Ultrasonic-assisted membrane distilled water treatment system and method

An ultrasonic-assisted membrane and treatment system technology, applied in water/sewage treatment, pressure-condition water treatment, water/sludge/sewage treatment, etc. Affecting the effect of membrane distillation and other problems, to achieve the effect of simple process, slowing down the phenomenon of concentration polarization, controllable processing rate and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

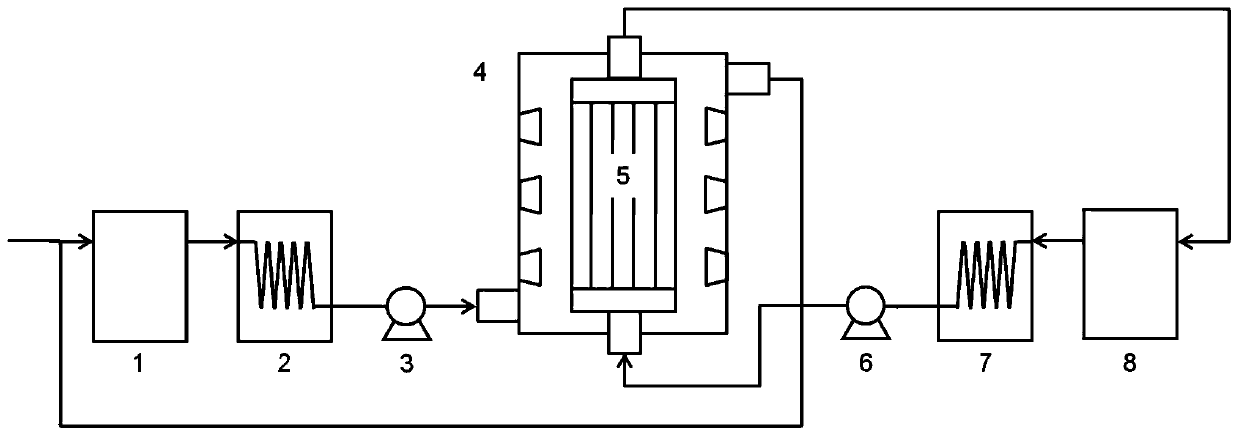

[0045]The waste water in the raw water tank 1 is preheated to 80°C by the heater 2, and pumped into the cavity of the ultrasonic-assisted membrane distillation tank 4 through the water inlet pump 3; the cooling water in the cooling water tank 8 is cooled to 20°C by the cooler 7, and then The water circulation pump 6 is driven into the inside of the membrane module 5; since the outside of the membrane module is wastewater with a higher temperature and the inside is cooling water with a lower temperature, there is a difference in steam pressure on both sides, driving the water on the wastewater side to enter through the membrane in the form of steam. On the cooling water side, due to the temperature drop, it condenses into a liquid on the cooling water side; turn on the ultrasonic generator, adjust the working frequency to 40kHz, and the power density to 0.3W / cm 2 , adopt the intermittent action mode, open for 1 minute every 10 minutes, the permeation flux of the membrane is impr...

Embodiment 2

[0047] like figure 1 As shown, the ultrasonic-assisted membrane distilled water treatment system of this embodiment includes a raw water tank 1, a heater 2, an inlet water pump 3, an ultrasonic-assisted membrane distillation tank 4, a membrane module 5, a cooling water circulation pump 6, a cooler 7 and a cooling water tank 8, The microporous filter membrane in the membrane module 5 adopts a combined membrane module of PVDF membrane and PP membrane.

[0048] The wastewater in the raw water tank 1 is preheated to 40°C by the heater 2, and pumped into the chamber of the ultrasonic-assisted membrane distillation tank 4 through the water inlet pump 3; the cooling water in the cooling water tank 8 is cooled to 5°C by the cooler 7, and then The water circulation pump 6 is driven into the inside of the membrane module 5; since the outside of the membrane module is wastewater with a higher temperature and the inside is cooling water with a lower temperature, there is a difference in s...

Embodiment 3

[0050] like figure 1 As shown, the ultrasonic-assisted membrane distilled water treatment system of this embodiment includes a raw water tank 1, a heater 2, an inlet pump 3, an ultrasonic-assisted membrane distillation tank 4, a membrane module 5, a cooling water circulation pump 6, a cooler 7 and a cooling water tank 8; The membrane module 5 adopts a combined membrane module of hollow fiber filter membrane, plate filter membrane and tubular filter membrane, and the material is PTFE membrane.

[0051] The waste water in the raw water tank 1 is preheated to 100°C by the heater 2, and pumped into the cavity of the ultrasonic-assisted membrane distillation tank 4 through the water inlet pump 3; the cooling water in the cooling water tank 8 is cooled to 20°C by the cooler 7, and then The water circulation pump 6 is driven into the inside of the membrane module 5; since the outside of the membrane module is wastewater with a higher temperature and the inside is cooling water with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com