mix the materials evenly, then take 10 g of the mixed material and press it into a Ф3 cm disc under a pressure of 40 kN, then put the disc in a crucible with a cover, and cover the crucible Then put it into an electric furnace and calcinate at 1360 °C for 2 hours, cool the calcined product to room temperature, then ball mill it for 2 hours, then wash it with distilled water until it is neutral, filter it with suction, and dry it to obtain the ceramic color material;

[0034] Step 2. Mix the ceramic pigment obtained in step 1 with water and sodium polyacrylate in a mass ratio of 30:60:10 and ball ...

Embodiment 2

[0039] A kind of ink-jet printing water-based yellow ceramic ink, its preparation comprises the steps:

[0040] Step 1. Add quartz, monoclinic zirconia, praseodymium oxide, cerium oxide and mineralizer (potassium fluoride) into the ball mill tank in sequence according to the mass ratio of 100:135:35.25:35.25:28.2, and ball mill for 2 hours to mill the materials Mix evenly, then take 10 g of the mixture obtained by mixing and press it into a Ф3 cm disc under a pressure of 40 kN, then place the disc in a crucible with a cover, cover the crucible and put it in an electric furnace for calcination at 1300 °C After 2 h, cool the calcined product to room temperature and then ball mill it for 4 h, then wash it with distilled water until it is neutral, then filter it with suction and dry it to obtain the ceramic color material;

[0041] Step 2. Mix the ceramic pigment obtained in step 1 with water and polyethylene glycol in a mass ratio of 37:55:8 and ball mill for 2 h to form a suspen...

Embodiment 3

[0045] A kind of ink-jet printing water-based yellow ceramic ink, its preparation comprises the steps:

[0046] Step 1. Add quartz, monoclinic zirconia, praseodymium oxide, cerium oxide and mineralizer (formed by blending sodium sulfate and potassium sulfate in any ratio) into the ball mill tank in sequence according to the mass ratio of 100:150:75:75:32.5 In the process, ball mill for 2 h to mix the materials evenly, then take 10 g of the mixed material and press it into a Ф3 cm disc under a pressure of 40 kN, then put the disc in a crucible with a cover, cover the crucible Put it into an electric furnace and calcinate at 1360 °C for 2 hours, cool the calcined product to room temperature, then ball mill it for 2 hours, then wash it with distilled water until it is neutral, then filter it with suction and dry it to obtain the ceramic color material;

[0047] Step 2, mix the ceramic pigment obtained in step 1 with water and sodium lauryl sulfate in a mass ratio of 40:50:10 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

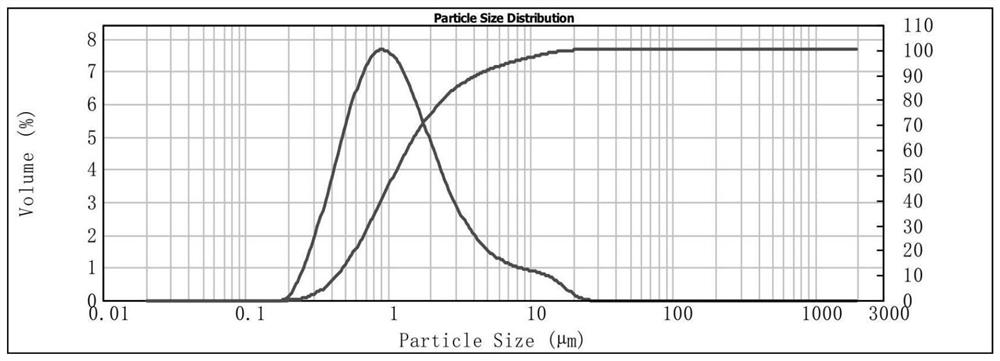

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com