Hollow-core anti-resonance optical fiber with core shift structure

An eccentric structure, anti-resonance technology, applied in the direction of multi-layer core/clad fiber, clad fiber, light guide, etc., can solve the problem of not being able to ensure low bending loss and quasi-single-mode transmission at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

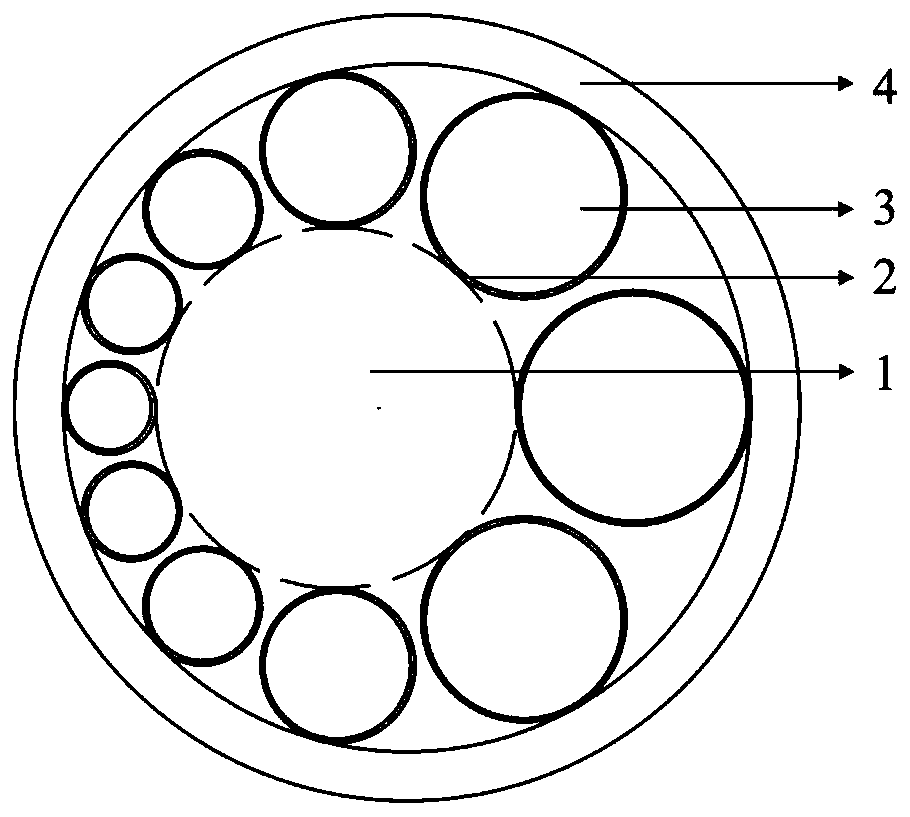

[0033] Such as figure 1 As shown, a cladding graded eccentric hollow-core antiresonant fiber with 12 thin-walled tubes is shown, in which the ratio of the largest thin-walled ring diameter to the core is 0.65, and the ratio of the smallest thin-walled ring diameter to the core diameter is 0.3. Each thin-walled tube is separated by a distance of 6 wall thicknesses. The core circle is tangent to all thin-walled tubes.

[0034] In this embodiment, the core region may be liquid, gas or vacuum.

[0035] In this embodiment, the high refractive index thin-walled tube and the outer cladding are silicon dioxide, doped glass, photosensitive resin or plastic.

