Graded retarded cross-linked emulsified acid and preparation method thereof

A technology of emulsified acid and cross-linked acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the length of cross-linked acid acid-etched cracks and the conductivity cannot meet the needs of deep penetration, and achieve good Effect of acid fracturing/acidification, prospect of widespread application, effect of improving diversion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

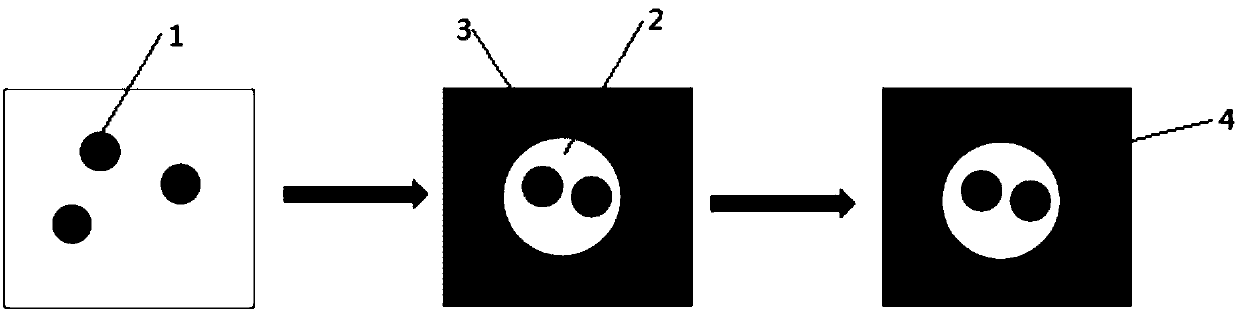

Image

Examples

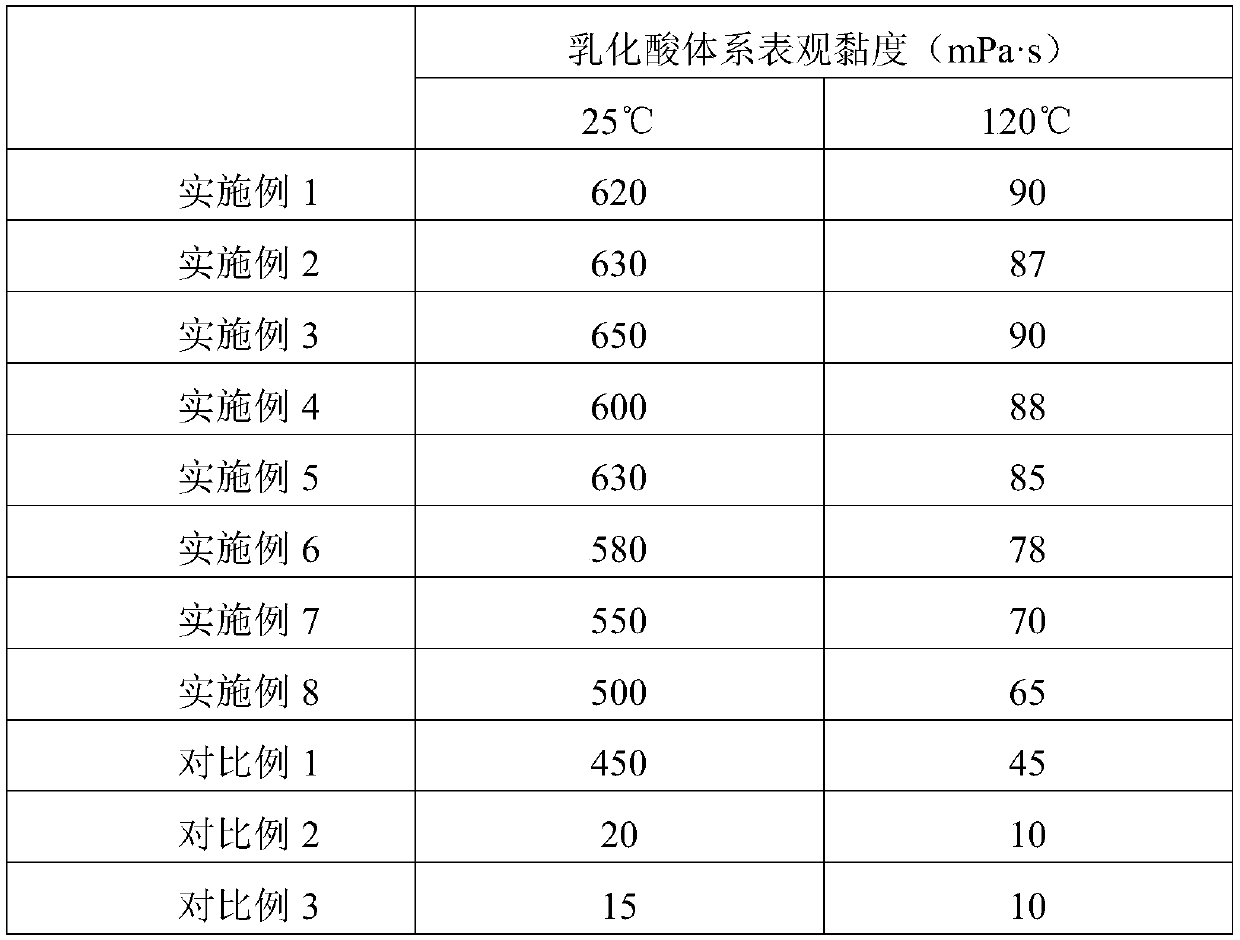

Embodiment 1

[0055] 1) prepare the emulsified acid phase by the following components by weight: get 97.0 parts of 15% hydrochloric acid aqueous solution, under the rotating speed of 500r / min, add 1.0 parts of iron ion stabilizer ethylenediaminetetraacetic acid (Tianjin Guangfu Chemical Reagent Factory) and 2.0 parts of imidazoline corrosion inhibitor, stir evenly;

[0056] 2) The oil phase was prepared according to the following components by weight: 2.0 parts of dipolyhydroxystearate and 0.5 part of hexadecylamine were heated and dissolved in diesel oil, stirred evenly, and cooled to room temperature;

[0057] 3) Prepare the emulsified acid according to the following components by volume: under the condition of stirring speed of 1500r / min, slowly add the prepared acid phase into the oil phase, the volume ratio of the acid phase and the oil phase is 70:30, drop Continue to stir for 20 minutes after adding to obtain emulsified acid system;

[0058] 4) Prepare the cross-linked acid base sol...

Embodiment 2

[0062] 1) Prepare the emulsified acid phase according to the following components by weight: take 96.5 parts of 15% hydrochloric acid aqueous solution, at 500r / min rotating speed, add 1.2 parts of iron ion stabilizer citric acid (commercially available) and 2.3 parts of quinoline quaternary ammonium salt Class corrosion inhibitor (commercially available), stir evenly;

