Application of a composite film material as an energy storage material and its preparation method

A composite film and polymer technology, applied in the direction of thin film/thick film capacitors, fixed capacitance parts, laminated capacitors, etc., can solve the problem of low energy storage efficiency, achieve high energy storage efficiency, high temperature resistance, Effect of low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

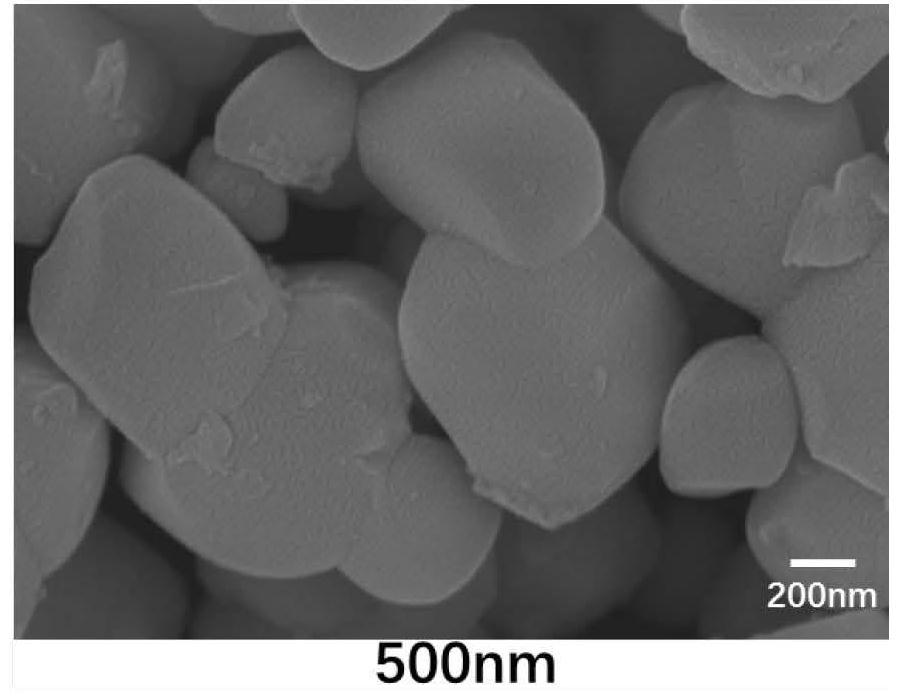

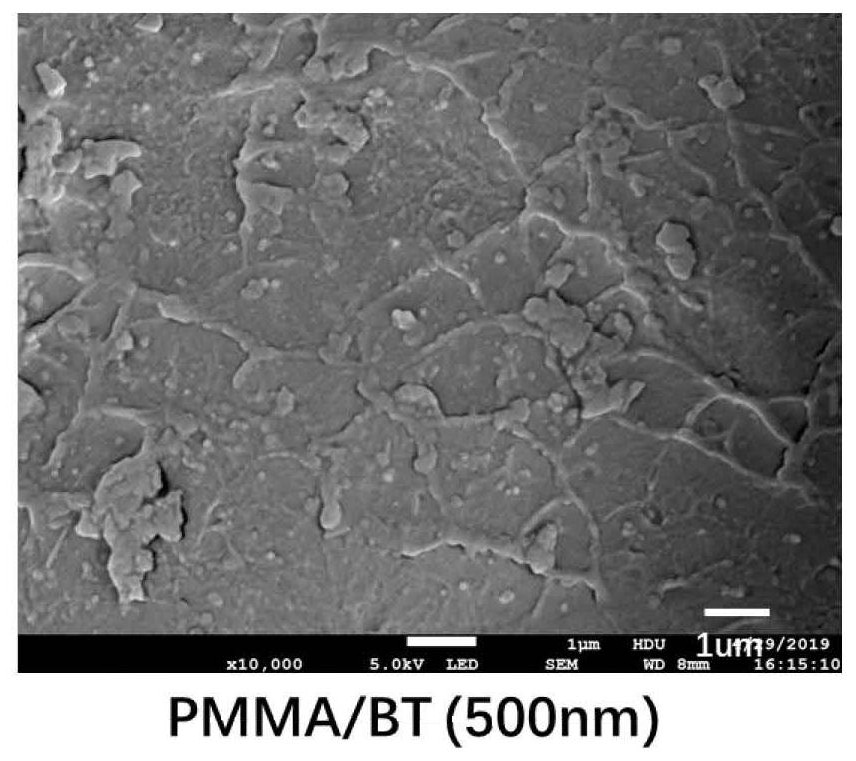

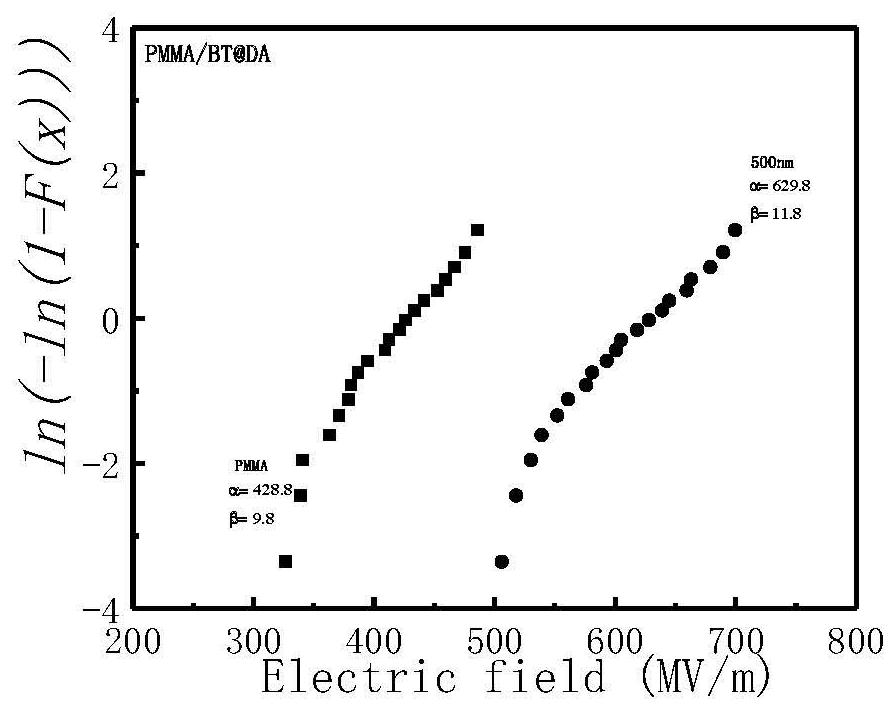

[0036] A high-temperature-resistant composite film material based on submicron ceramic fillers includes a base polymer and a ceramic filler doped in the base polymer; the ceramic filler adopts barium titanate ceramic particles with a particle size of 500nm. The ceramic filler is surface modified to enhance the compatibility of the ceramic filler and the polymer matrix. The base polymer adopts PMMA. The mass fraction of the ceramic filler in the composite film material is 3%.

[0037] The surface modification of barium titanate ceramic particles with a particle size of 500nm enhances the compatibility between the ceramic filler and the polymer matrix; after dissolving the PMMA as the base polymer with a polar solvent, adding a certain amount of titanium Put the barium acid ceramic particles into the PMMA solution to prepare a composite solution, cast the composite film material by casting method, dry it at 150-250°C to obtain the composite material, and obtain the PMMA / DBT (50...

Embodiment 2

[0047] The aforementioned preparation method based on submicron ceramic filler high temperature resistant composite film material (i.e. PMMA / DBT (500nm) composite material) comprises the following processing steps:

[0048] (1) Add a certain amount of base polymer into the polar solution, place it at 40-80°C and stir it for 6-12 hours until it is completely dissolved to form a clear and transparent polymer solution; the material of base polymer and polar solution The liquid ratio is 3-100g / L. The base polymer adopts PMMA.

[0049] (2) Adding a certain amount of surface-modified ceramic filler into the polymer solution obtained in step (1), fully stirring, ultrasonically vibrating, and so on for 2 to 5 times to form a stable suspension. The ceramic filler adopts barium titanate particles with a particle size of 500nm; the solid-liquid ratio of the ceramic filler to the polymer solution is 1-100g / L.

[0050] (3) Apply the suspension obtained in step (2) evenly to a glass sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com