Yellowing-resistant polyamide resin and preparation method thereof

A polyamide resin and polyamide technology, applied in the field of polyamide resin with anti-yellowing effect and its preparation, can solve problems such as yellowing, weak stability, and easy yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

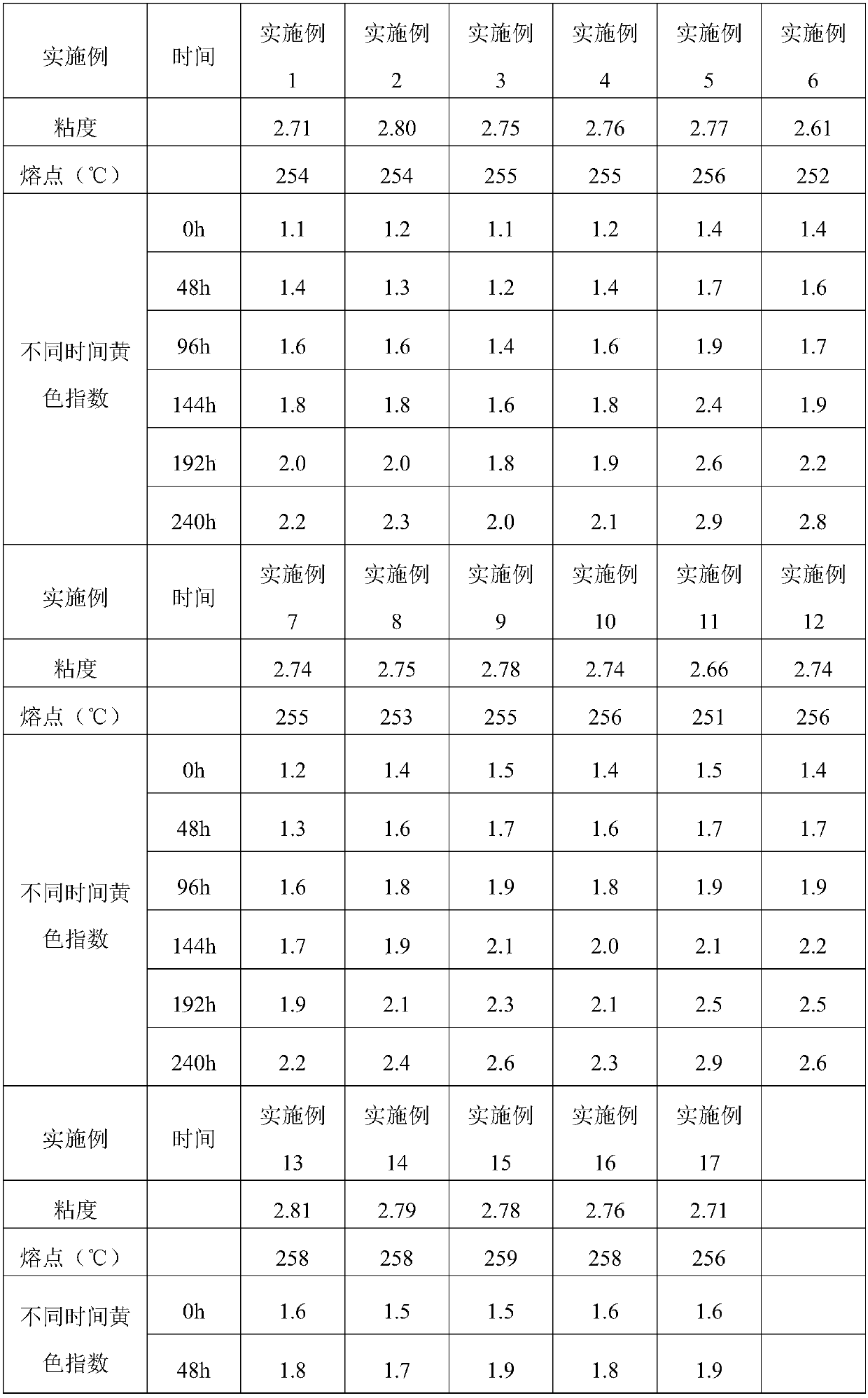

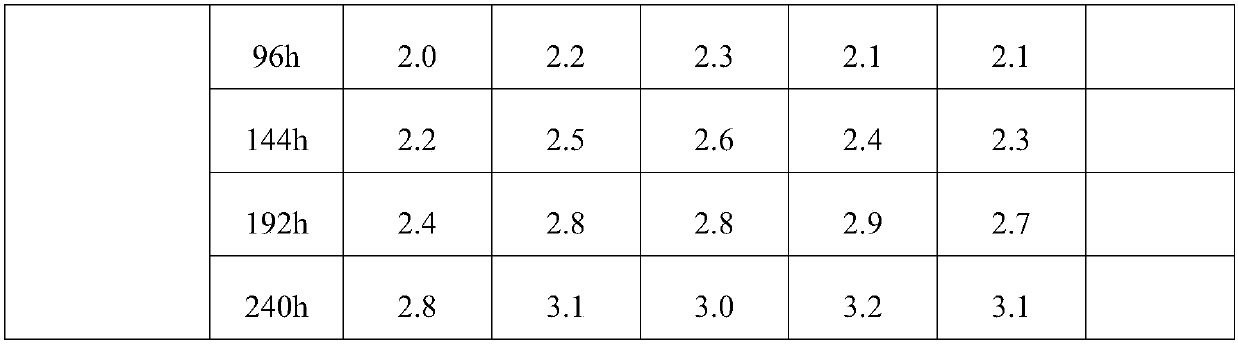

Examples

Embodiment 1

[0065] The preparation of embodiment 1 polyamide 56

[0066] Deoxygenate the pure water by ultrasound, that is, add 1L of pure water into a 2L flask, and place the flask in an ultrasonic device that is filled with water. The water level of the ultrasonic device exceeds the water level in the flask. First turn on the ultrasound with a frequency of 35kHz, then evacuate the inside of the device to vacuum, and keep it for 3-5 minutes, then fill it with nitrogen to normal pressure, then repeat the pumping and inflation 3-5 times, and then fill it with nitrogen to return to normal pressure. Insert a long needle below the water surface to blow nitrogen gas at a flow rate of 30mL / min, and export nitrogen gas through another needle above the water surface, keep the nitrogen gas flowing for 1 hour with the ultrasound turned on, turn off the ultrasound and stop the nitrogen gas flow, and seal it for storage. Take this deoxygenated water sample through a needle tube to measure the oxygen ...

Embodiment 2

[0074] The preparation of embodiment 2 polyamide 56

