Device and method for slowing down membrane pollution

A membrane fouling and membrane pool technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of small head loss, low operating cost and high water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

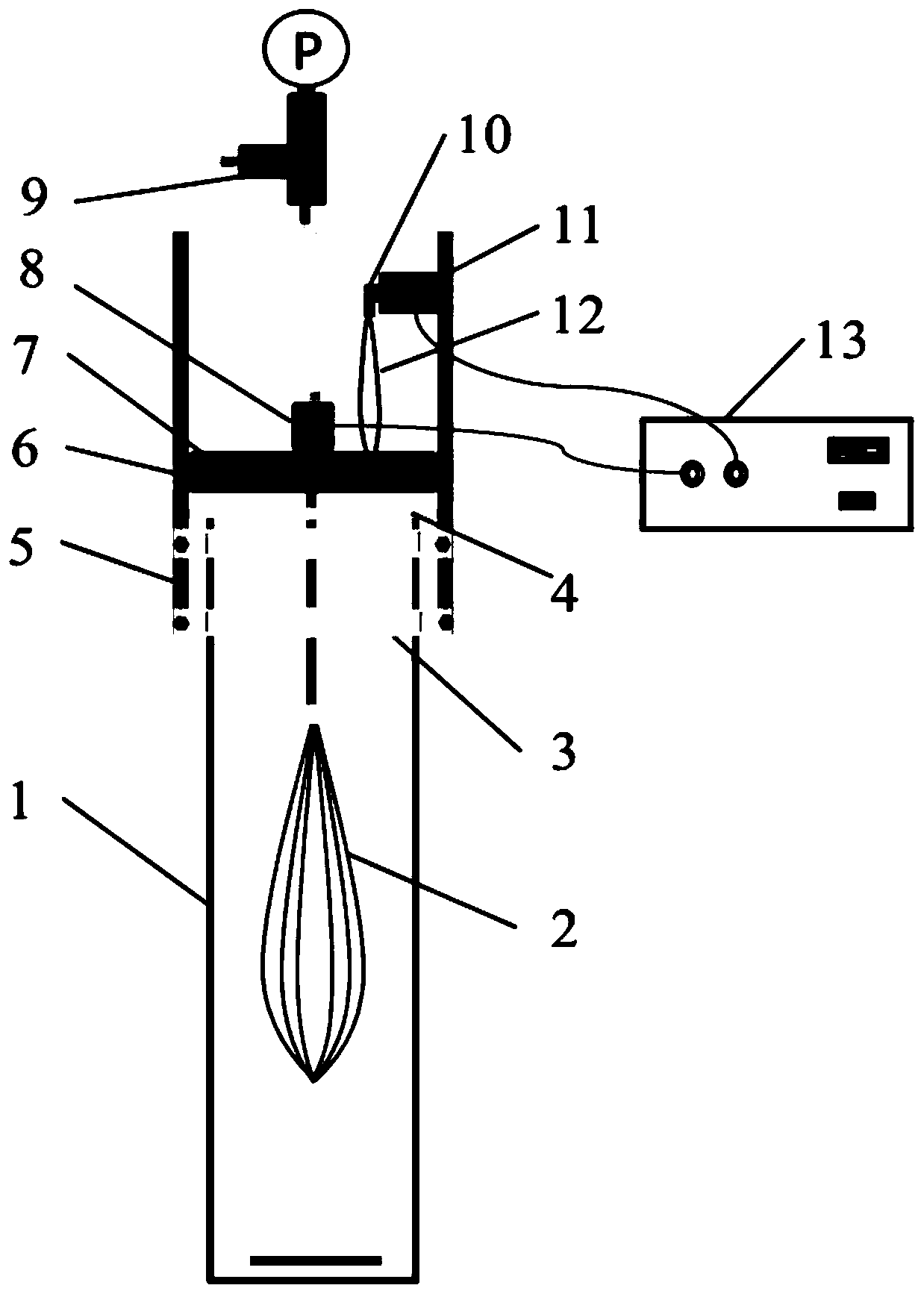

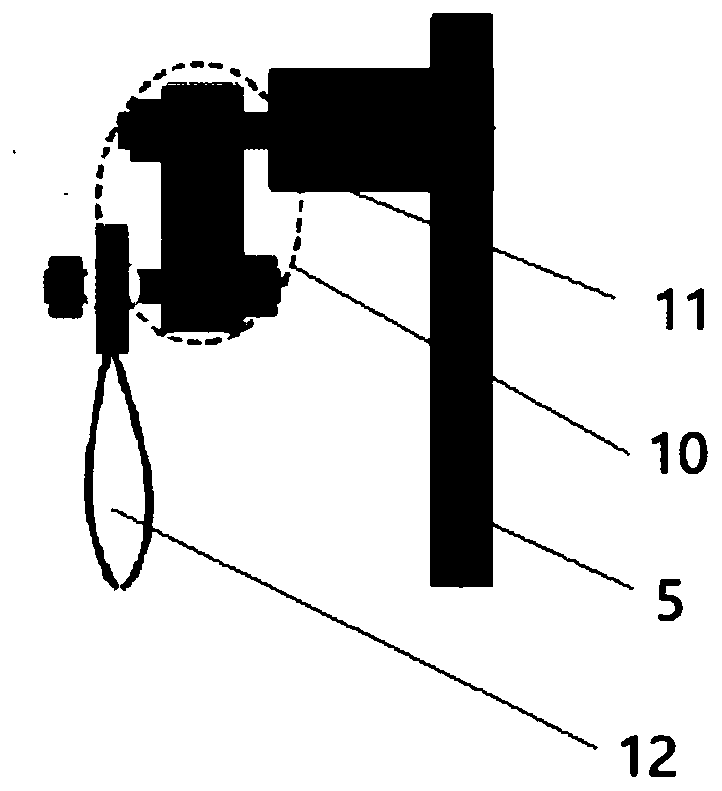

[0080] Example 1 A method for slowing down membrane fouling, specifically comprising:

[0081] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-5 mg / L. Adopt conventional adsorption-membrane treatment process. Continue to add powdered activated carbon, 5mg / L per day. The raw water is pumped into the powdered activated carbon pool and then enters the membrane pool at 1L / h. The hydraulic retention time in the membrane pool is 0.5h. The membrane module is an ultrafiltration membrane, and the rotation mode of the membrane module is: helical intermittent rotation (times / 6h), forward and reverse rotation each 1 turn, helix height 1cm, each rotation 10 minutes, rotation frequency 20rpm / min. After 15 days of continuous operation, the transmembrane pressure difference increased to 17kPa.

Embodiment 2

[0084] Example 2 A method for slowing down membrane fouling, specifically comprising:

[0085] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-5 mg / L. Conventional coagulation membrane treatment process (conventional equipment including independent coagulation unit, precipitation unit and membrane treatment unit) is adopted. Continue to add aluminum salt coagulant, calculated as aluminum, 5mg / L per day. Among