Preparation method of magnesium-lithium matrix composite material reinforced by micro-nano scale reinforcement hybrid

A composite material and reinforcement technology, which is applied in the field of metal matrix composite materials and its preparation, can solve the problems of single-phase reinforcement reinforcement effect is not very prominent, micro-nano-scale reinforcement is easy to agglomerate, magnesium and lithium melt wettability is insufficient, etc. problem, to achieve the effect of increasing the capture capacity, reducing the possibility of burning, and enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example relates to a micro-nano-scale reinforcement hybrid reinforced magnesium-lithium-based composite material. In the magnesium-lithium-based composite material, the mass percentages of each component are: Li 15%, Al 1%, Zn 2%, Gd 0.5 %, TiB 2 12% of particles, 3% of carbon nanotubes, and the balance of Mg and other impurities. TiB 2 The particle size of the particles is 0.8um, the diameter of the carbon nanotube is 8nm, and the length is 1um.

[0034] This example relates to a method for preparing a micro-nano-scale reinforcement hybrid reinforced magnesium-lithium-based composite material. The process includes three stages: pretreatment of the reinforcement, smelting under a protective atmosphere, and plastic deformation:

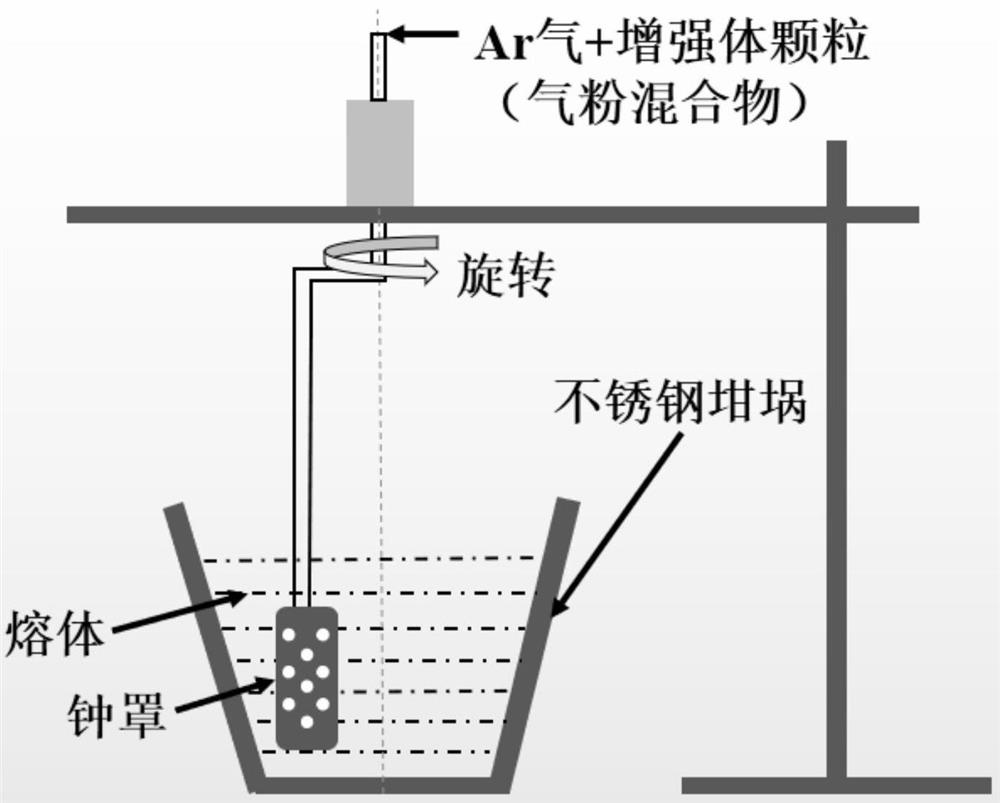

[0035] Pretreatment of reinforcement: Al plating on the surface of carbon nanotubes 2 Ce, TiB 2 The particles, carbon nanotubes and magnesium chips are mixed and ball milled on a planetary ball mill to prepare mixed powder. The low spee...

Embodiment 2

[0040] This example relates to a magnesium-lithium-based composite material reinforced by a micronanoscale reinforcement hybrid. In the magnesium-lithium-based composite material, the mass percentages of each component are: Li 10%, Al 5%, Zn 4%, Gd 2 %, TiB 2 6% of particles, 2% of carbon nanotubes, and the balance of Mg and other impurities. TiB 2 The particle size of the particles is 0.5 μm, the diameter of the carbon nanotube is 8 nm, and the length is 1 μm.

[0041] This example relates to a method for preparing a micro-nano-scale reinforcement hybrid reinforced magnesium-lithium-based composite material. The process includes three stages: pretreatment of the reinforcement, smelting under a protective atmosphere, and plastic deformation:

[0042] Pretreatment of reinforcement: Al plating on the surface of carbon nanotubes 2 Ce, TiB 2 The particles, carbon nanotubes and magnesium chips are mixed and ball milled on a planetary ball mill to prepare mixed powder. The low s...

Embodiment 3

[0047] This example relates to a magnesium-lithium-based composite material reinforced by a micronanoscale reinforcement hybrid. In the magnesium-lithium-based composite material, the mass percentages of each component are: Li 8%, Al 5%, Zn 3%, Gd 1 %, TiB 2 3% of particles, 1% of carbon nanotubes, and the balance of Mg and other impurities. TiB 2 The particle size of the particles is 0.01 μm, the diameter of the carbon nanotube is 8 nm, and the length is 1 μm.

[0048] This example relates to a method for preparing a micro-nano-scale reinforcement hybrid reinforced magnesium-lithium-based composite material. The process includes three stages: pretreatment of the reinforcement, smelting under a protective atmosphere, and plastic deformation:

[0049] Pretreatment of reinforcement: Al plating on the surface of carbon nanotubes 2 Ce, the micro-nano TiB 2 The particles, carbon nanotubes and magnesium chips are mixed and ball milled on a planetary ball mill to prepare mixed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com