[0063] 2) The oil phase was prepared according to the following components by weight: 2.0 parts of sorbitan sesquioleate and 0.5 parts of polyoxyethylene octylphenol ether-10 were heated and dissolved in diesel oil, stirred evenly, and cooled to room temperature;

[0064] 3) Prepare the emulsified acid according to the following components by volume: under the condition of stirring speed of 2000r / min, slowly add the prepared acid phase into the oil phase, the volume ratio of the acid phase and the oil phase is 65:35, drop Continue to stir for 15 minutes after adding to obtain emulsified acid system;

[0065] 4...

Embodiment 3

[0069] 1) Prepare the emulsified acid phase according to the following components by weight: Take 96.0 parts of 20% hydrochloric acid aqueous solution, at 500r / min rotating speed, add 1.5 parts of iron ion stabilizer acetic acid and citric acid 1:1 mixture (commercially available) and 2.5 parts Paraformaldehyde / p-aniline / acetophenone corrosion inhibitor (commercially available), stirred evenly;

[0070] 2) The oil phase was prepared according to the following components by weight: 2.0 parts of sorbitan fatty acid ester and 0.5 part of polyoxyethylene octylphenol ether-10 were heated and dissolved in diesel oil, stirred evenly, and cooled to room temperature;

[0071] 3) Prepare the emulsified acid according to the following components by volume: under the condition of stirring speed of 2500r / min, slowly add the prepared acid phase into the oil phase, the volume ratio of the acid phase and the oil phase is 60:40, drop Continue to stir for 10 minutes after the addition to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com