Transparent conductive paste, transparent grid line and solar cell

A transparent conductive and paste technology, applied in the field of solar cells, can solve the problems of increasing the series resistance of solar cells, reducing the conversion efficiency of solar cells, and adversely reducing the cost of solar cells, and achieves good current collection effect, large width and thickness, and cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] According to another aspect of the present invention, there is provided a method for preparing the above-mentioned transparent conductive paste, comprising the following steps:

[0042] The raw materials for preparing the transparent conductive paste are mixed according to the proportion, dispersed and filtered to obtain the transparent conductive paste.

[0043] Dispersion can be carried out, for example, in the range of 20-30°C, for example, at room temperature, and the dispersion time can be 10 min, 15 min, 20 min, etc. Filtration can be performed, for example, with a filter, and the filter can be 100 mesh, 200 mesh, or 300 mesh.

[0044] According to another aspect of the present invention, a transparent grid line is provided, and the transparent grid line is obtained by curing the transparent conductive paste of the present invention.

[0045] "Curing" in the present invention refers to the process of changing the transparent conductive paste from non-solid to sol...

Embodiment approach

[0062] According to one embodiment of the present invention, the solar cell is a solar cell sheet.

[0063] The technical solutions of the present invention will be further explained and described below in conjunction with specific embodiments.

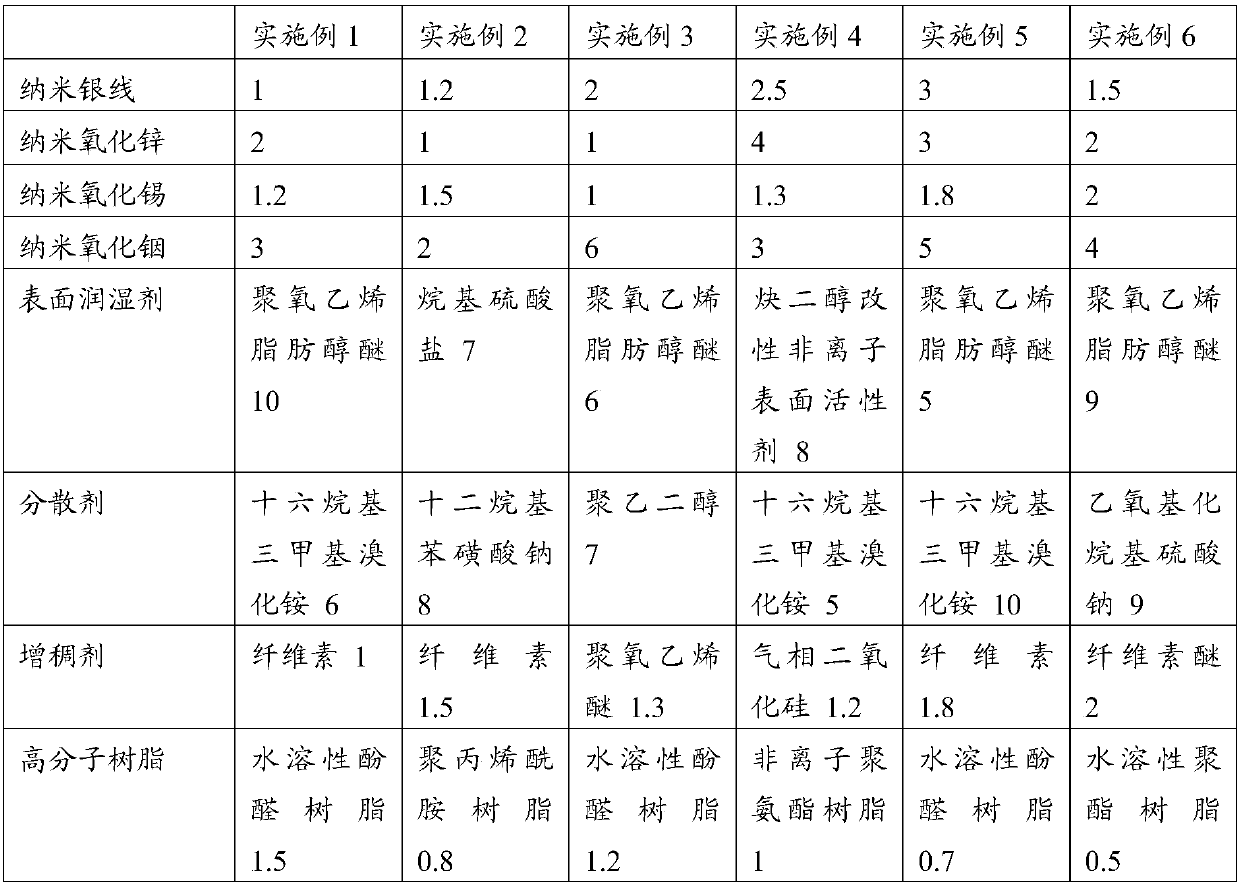

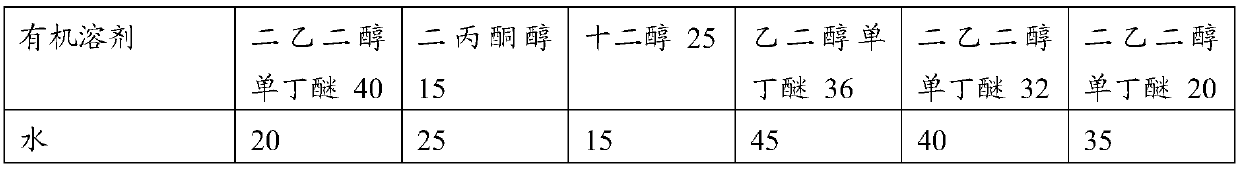

[0064] Embodiment 1~6 transparent conductive paste

[0065] Each component and its content of Examples 1-6 are shown in Table 1.

[0066] The preparation method is as follows:

[0067] The components were mixed according to the contents listed in Table 1, dispersed at room temperature for 10 minutes, and filtered through a 200-mesh filter to obtain transparent conductive pastes of various examples.

[0068] Each component and its content (parts by weight) in the embodiment of table 1

[0069]

[0070]

Embodiment A

[0076] The preparation method of the front grid lines of Examples A~C and Comparative Examples A~C is:

[0077] S101: printing the transparent conductive paste on the surface of the solar cell substrate with a screen printing machine;

[0078] S102: Slowly raise the temperature of the substrate printed with the paste from room temperature to 40° C. in argon gas, keep it for 15 minutes, remove moisture and set the shape.

[0079] S103: Fill the high temperature furnace with 10vt% H 2 Argon, heated to 700°C for 1.5 minutes.

[0080] S104: cooling down to room temperature at a cooling rate of 5° C. / min to form front grid lines of the solar cells.

[0081] In Example D, in step S102, the temperature was slowly raised from room temperature to 60°C, and kept for 5 minutes; in step S103, the temperature was heated to 800°C, and the heating time was 1.2 minutes. Others were the same as in Example A.

[0082] In Example E, the temperature was heated to 800° C. in step S103 for 1.2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com