Embodiment 2

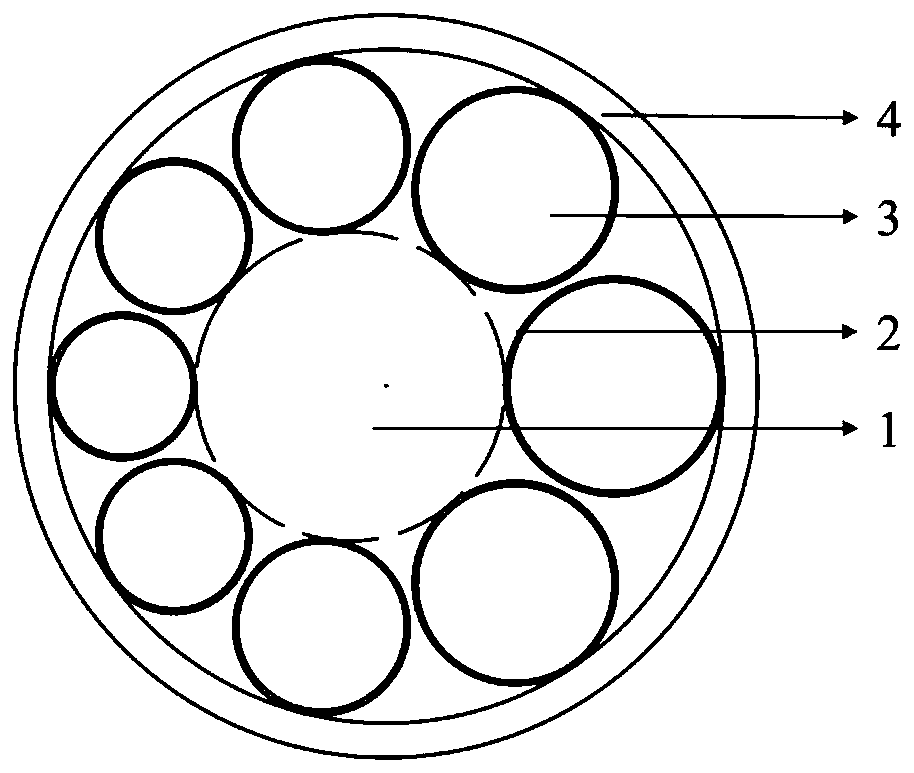

[0037] Such as figure 2 As shown, a graded cladding eccentric hollow-core antiresonant fiber with 8 thin-walled tubes is shown, in which the ratio of the largest thin-walled ring diameter to the fiber core is 0.7, and the ratio of the smallest thin-walled ring diameter to the fiber core diameter is 0.45. Each thin-walled tube is separated by a distance of 5 wall thicknesses. The core circle is tangent to all thin-walled tubes.

[0038] In this embodiment, the core region may be liquid, gas or vacuum.

[0039]In this embodiment, the high refractive index thin-walled tube and the outer cladding are silicon dioxide, doped glass, photosensitive resin or plastic.

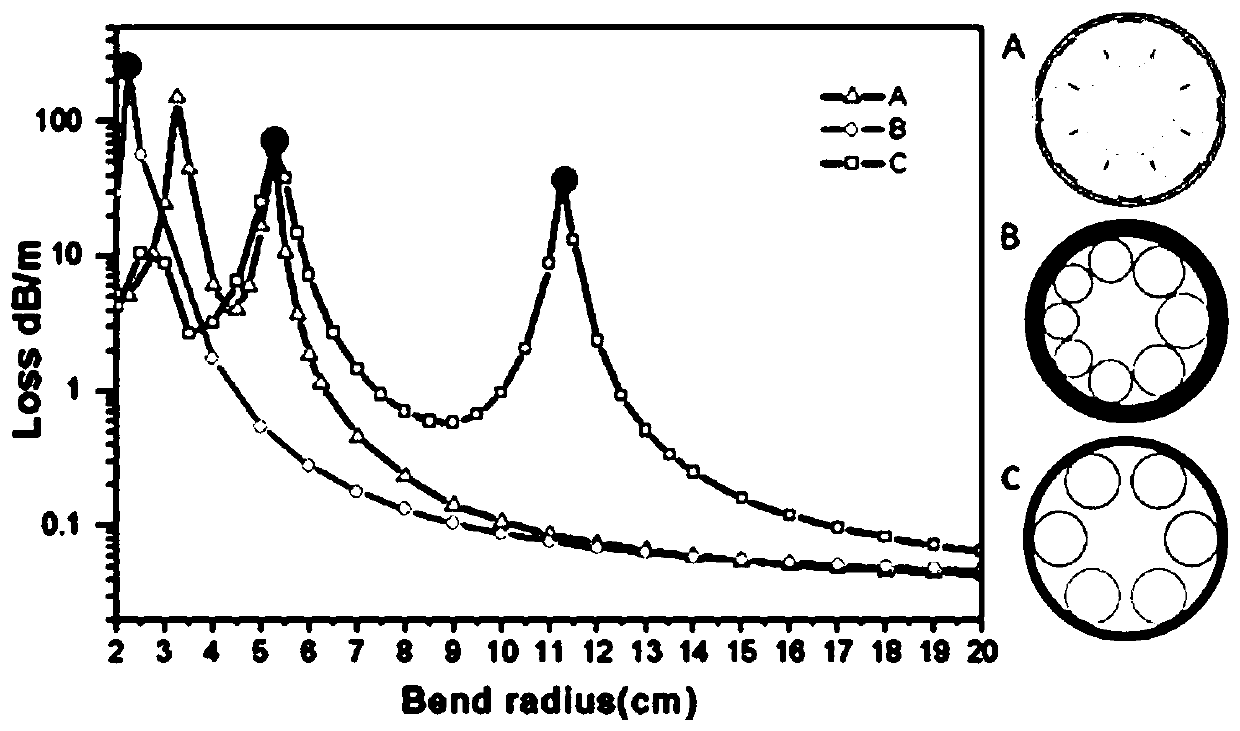

[0040] Such as image 3 As shown, the figure shows the second embodiment of the present invention-the cladding graded eccentric hollow-core anti-resonant fiber of 8 thin-walled tubes and the traditional symmetrical 8-thin-walled tube and 6-thin-walled tube hollow-core anti-resonant fiber bent Simulation comparison d...

Embodiment 3

[0042] Such as Figure 4 As shown in , a schematic diagram of the structure of the end face of the resonant layer asymmetric eccentric hollow-core anti-resonant fiber is shown. The inner cladding is composed of 6 thin-walled rings with the same diameter, and a resonant layer 5 is added on the side with larger stress along the bending direction, and the thickness difference between the resonant layer and the thin-walled rings is no more than 40%. The resonant layer can consist of nested tubes and connecting tubes.

[0043] In this embodiment, the core region may be liquid, gas or vacuum.

[0044] In this embodiment, the high refractive index thin-walled tube and the outer cladding are silicon dioxide, doped glass, photosensitive resin or plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com