Nano cage-shaped LiVPO4F battery material and preparation method thereof

A battery material and nano-cage technology, applied in the field of nano-cage LiVPO4F battery material and its preparation, can solve the problems of low electrical conductivity, restricted specific capacity, rate performance and cycle stability, limited modification effect, etc., and achieve high electrical conductivity. , stable and reliable cycle performance, high energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

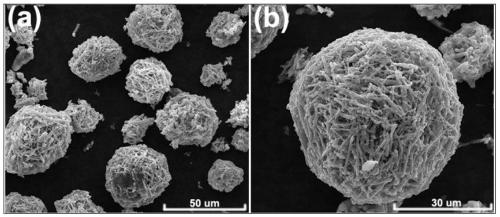

[0031] A kind of nano-cage LiVPO of the present embodiment 4 F battery material, its morphology structure is:

[0032] nano cage

[0033] A kind of nano-cage LiVPO of the present embodiment 4 The preparation method of F battery material, comprises the following steps:

[0034] 1. Mix the vanadium source, phosphorus source and additive A according to the molar ratio of 1:1:0.8, sand mill at 300rpm for 2 hours, adjust the mass concentration to 25% with water, and carry out spray drying treatment at a temperature of 100°C and a pressure of 40Mpa.

[0035] 2. The obtained powder was sintered in a protective atmosphere at 750°C for 4 hours.

[0036] 3. Add lithium source, fluorine source and additive B to the product of step 2 according to the molar ratio of 1:1:1:0.25, mix evenly, and dry.

[0037] 4. Sinter in a protective atmosphere at 700°C for 0.5h, pulverize and grind to obtain the target material powder LiVPO 4 F.

[0038] The vanadium source is NH 4 VO 3 and VOF 3 ...

Embodiment 2

[0047] A kind of nano-cage LiVPO of the present embodiment 4 F battery material, its morphology structure is:

[0048] nano cage

[0049] A kind of nano-cage LiVPO of the present embodiment 4 The preparation method of F battery material, comprises the following steps:

[0050] 1. Mix the vanadium source, phosphorus source and additive A according to the molar ratio of 1:1:0.5, sand mill at 200rpm for 3h, adjust the mass concentration to 30% with water, carry out spray drying treatment at a temperature of 80°C and a pressure of 50Mpa.

[0051] 2. The obtained powder was sintered in a protective atmosphere at 750°C for 2 hours.

[0052] 3. Add lithium source, fluorine source and additive B to the product of step 2 according to the molar ratio of 1:1.2:1:0.2, mix evenly, and dry.

[0053] 4. Sinter in a protective atmosphere at 650°C for 1h, crush and grind to obtain the target material powder LiVPO 4 F.

[0054] The vanadium source is V 2 o 5 .

[0055] The phosphorus s...

Embodiment 3

[0064] A kind of nano-cage LiVPO of the present embodiment 4 F battery material, its morphology structure is:

[0065] Nano ball cage shape.

[0066] A kind of nano-cage LiVPO of the present embodiment 4 The preparation method of F battery material, comprises the following steps:

[0067] 1. Mix the vanadium source, phosphorus source and additive A according to the molar ratio of 0.98:0.99:1, sand mill at 300rpm for 1.5h, adjust the mass concentration to 35% with water, carry out spray drying treatment at a temperature of 120°C and a pressure of 30Mpa.

[0068] 2. The obtained powder was sintered in a protective atmosphere at 700°C for 4 hours.

[0069] 3. Add lithium source, fluorine source and additive B to the product of step 2 according to the molar ratio of 1:1.1:1.2:0.3, mix evenly, and dry.

[0070] 4. Sinter at 650°C for 0.8h in a protective atmosphere, crush and grind to obtain the target material powder LiVPO 4 F.

[0071] The vanadium source is V 2 o 5 and N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com