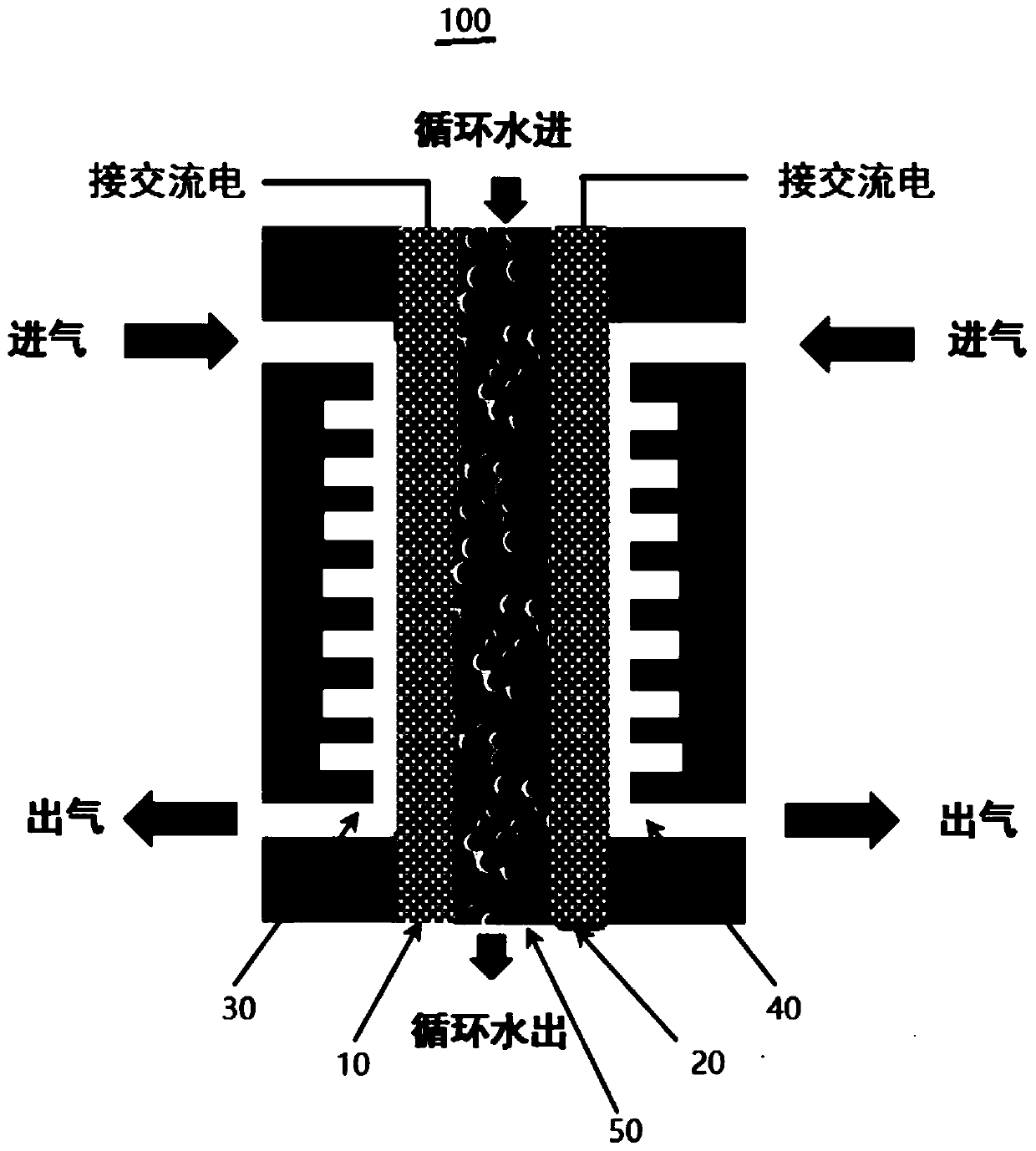

Device and method for degrading gaseous pollutants by electrochemical method

An electrochemical and pollutant technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems that the electrochemical method is not suitable for degradation of water solubility and low degradation efficiency of gaseous pollutants, and achieves high degradation efficiency, Efficient degradation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

