Porosity echelon distribution pole piece, preparation method and application thereof

A technology of porosity and pole piece, which is applied in the field of pole piece with graded distribution of porosity and its preparation field, which can solve the problem of increasing the window of porosity distribution of active material layer and functional layer, difficult control of porosity distribution, unfavorable lithium Ion diffusion and other issues, to achieve the effect of improving diffusion capacity, low cost, and small porosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

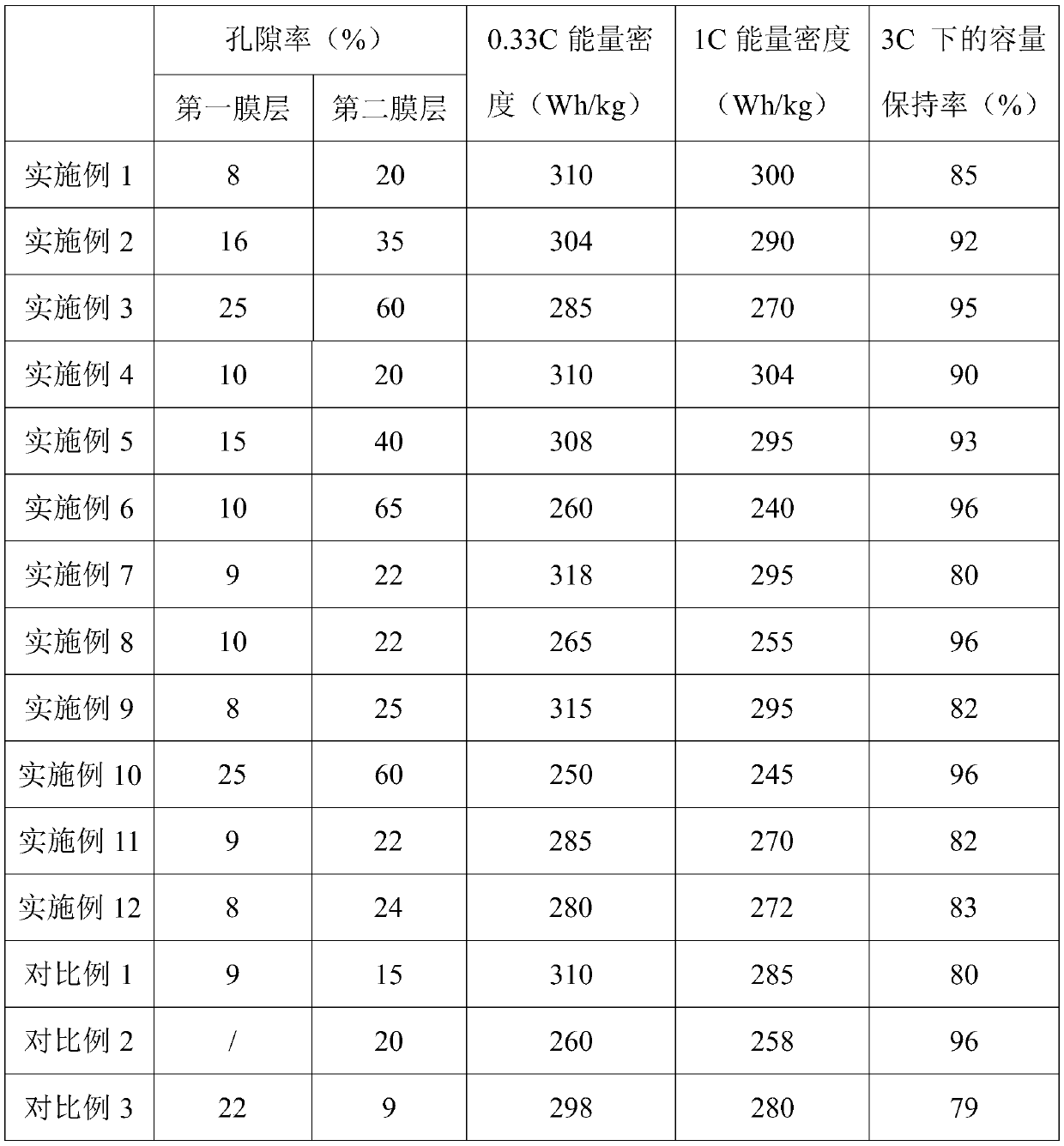

Examples

Embodiment 1

[0074] This embodiment provides a pole piece, the thickness sum of the first film layer and the second film layer of the pole piece is 190 μm, wherein, the thickness of the first film layer is 95 μm, and the porosity is 8%; the thickness of the second film layer The thickness is 95 μm and the porosity is 20%.

[0075] The preparation method of the pole piece comprises the following steps:

[0076] (1) Mix nickel-cobalt lithium manganese oxide, conductive carbon black, PVDF and NMP with a particle diameter D50 of 12 μm to obtain the first film layer slurry, and take the mass of the solid content in the first film layer slurry as 100% Calculate, control nickel cobalt lithium manganate 80%, conductive carbon black 10% and PVDF10%, the quality of NMP is 30% of above-mentioned solid component quality;

[0077] (2) the particle diameter D50 is 12 μ m nickel cobalt lithium manganese oxide, conductive carbon black, PVDF and NMP and the particle diameter D50 is the paraffin microspher...

Embodiment 2

[0080] This embodiment provides a pole piece, the thickness sum of the first film layer and the second film layer of the pole piece is 300 μm, wherein the thickness of the first film layer is 200 μm, and the porosity is 16%; the thickness of the second film layer It is 100 μm and the porosity is 35%.

[0081] The preparation method of the pole piece comprises the following steps:

[0082] (1) Graphite, conductive carbon black, SBR binder and deionized water are mixed with the particle diameter D50 of 10 μm to obtain the first film layer slurry, and the quality of the solid component in the first film layer slurry is 100 In terms of %, control graphite 90%, conductive carbon black 5%, SBR binder 5%, deionized water is 40% of the above-mentioned solid component quality;

[0083] (2) Graphite, conductive carbon black, SBR binding agent and deionized water and particle diameter D50 are mixed with refined naphthalene of 13 μm by the particle diameter D50 to obtain the second film ...

Embodiment 3

[0086] This embodiment provides a pole piece, the thickness sum of the first film layer and the second film layer of the pole piece is 400 μm, wherein the thickness of the first film layer is 200 μm, and the porosity is 25%; the thickness of the second film layer It is 200 μm and the porosity is 60%.

[0087] The preparation method of the pole piece comprises the following steps:

[0088] (1) Graphite, conductive carbon black, SBR binding agent and deionized water solvent are mixed for particle diameter D50 of 8 μm, obtain the first film layer slurry, with the quality of solid component in the first film layer slurry as 100% meter, control graphite 99%, conductive carbon black 0.3%, SBR binder 0.7%, the quality of deionized water is 50% of the above-mentioned solid component quality;

[0089] (2) Graphite, conductive carbon black, SBR binder and deionized water and particle diameter D50 are mixed with polyethylene oxide of 10 μm to obtain the second film layer slurry, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com