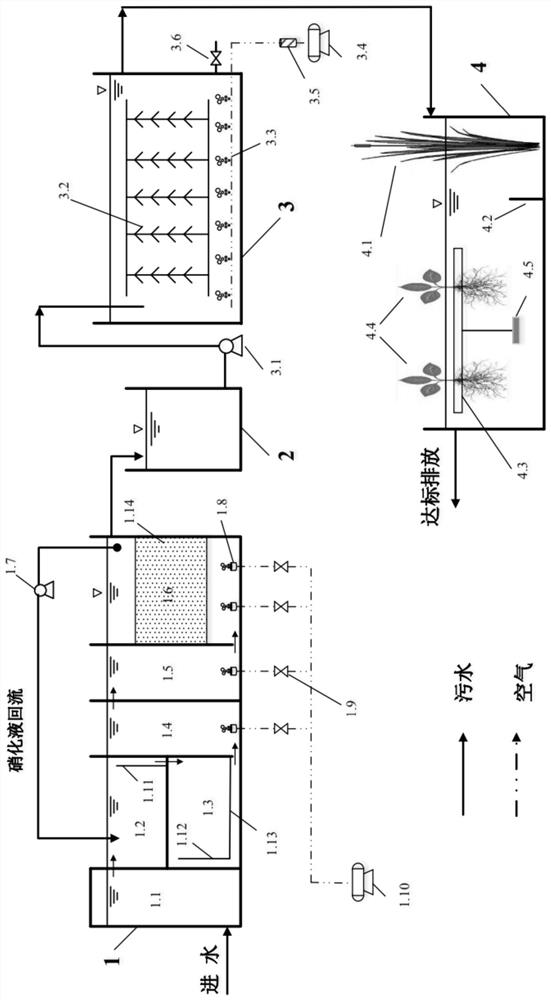

A biogas slurry deep purification system based on sharon - SBBR - improved ecological floating bed combined process

An ecological floating bed, deep purification technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of unstable reaction system, affecting treatment efficiency, affecting effluent quality, etc. Achieve the effect of reducing construction and operating costs, improving pollution purification efficiency, and improving the degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

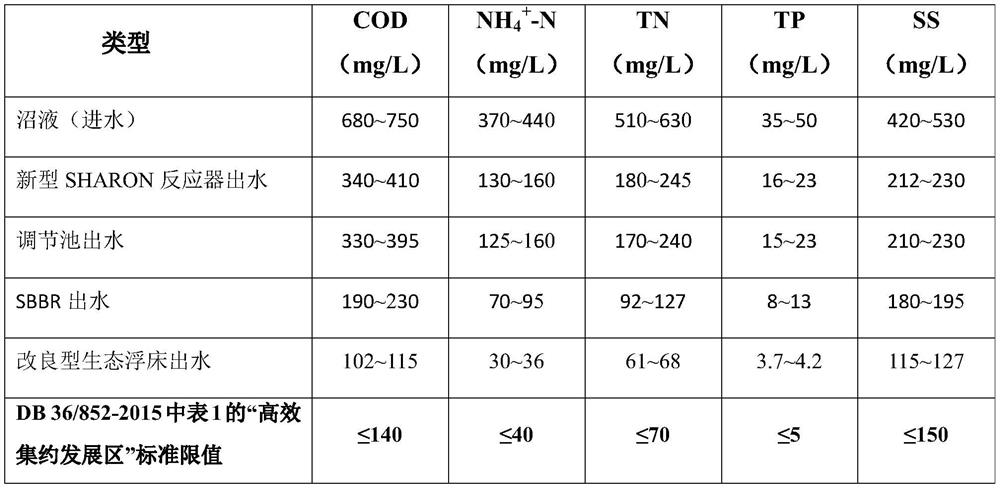

Embodiment 1

[0043] A medium-sized pig farm with a daily waste water volume of about 50m 3 / d, using the dry cleaning method to reduce the content of suspended particles flowing into the anaerobic septic tank, and then pump the generated biogas slurry into the system composed of SHARON-SBBR-improved ecological floating bed combination process for deep purification. The corresponding equipment operates according to the relevant parameters mentioned above. Among them, the nitrifying liquid reflux ratio of the new SHARON reactor is controlled at 100%, and the SBBR operation cycle is automatically controlled by PLC to 12h / week, specifically: the water intake period is 0.5h (aeration), and the reaction The period is 8.5h (aeration, including the first 0.5h water inflow period), the decanting period is 2.0h (no aeration, the first 1.5h is standing, and the last 0.5h is draining), and the standing period is 1.5h (no aeration). Through more than half a year of operation monitoring, it is found tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com