[0075]1 L of deoxygenated water was prepared using the same method as in Example 1, and the oxygen content was determined to be 0.04 mg / L. Then the adipic acid of 600g, 0.026g sodium hypophosphite (25ppm, the percentage is the mass percent of pentamethylenediamine-adipate) and 0.031g anhydrous copper acetate (30ppm, the percentage is the mass percent of pentamethylenediamine-hexane The mass percent of the diacid acid salt) is added to the batching container, and after repeated pumping and nitrogen filling for 3 times, the normal pressure is restored. Deoxygenated water is then introduced into the batching container, followed by adding 440g of pentamethylenediamine through a conduit, stirred and dissolved, and prepared into a polyamide salt solution, wherein pentamethylenediamine-adipate accounts for 50% of the total weight of the polyamide salt solution. A small amount of the above solution was diluted to 10% and the pH va...

Embodiment 3

[0082] The preparation of embodiment 3 polyamide 56

[0083] A thermal atmospheric deaerator (purchased from Lianyungang Guanghe Electric Power Equipment Co., Ltd., the model is an atmospheric vacuum deaerator) was used to deoxygenate the pure water to obtain deoxygenated water. Deoxygenated water is sent to the reaction unit through the boiler feed water pump. During the deaeration process, the working steam pressure of the equipment is 0.02MPa, the internal pressure of the deaerator is 0.2MPa, the water temperature is 104°C, and the contact time between steam and water is 17min.

[0084] With 500kg pentamethylenediamine-adipic acid crystalline salt, 12.5g sodium hypophosphite (25ppm, percentage is accounted for the mass percentage of pentamethylenediamine-adipate) and 15.0g copper acetate (30ppm, percent is accounted for pentamethylenediamine -mass percentage of adipate) was added to the batching container, and after repeated pumping and nitrogen filling for 3 times, the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com