Swing cylinder suspension heating direct-line generator

A generator and linear power generation technology, applied in geothermal power generation, solar thermal power generation, machines/engines, etc., can solve problems such as too long friction chain, increased liquid volume at the cold end, and inability to realize single-machine power generation, etc., and achieve stable temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

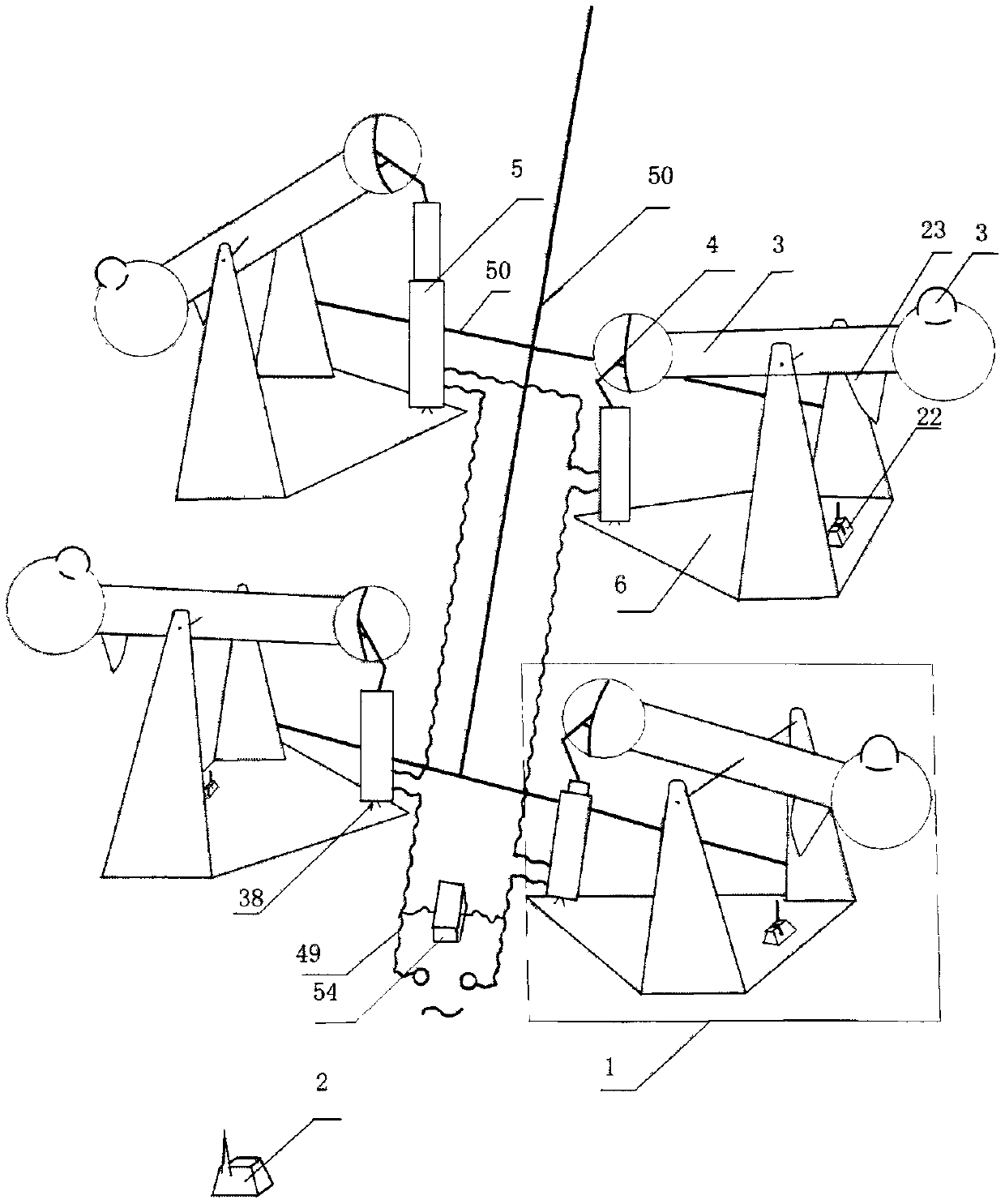

[0042] This embodiment is composed of several gas-fired swing-tube suspension heating straight generators (1), a controller (2), and chemical energy storage devices (54). The cylindrical linear power generating devices (5) are connected in series. (1) and (2) signal transmission, wireless connection, see figure 1 . The controller (2) is equipped with measurement and control software, (2) receives the monitoring signals from each straight generator (1) through the non-contact electromagnetic monitor (22) and the signal generator (53) and issues instructions to them.

[0043] Each straight generator (1) mainly includes a thermal energy converter (3) with a heating device, a connecting rod transmission mechanism (4), a cylindrical linear power generation device (5), a triangular base support frame (6) and a spherical hinge (38 ).

