A three-dimensional high-temperature continuous heat treatment production system environmental protection device

A technology of production system and environmental protection device, which is applied in the field of environmental protection device of three-dimensional high-temperature continuous heat treatment production system, can solve problems such as environmental pollution, and achieve the effects of reducing pollution, improving efficiency, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

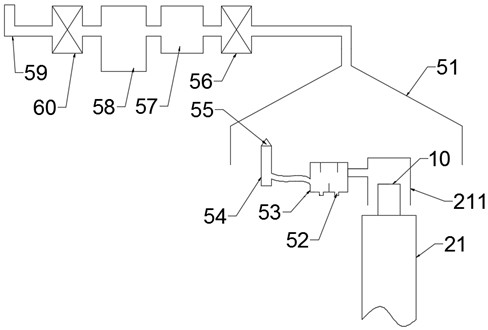

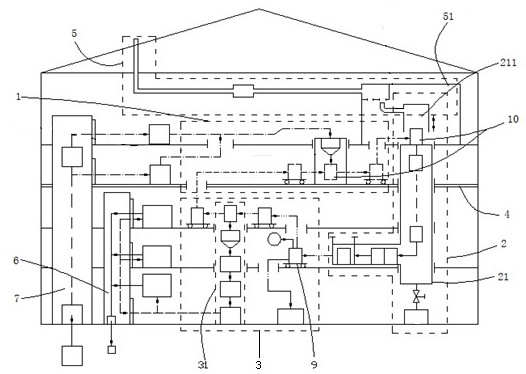

[0027] Such as figure 1 and 2 As shown, the present invention provides a three-dimensional high-temperature continuous heat treatment production system environmental protection device, which can be used to treat waste gas generated by heat treatment furnaces. The environmental protection device acts on the three-dimensional high-temperature continuous heat treatment production system, which is mainly used for carbonization and graphitization of graphite powder raw materials. The production system is set in a multi-storey production workshop, including a loading module 1 , a heat treatment module 2 , an unloading module 3 , an environmental protection device 5 , an electrical control module (not shown), and a raw material input channel 7 .

[0028] According to the structural size of each module in the production system, the multi-storey production workshop in this embodiment is set to 5 floors. The workshop is divided into high-rise and low-rise. Raw materials are placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com