Dragon fruit full-fruit powder and preparation method thereof

A technology of pitaya peel and pitaya, applied in the field of pitaya whole fruit powder and preparation thereof, can solve problems such as low cost, and achieve the effects of low cost, outstanding health care function, and uniform and turbid appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

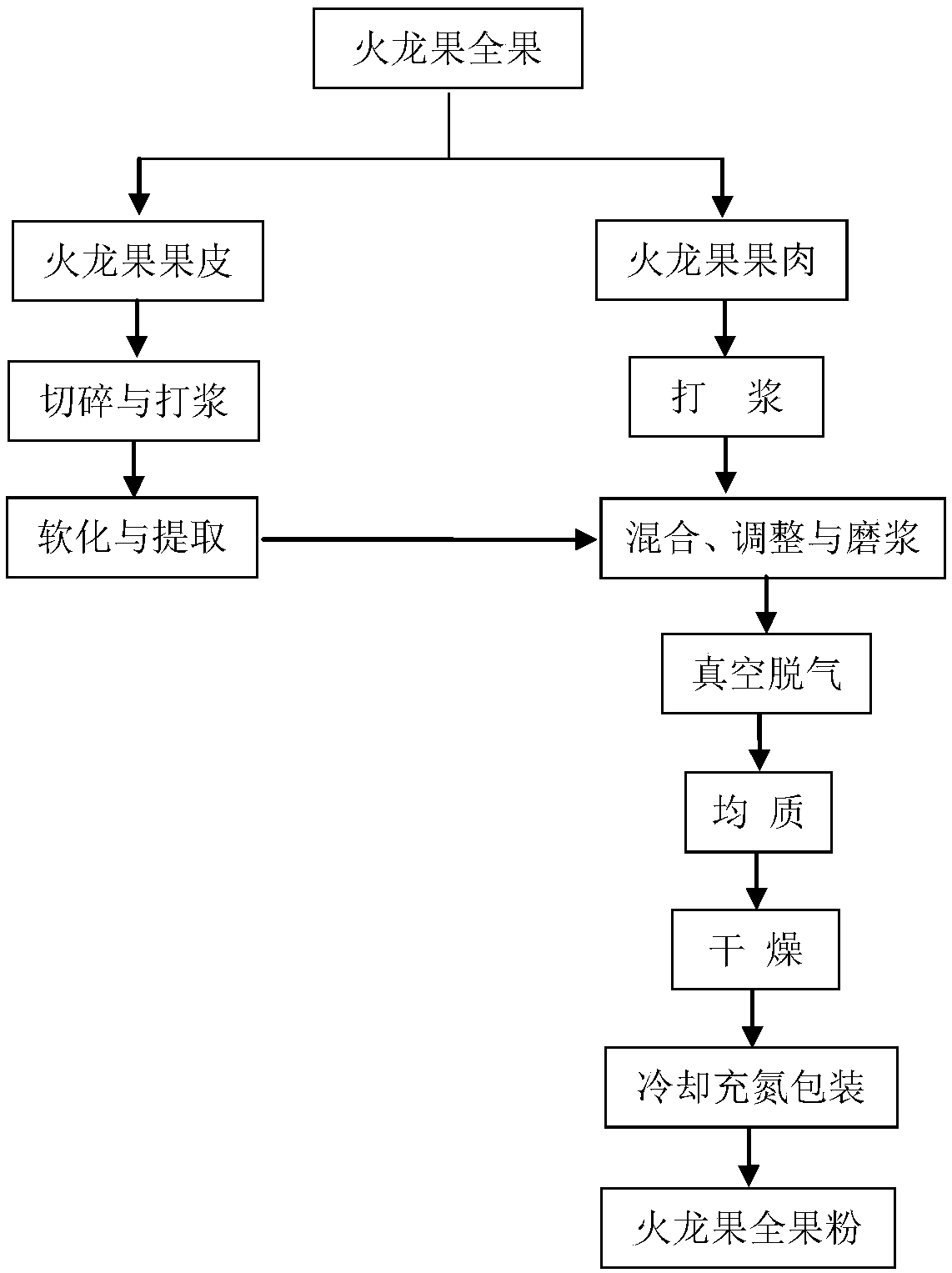

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of dragon fruit whole fruit powder, comprises the steps:

[0036] (1) Cleaning and cutting: Take dragon fruit with red skin and red flesh, wash the dragon fruit with flowing tap water, wash away the dust, sediment and other impurities on the surface, take out 50kg of the drained dragon fruit; cut it with a stainless steel knife Dragon fruit, separate pitaya pulp and pitaya peel, get dragon fruit peel 16kg and pitaya pulp 34kg, store in clean container respectively for subsequent use;

[0037] (2) Pitaya peel chopping and beating: get step (1) gained dragon fruit peel, with stainless steel knife or stainless steel shredder, dragon fruit peel is cut into the fritter that length * width is 3.5cm * 1.3cm; To 16kg Add 16kg of softening and color-protecting liquid in the small pieces of pitaya peel, stir and mix, and beat with a stainless steel beater to obtain dragon fruit peel slurry, which is for subsequent use; % trisodium citrate and mass pe...

Embodiment 2

[0044] A kind of preparation method of dragon fruit whole fruit powder, comprises the steps:

[0045] (1) Cleaning and cutting: Take the dragon fruit with red skin and red flesh, wash the dragon fruit with flowing tap water, wash away the dust, sediment and other impurities on the surface, take out the drained dragon fruit 517kg; cut it with a stainless steel knife Dragon fruit, separate pitaya pulp and pitaya peel, get dragon fruit peel 140kg and pitaya pulp 377kg, store in clean container respectively for subsequent use;

[0046] (2) Mincing and beating of pitaya peel: get step (1) gained pitaya peel, with stainless steel knife or stainless steel shredder, dragon fruit peel is cut into the fritter that length * width is 4.5cm * 2cm; To the pitaya of 140kg Add 84kg of softening and color-protecting solution in the small pieces of fruit peel, stir and mix, and beat with a stainless steel beater to obtain dragon fruit peel slurry, which is for subsequent use; wherein, the softe...

Embodiment 3

[0053] A kind of preparation method of dragon fruit whole fruit powder, comprises the steps:

[0054] (1) Take dragon fruit with red peel and purple red flesh, wash it with flowing tap water, wash away the dust, silt and other impurities on the surface, take it out and drain it; weigh 722kg of the drained dragon fruit, and cut the dragon fruit with a stainless steel knife , separate pulp and pericarp, get dragon fruit pericarp 210kg and pitaya pulp 512kg, store in clean container respectively for subsequent use;

[0055] (2) pitaya peel chopping and beating: get step (1) gained pitaya peel, with stainless steel knife or stainless steel shredder, pitaya peel is cut into the fritter that length * width is 3cm * 2cm; To the pitaya of 210kg Add 150kg of softening and color-protecting solution to the peel pieces, stir and mix, beat with a stainless steel beater to obtain dragon fruit peel slurry, and set aside; wherein, the softening and color-protecting solution is 0.35% by mass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com