Preparation method of low-mutton-smell fermented dried mutton slices

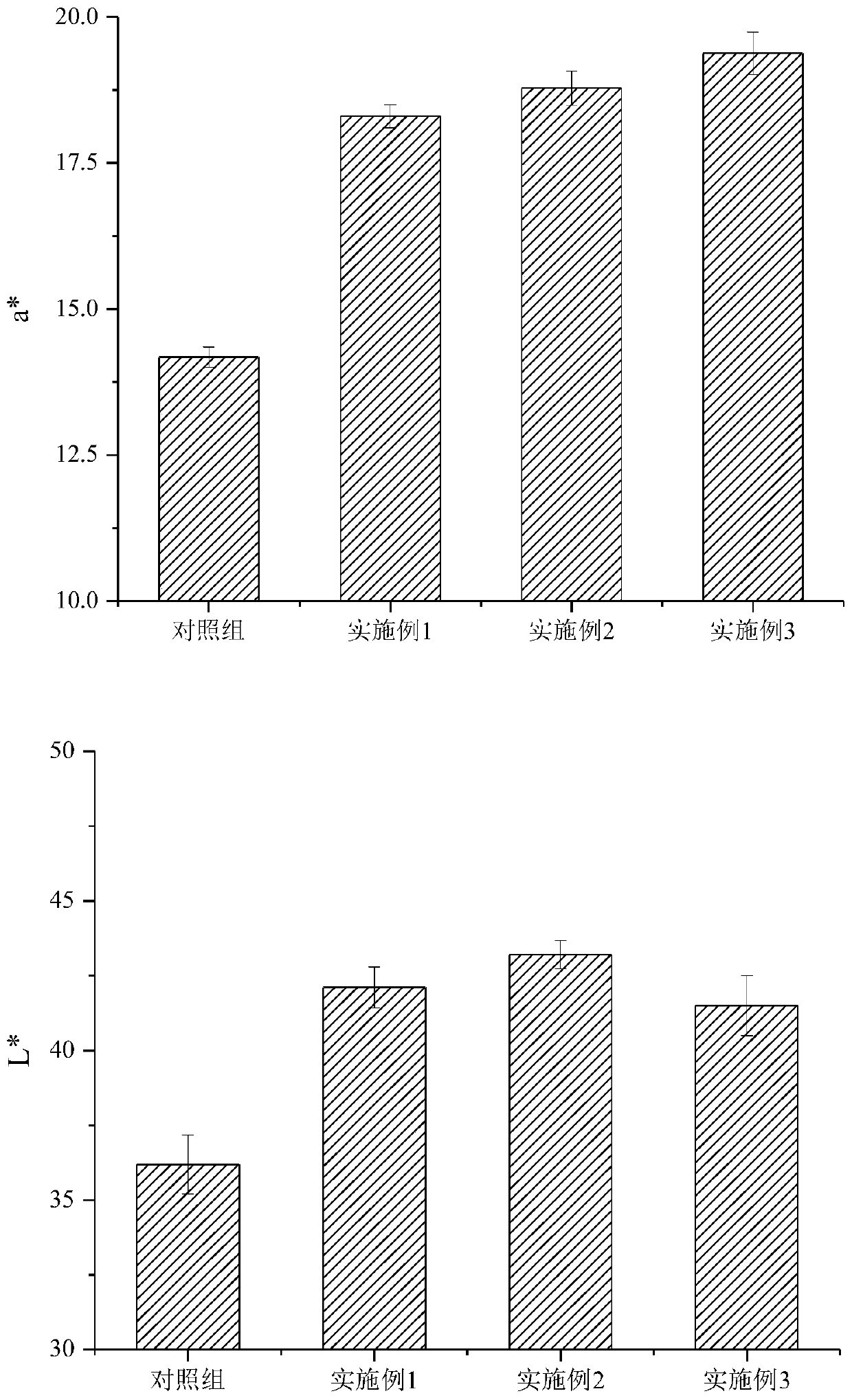

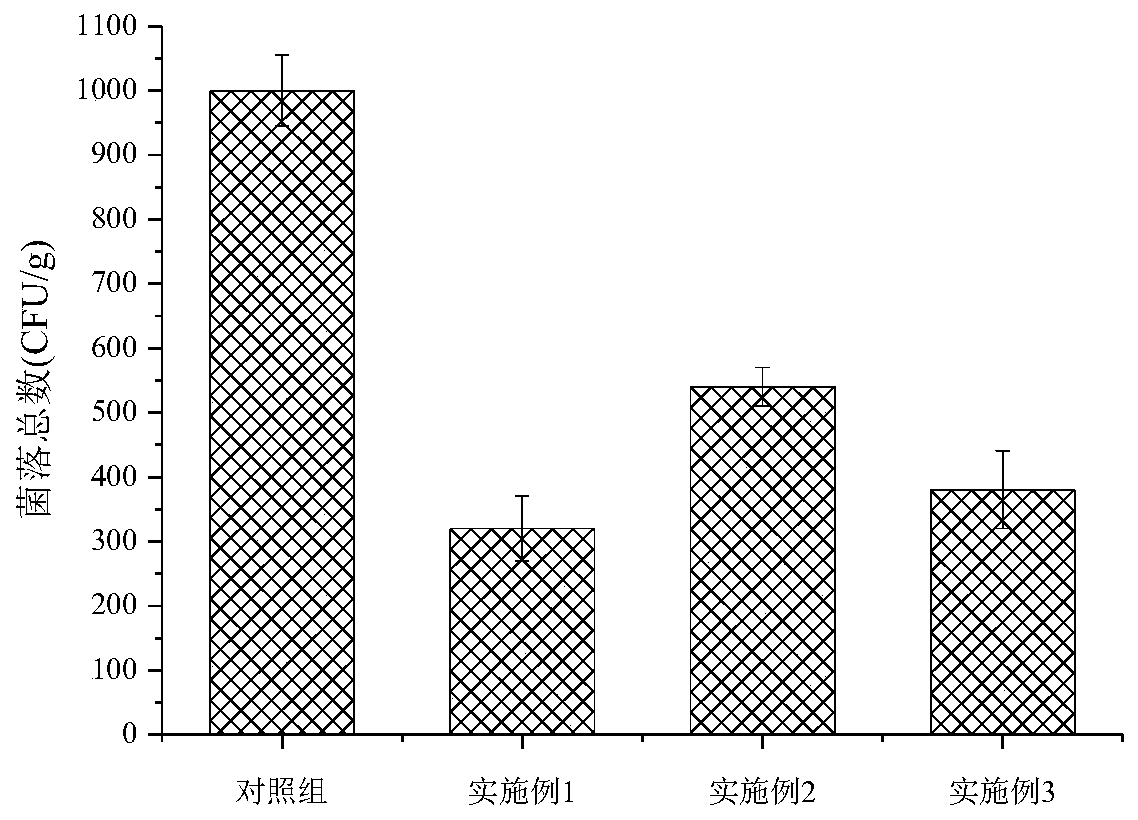

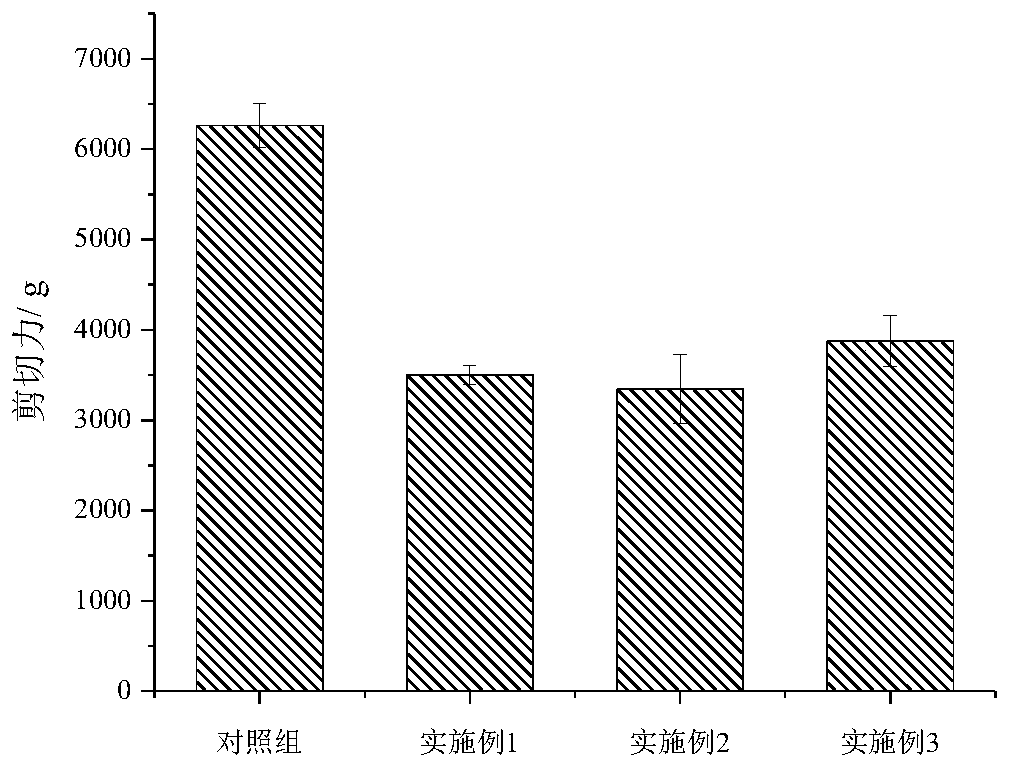

A production method and mutton technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, and the functions of food ingredients, can solve the problems of not meeting the requirements for the preparation of low-smelling fermented dried mutton, and achieve stable color and low smell , crispy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, a kind of preparation method of low-smelly fermented mutton jerky, carries out following steps successively:

[0050] (1) Cleaning and pretreatment of raw materials: Remove the blood clots, visible fat, tendon and connective tissue from the fresh lamb hind legs, wash in water at 4-10°C and drain (until there is no more dripping water).

[0051] (2) Freezing: Freeze the mutton at -20°C for 24 hours to obtain frozen mutton.

[0052] (3) Slicing: Cut the frozen mutton into thin slices with a thickness of 5 mm along the muscle fiber direction, and thaw at room temperature (that is, the surface temperature of the mutton slices is the same as room temperature) to obtain mutton slices.

