Novel lithium-ferrous chloride battery based on garnet solid electrolyte and preparation method thereof

A solid electrolyte, ferrous chloride technology, used in inorganic electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve problems such as ceramic tube corrosion, achieve good conductive paths, high-quality energy density and volume energy density, good Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

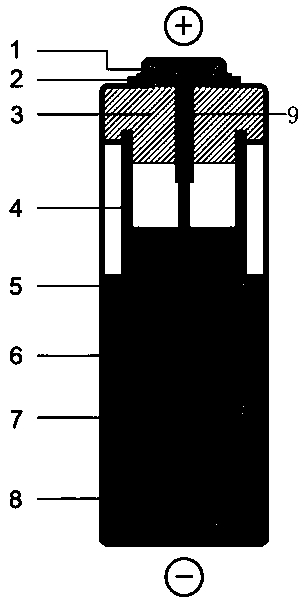

Method used

Image

Examples

Embodiment 1

[0030] S1, LiCl and AlCl with a content of 99.9% 3 Mix well in the glove box, then transfer the mixture to an aluminum container, put it in the muffle furnace in the glove box, heat up to 100°C within 20 minutes, then keep at 100°C for 4 hours; then heat up to 160C within 20 minutes , kept at 160°C for 6 hours, and finally raised to 200°C within 20 minutes, and kept at 200°C for 3 hours to make LiAlCl 4 Secondary electrolyte for backup;

[0031] S2. Weigh LiI and CsI with a mass ratio of 1:0.9 in the glove box and mix them in a glass bottle, transfer to the muffle furnace in the glove box and heat to 300°C, keep it warm for 1 hour, after the sample is completely melted, use a stainless steel rod Skim off the upper layer of foam, then pour the melt onto stainless steel foil, grind it into powder after solidification, and make LiI-CsI mixture for later use;

[0032] S3. Preparation of lead-sealed shell: Fill the stainless steel shell with lead grains, place it in the muffle fu...

Embodiment 2

[0035] S1, LiCl and AlCl with a content of 99.9% 3 Mix well in the glove box, then transfer the mixture to an aluminum container, put it in the muffle furnace in the glove box, heat up to 100°C within 20 minutes, then keep at 100°C for 4 hours; then heat up to 160C within 20 minutes , kept at 160°C for 6 hours, and finally raised to 200°C within 20 minutes, and kept at 200°C for 3 hours to make LiAlCl 4 Secondary electrolyte for backup;

[0036] S2. Weigh LiI and CsI with a mass ratio of 1:0.98 in the glove box and mix them in a glass bottle, transfer to the muffle furnace in the glove box and heat to 300°C, keep it warm for 1 h. After the sample is completely melted, use a stainless steel rod Skim off the upper layer of foam, then pour the melt onto stainless steel foil, grind it into powder after solidification, and make LiI-CsI mixture for later use;

[0037] S3. Preparation of lead-sealed shell: Fill the stainless steel shell with lead grains, place it in the muffle furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com