Furnace top feeding device of oxygen-enriched double-side-blown molten pool copper smelting furnace

A feeding device, copper furnace technology, applied in the direction of charge, furnace, crucible furnace, etc., can solve the problems of increased resistance, high grade copper fume, and reduced dust collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention will be further described.

[0016] The present invention can be applied to a copper smelting pool copper smelting furnace with a single feeding port with an ore feeding rate of 50-55t / h. If multiple feeding ports are used for production, the feeding device can be directly added.

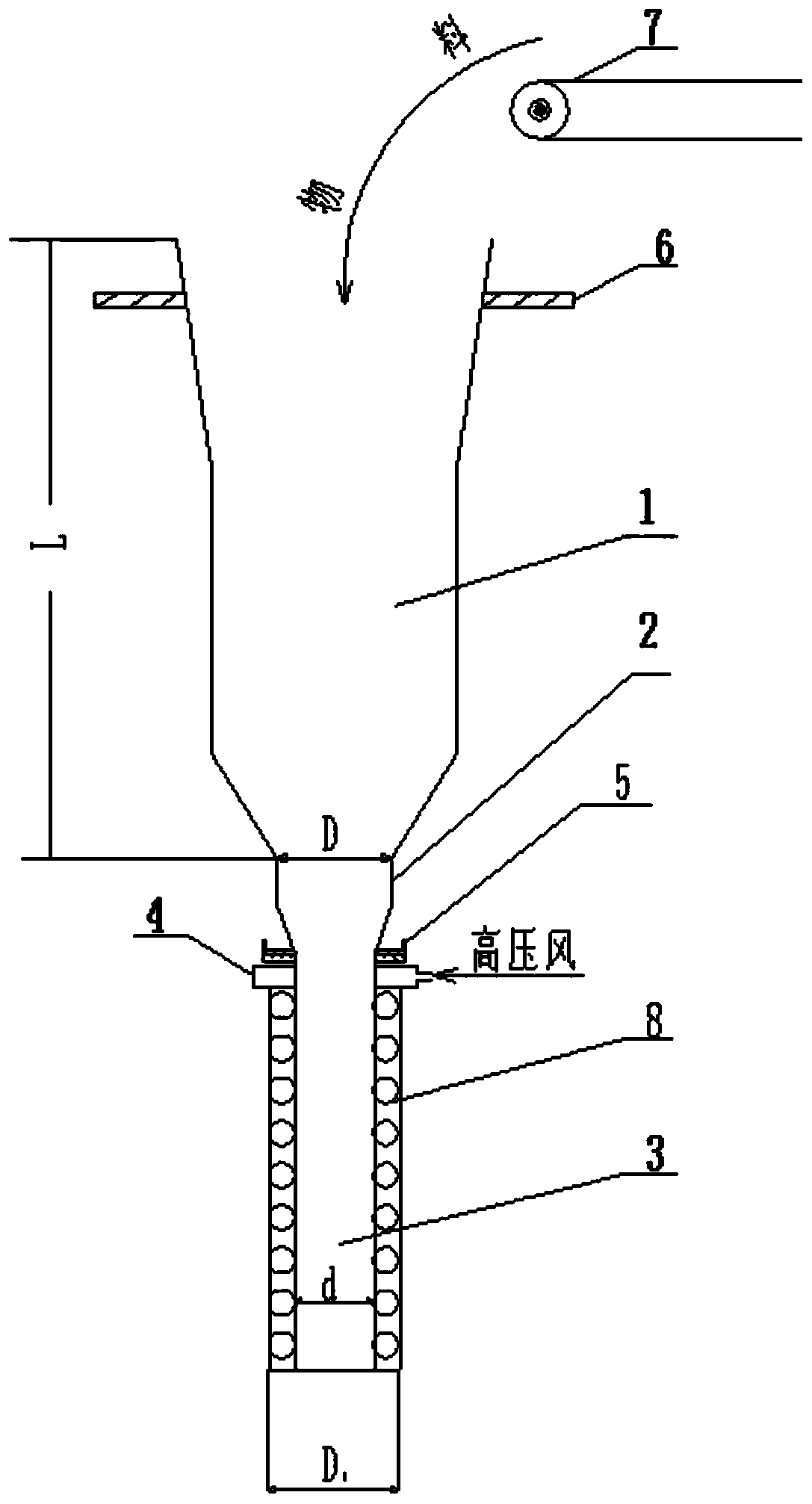

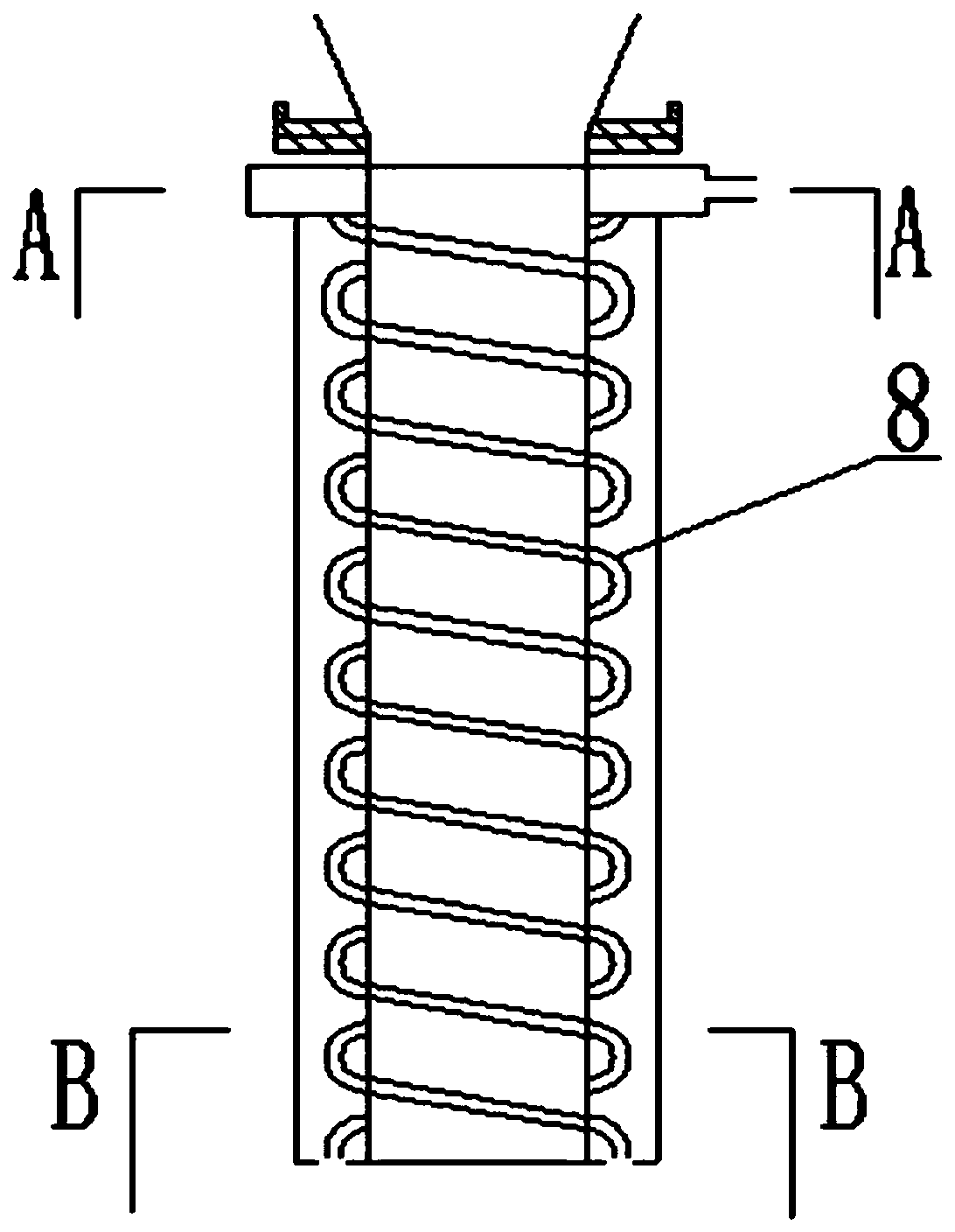