them, the mechanical stirring is fast rotation (200rpm) 1min, slow rotation (50rpm) 15min. Pump the raw water into the coagulation tank, pass through the sedimentation tank and then enter the membrane tank at 1L / h. The hydraulic retention time in the membrane tank is 0.5h. The membrane module is an ultrafiltration membrane, and the rotation mode of the membrane module is: reciprocating intermittent rotation (times / 6h), forward and reverse rotation each 1 circle, each rotation is 10 minutes, and ...

Embodiment 3

[0088] Example 3 A method for slowing down membrane fouling, specifically comprising:

[0089] This embodiment is raw water treatment, and the content of dissolved organic carbon (DOC) in the water to be treated is 2-5 mg / L. Short-flow process (conventional equipment including independent coagulation unit and membrane treatment unit) is adopted. Continue to add aluminum salt coagulant, calculated as aluminum, 5mg / L per day. Among them, the mechanical stirring is fast rotation (200rpm) 1min, slow rotation (50rpm) 15min. Pump the raw water into the coagulation tank, and enter the membrane tank at 1L / h. The hydraulic retention time in the membrane tank is 0.5h. The membrane module is an ultrafiltration membrane, and the rotation mode of the membrane module is: helical intermittent rotation (6h / time), forward and reverse rotation each 1 turn, helix height 1cm, each rotation 10 minutes, rotation frequency 20rpm / min. After 15 days of continuous operation, the transmembrane pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com