Preparation method of porous hydroxyapatite supported platinum catalyst

A technology of hydroxyapatite and platinum catalysts is applied in the preparation of organic compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc. , the effect of uniform aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

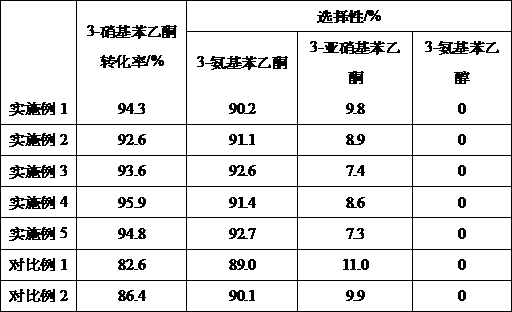

Examples

Embodiment 1

[0026] The preparation method of porous hydroxyapatite supported platinum catalyst comprises the following steps:

[0027] S1. Weigh and prepare the alcohol solutions of calcium nitrate and phosphorus pentoxide respectively, and then put P 2 o 5 Alcoholic solution was added dropwise to Ca(NO 3 ) 2 4H 2 In the solution of O, heat and stir to obtain a colorless transparent solution;

[0028] S2. Dehydrate lanthanum nitrate, and then La(NO 3 ) 3 Doping with the colorless transparent solution in step S1 in proportion, and fully reacting, wherein, the molar ratio of (Ca+La) / P is 1.67, and the molar ratio of Ca and La is 9.5:0.5;

[0029] S3. After the reaction is complete, add sodium hexametaphosphate, and adjust the pH to obtain a sol;

[0030] S4. Ultrasonic treatment is performed on the sol. The ultrasonic treatment method is the first 12h, ultrasonic treatment for 3min every 0.5h, and then every 24h, ultrasonic treatment for 2min;

[0031] S5. After ultrasonic treatment...

Embodiment 2

[0034] The preparation method of porous hydroxyapatite supported platinum catalyst comprises the following steps:

[0035] S1. Weigh and prepare the alcohol solutions of calcium nitrate and phosphorus pentoxide respectively, and then put P 2 o 5 Alcoholic solution was added dropwise to Ca(NO 3 ) 2 4H 2 In the solution of O, heat and stir to obtain a colorless transparent solution;

[0036] S2. dehydrate the lanthanum nitrate, then Ce(NO 3 ) 3 Doping with the colorless transparent solution in step S1 in proportion, and fully reacting, wherein, the molar ratio of (Ca+Ce) / P is 1.67, and the molar ratio of Ca and Ce is 9:1;

[0037] S3. After the reaction is complete, add sodium polyacrylate, and adjust the pH to obtain a sol;

[0038] S4. Ultrasonic treatment is performed on the sol. The ultrasonic treatment method is the first 12 hours, ultrasonic treatment for 5 minutes every 1 hour, and then every 24 hours, ultrasonic treatment for 4 minutes;

[0039] S5. After ultraso...

Embodiment 3

[0042] The preparation method of porous hydroxyapatite supported platinum catalyst comprises the following steps:

[0043] S1. Weigh and prepare the alcohol solutions of calcium nitrate and phosphorus pentoxide respectively, and then put P 2o 5 Alcoholic solution was added dropwise to Ca(NO 3 ) 2 4H 2 In the solution of O, heat and stir to obtain a colorless transparent solution;

[0044] S2. Dehydrate lanthanum nitrate, and then Nd(NO 3 ) 3 Doping with the colorless transparent solution in step S1 in proportion, and fully reacting, wherein, the molar ratio of (Ca+Nd) / P is 1.67, and the molar ratio of Ca and Nd is 9.3:0.7;

[0045] S3. After the reaction is complete, add sodium hexametaphosphate or sodium polyacrylate, and adjust the pH to obtain a sol;

[0046] S4. Ultrasonic treatment is carried out on the sol, the ultrasonic treatment method is the first 12h, every 0.5h ultrasonic treatment for 5min, and then every 24h, ultrasonic treatment for 3min;

[0047] S5. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com