Composite blocking remover for water injection well

A composite plug-removing agent and a technology for water injection wells, which are applied in the directions of drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

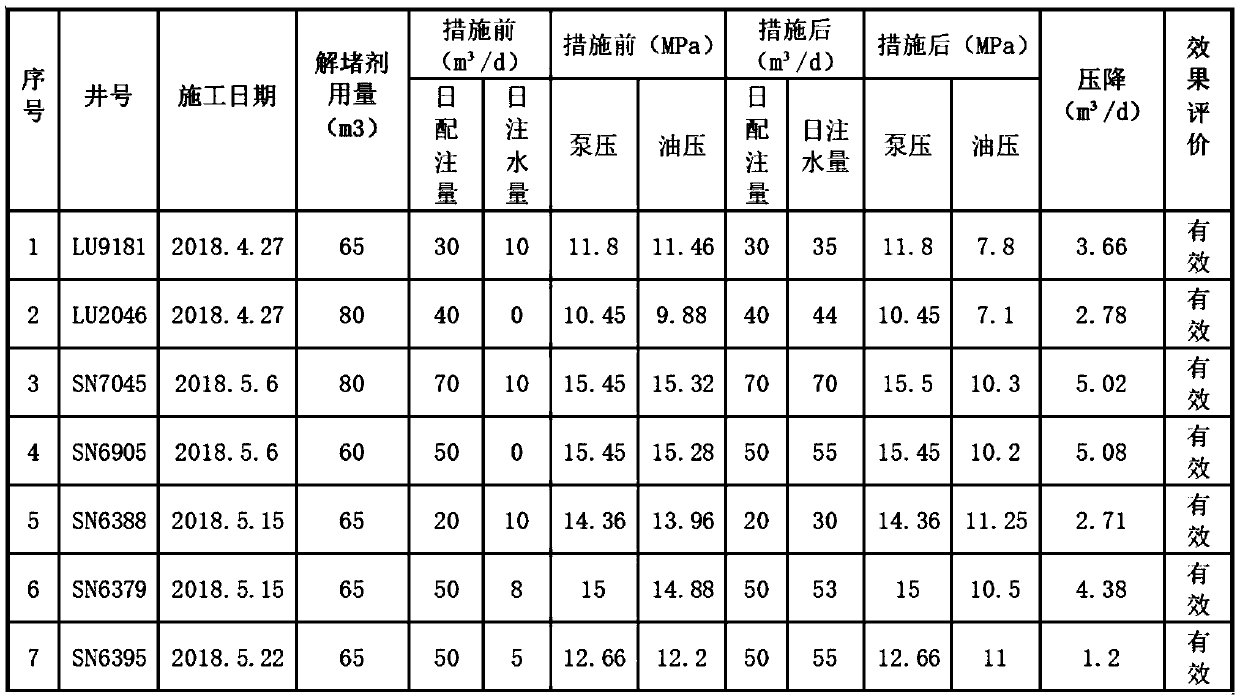

Examples

Embodiment 1

[0026] A composite plugging removal agent for water injection wells, comprising the following components in parts by weight: 0.5 parts of ZYF-1 anti-swelling agent, 1 part of potassium chloride, 2 parts of fluorocarbon surfactant, 2 parts of alkylphenol polyoxyethylene ether, polyoxyethylene 5 parts of vinyl alcohol, 3 parts of citric acid, 3 parts of malic acid, 3 parts of oxalic acid, 3 parts of sodium edetate, 2 parts of sodium diethylenetriamine pentacarboxylate, 15 parts of sodium hypochlorite solution, 60.5 parts of water.

[0027] The preparation method comprises the following steps: firstly, adding fluorocarbon surfactant, alkylphenol polyoxyethylene ether, polyvinyl alcohol, sodium edetate and sodium diethylenetriaminepentacarboxylate into the enamel reaction kettle in proportion , slowly heat up to 75-80°C; secondly, add 10% water under continuous stirring, continue stirring for 30 minutes, then slowly cool down to 50-55°C, and then add citric acid, malic acid, oxalic...

Embodiment 2

[0029] A composite plugging removal agent for water injection wells, comprising the following components in parts by weight: 2.5 parts of ZYF-1 anti-swelling agent, 3 parts of ammonium chloride, 1 part of fluorocarbon surfactant, 1 part of alkylphenol polyoxyethylene ether, polyoxyethylene 1 part of vinyl alcohol, 2 parts of citric acid, 4 parts of malic acid, 2 parts of oxalic acid, 6 parts of sodium edetate, 2 parts of sodium diethylenetriamine pentacarboxylate, 25 parts of sodium hypochlorite solution, 50.5 parts of water.

[0030] Its preparation method includes the following steps: first, add fluorocarbon surfactant, alkylphenol polyoxyethylene ether, polyvinyl alcohol, sodium edetate and sodium diethylenetriaminepentacarboxylate into the enamel reaction kettle in proportion , slowly raise the temperature to 75-80°C; secondly, add 10% water under continuous stirring, continue stirring for 30 minutes, then slowly cool down to 50-55°C, and then add citric acid, malic acid, o...

Embodiment 3

[0032] A composite plugging removal agent for water injection wells, comprising the following components in parts by weight: 2 parts of ZYF-1 anti-swelling agent, 2 parts of ammonium chloride, 1 part of fluorocarbon surfactant, 1 part of alkylphenol polyoxyethylene ether, polyoxyethylene 3 parts of vinyl alcohol, 2 parts of citric acid, 4 parts of malic acid, 2 parts of oxalic acid, 6 parts of sodium edetate, 2 parts of sodium diethylenetriamine pentacarboxylate, 20 parts of sodium hypochlorite solution, 55 parts of water.

[0033] Its preparation method includes the following steps: first, add fluorocarbon surfactant, alkylphenol polyoxyethylene ether, polyvinyl alcohol, sodium edetate and sodium diethylenetriaminepentacarboxylate into the enamel reaction kettle in proportion , slowly raise the temperature to 75-80°C; secondly, add 10% water under continuous stirring, continue stirring for 30 minutes, then slowly cool down to 50-55°C, and then add citric acid, malic acid, oxal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com