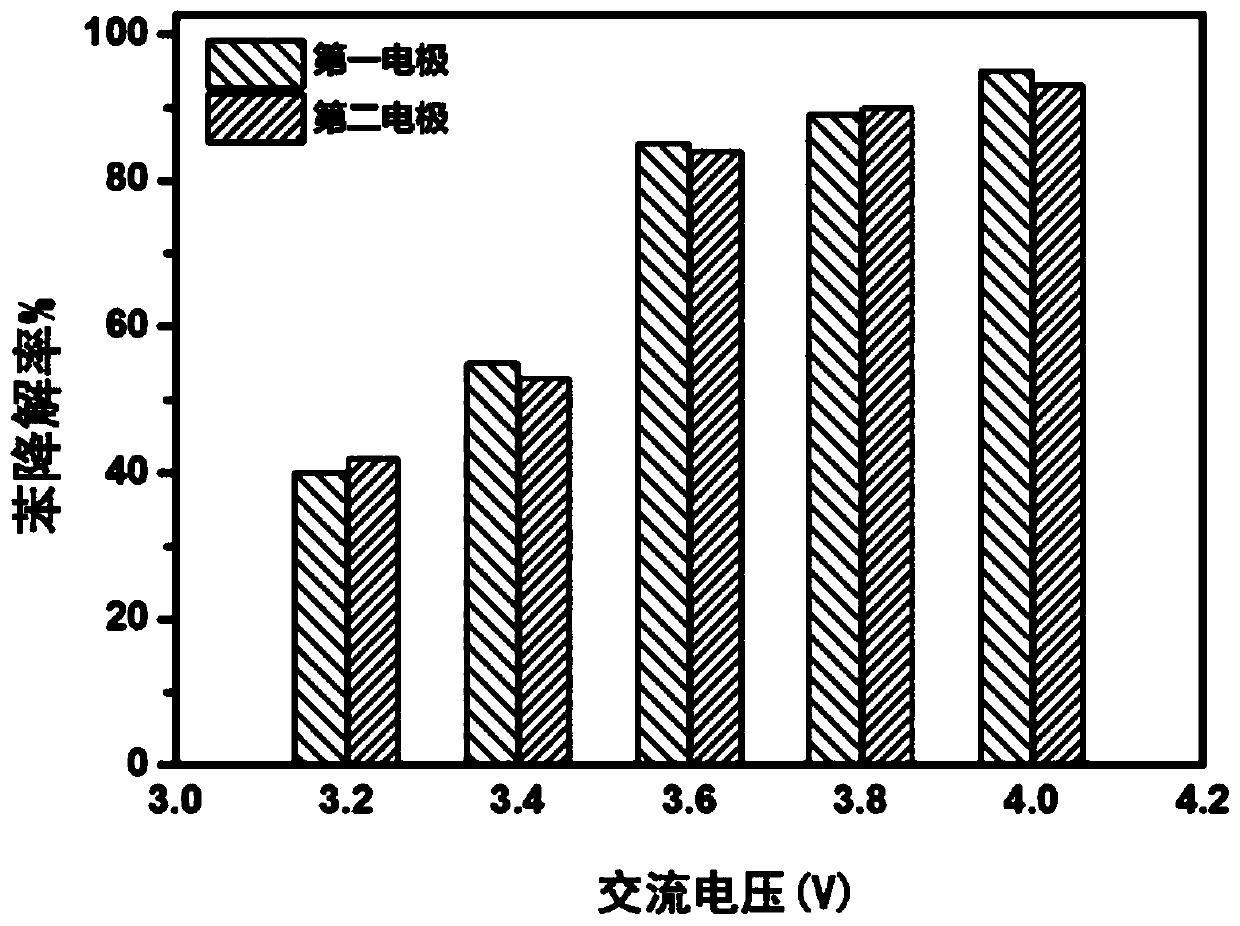

Embodiment 1

[0050] (1) Preparation of the first electrode: ultrasonically disperse 1 g of carbon black in 100 ml of ethanol solvent, add 0.05 g of tin dichloroacetylacetonate, continue ultrasonically dispersing for 2 hours, then stir the dispersion at room temperature for 20 hours, then The carbon black was separated by centrifugation and dried at 50°C. Then, the material was calcined at 450° C. for 1 hour in an air atmosphere to obtain a catalyst with carbon black as a carrier and loaded with tin oxide nanoparticles, that is, a supported tin oxide catalyst. Ultrasonic dispersion of 10 mg of the above-prepared supported tin oxide catalyst into 5 mL of a mixed solution of perfluorosulfonic acid-polytetrafluoroethylene copolymer and isopropanol, and then spraying the dispersion on the surface of a 16 cm2 carbon cloth electrode, can Prepare the first electrode.

[0051] (2) Preparation of the second electrode: The second electrode was prepared according to the above-mentioned method for pre...

Embodiment 2

[0056] (1) Preparation of the first electrode: ultrasonically disperse 1 g of carbon nanotubes in an isopropanol solution containing 10 mmol / L bis(acetylacetonate) diisopropyl titanate, take it out after 2 hours, and put the dispersion in Drying under vacuum at 50°C, and then putting it into a tube furnace and treating it at a high temperature of 400°C under the condition of Ar gas, a catalyst with carbon black as a carrier and loaded with titanium oxide nanoparticles can be obtained, which is a supported titanium oxide catalyst. Ultrasonic dispersion of 10 mg of the above-prepared supported titanium oxide catalyst into 5 mL of a mixed solution of perfluorosulfonic acid-polytetrafluoroethylene copolymer and isopropanol, and then spraying the dispersion on the surface of a 16 square centimeter carbon cloth electrode, can Prepare the first electrode.

[0057] (2) Preparation of the second electrode: The second electrode was prepared according to the above-mentioned method for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com