[0053] (4) Pickling: Weigh 1000g of mutton slices, and add the following ingredients according to 100 parts of the total meat: 10 parts of white sugar, 2 parts of salt, 0.2 parts of monosodium glutamate, 0.1 part of pepper powder, 3 parts of soy sauce, 2 parts of cooking wine, fi...

Embodiment 2

[0068] Embodiment 2, a kind of preparation method of low-smelly fermented mutton jerky, carries out following steps successively:

[0069] (1) Cleaning and pretreatment of raw materials: Remove blood clots, visible fat, tendon and connective tissue from fresh lamb hind legs, wash in water at 4-10°C, and drain.

[0070] (2) Freezing: Freeze the mutton at -10°C for 36 hours to obtain frozen mutton.

[0071] (3) Slicing: Cut the frozen mutton into thin slices with a thickness of 5 mm along the muscle fiber direction, and thaw at room temperature to obtain mutton slices.

[0072] (4) Pickling: Weigh 1000g of mutton slices, and add the following ingredients according to the total meat amount of 100 parts: 15 parts of white sugar, 1 part of salt, 0.15 parts of monosodium glutamate, 0.15 parts of pepper powder, 2 parts of soy sauce, 2 parts of cooking wine, five spices 0.1 portion of powder, and then marinated at 4°C for 10 hours; marinated mutton slices were obtained.

[0073] (5)...

Embodiment 3

[0082] Embodiment 3, a kind of preparation method of low-smelly fermented dried mutton, carries out following steps successively:

[0083] (1) Cleaning and pretreatment of raw materials: Remove blood clots, visible fat, tendon and connective tissue from fresh lamb hind legs, wash in water at 4-10°C, and drain.

[0084] (2) Freezing: Freeze the mutton at -15°C for 36 hours to obtain frozen mutton.

[0085] (3) Slicing: cut the mutton into thin slices with a thickness of 5 mm along the muscle fiber direction, and thaw at room temperature to obtain mutton slices.

[0086] (4) Pickling: Weigh 1000g of mutton slices, and add the following ingredients according to 100 parts of the total meat: 12 parts of white sugar, 2 parts of salt, 0.3 part of monosodium glutamate, 0.1 part of pepper powder, 3 parts of soy sauce, 1 part of cooking wine, five spices 0.2 portion of powder, and then marinated at 2°C for 12 hours; marinated mutton slices were obtained.

[0087] (5) Preparation of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com