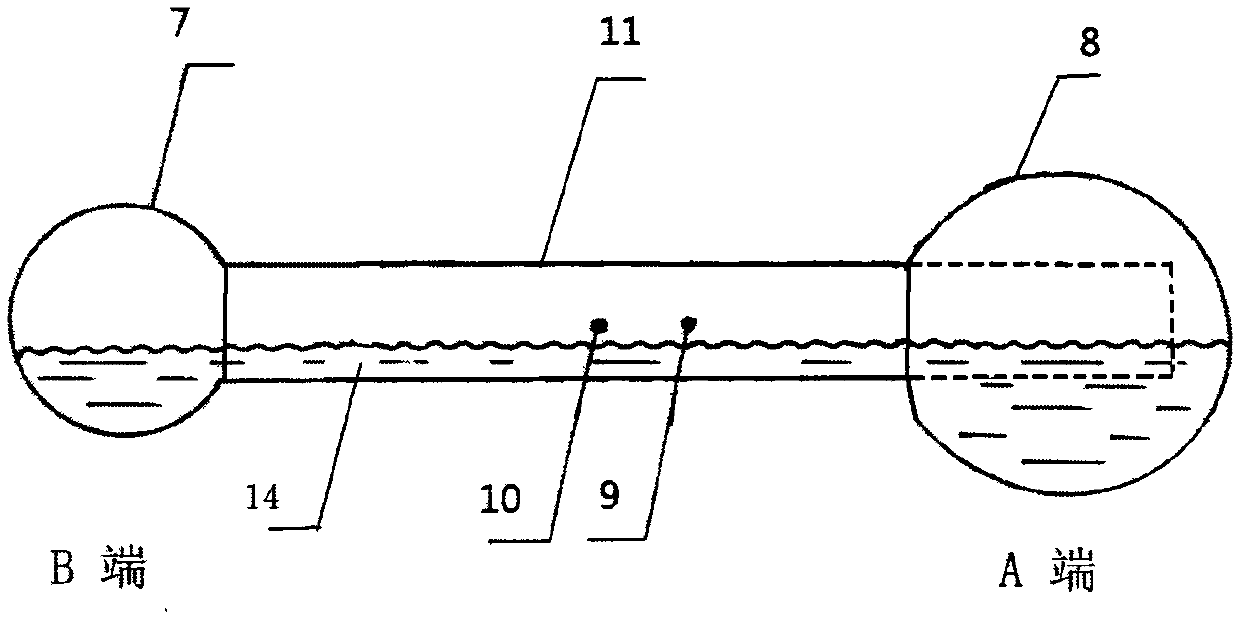

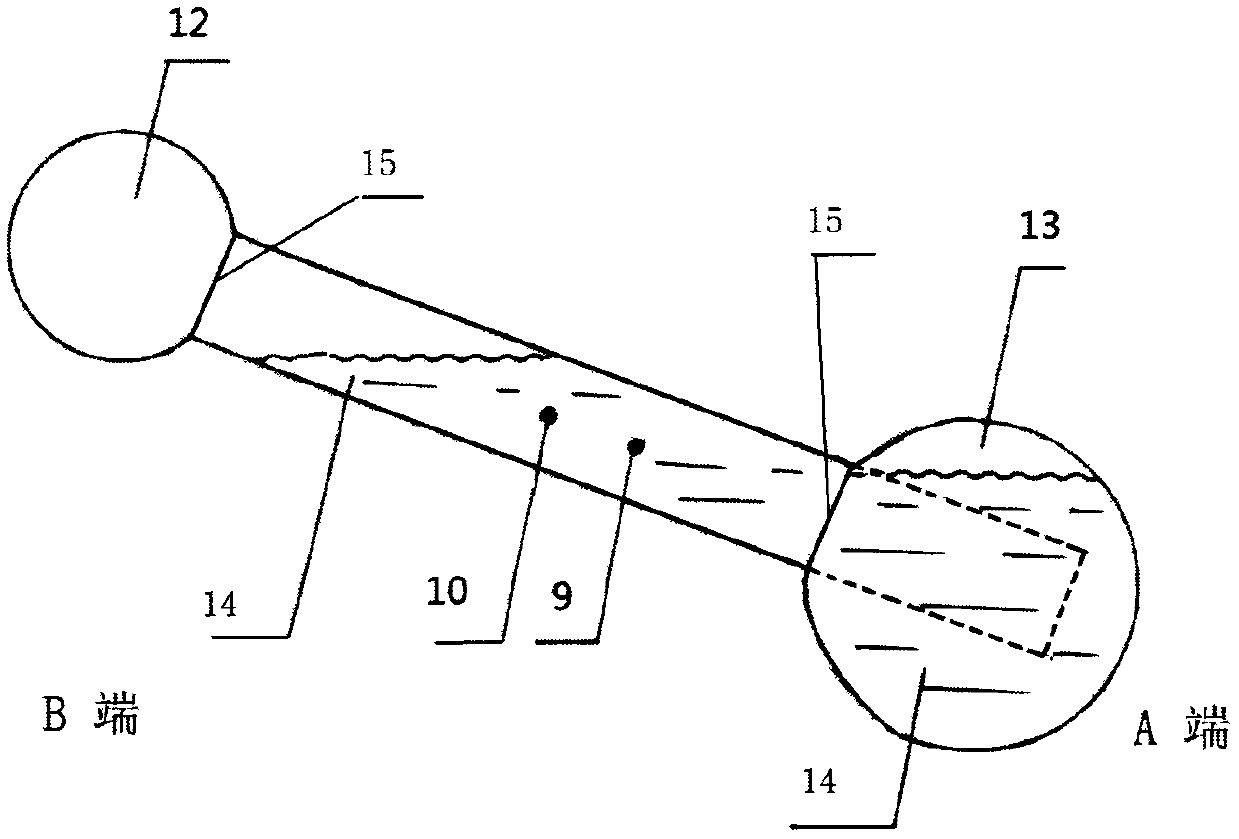

[0044] The thermal energy converter (3) is a dumbbell-shaped special aluminum-magnesium alloy airtight container, which is welded by a long tubular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com