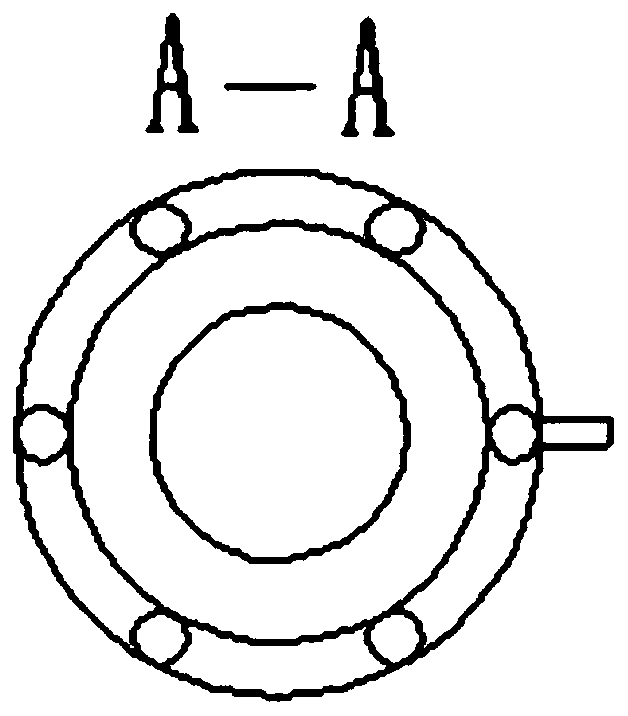

[0017] Depend on figure 1 It can be seen that the furnace top charging device disclosed in the present invention is composed of four parts, the middle of which is connected by welding or flanges. The material collecting and expanding container 1 in the device is connected with the discharging and draining pipe 2 by welding, and is fixed above the feeding port of the furnace roof through a support rod, and is located between the belt conveyors. Set the pressure equalizing ring casing 4 on the outside of the feeding extension pipe 3, and extend its lower end to 1.5 meters into the furnace. The copper concentrate and auxiliary materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com