Ultra-high molecular weight polyolefin catalyst as well as preparation method and application thereof

A catalyst, polyolefin technology, applied in the field of polyolefin catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

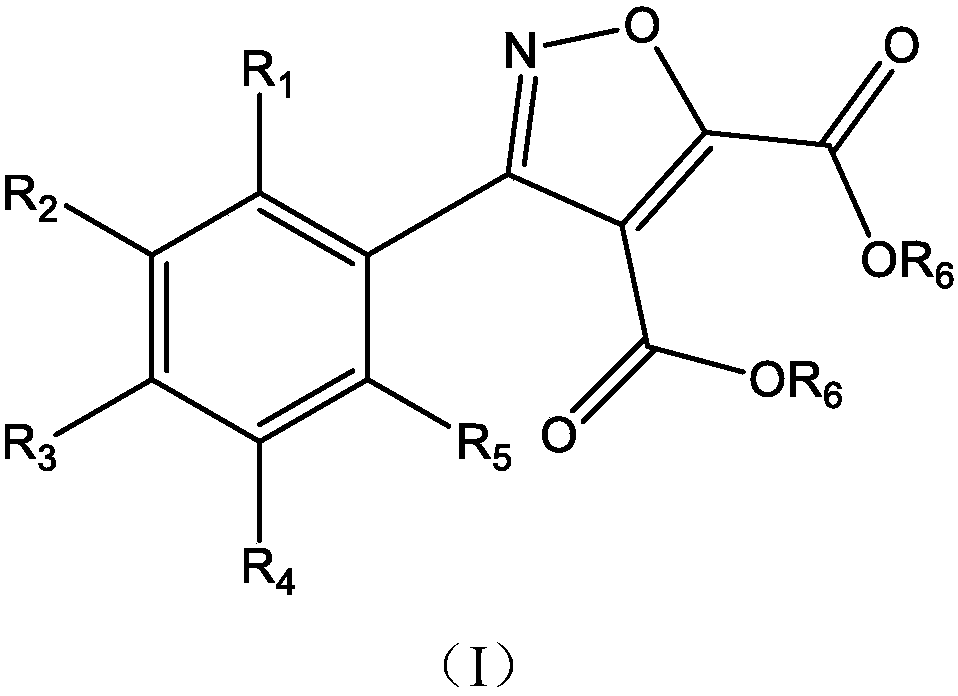

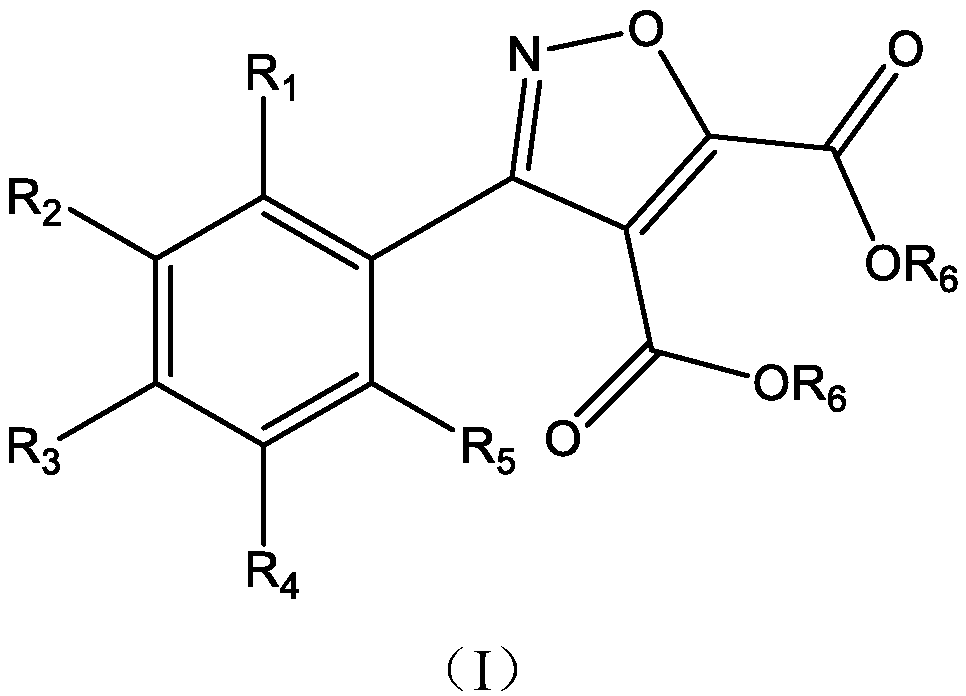

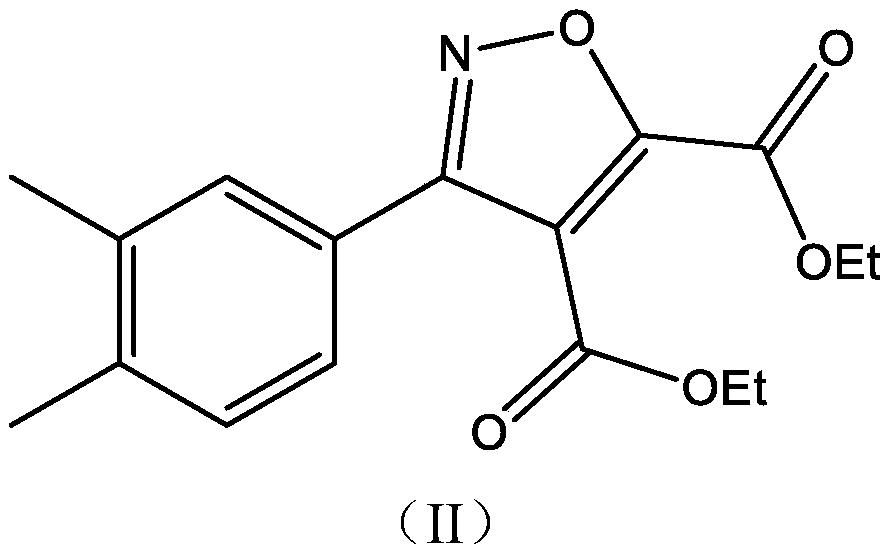

[0078] Preparation example: Synthesis of 3-(3,4-dimethylphenyl)-isoxazole-4,5-diethyl carbonate

[0079]

[0080] Replace the air with nitrogen in the reaction flask, add 12.0ml tetrahydrofuran and 1.04g 3,4-dimethylbromobenzene, cool down to -50°C, slowly add 4.62ml butyllithium (1.55mol, n-hexane), and react for 30 Minutes, add 556.0 microliters of dimethylformamide, slowly rise to room temperature, react for 1 hour, then add 624mg of hydroxylamine hydrochloride and 1.42g of potassium carbonate, react at room temperature for 2 hours, then remove the solvent, add 30.0 ml acetonitrile, 8.0ml hydrochloric acid (1.0mol / L), 22.0ml water, 1.5g diethyl propiolate, 5.46g dioxane, after three minutes, rise to room temperature, and react for 1 hour, extract with ethyl acetate , dried over sodium sulfate, and the product was isolated.

[0081] Referring to the above method, other isoxazole ester compounds used in the examples were synthesized.

Embodiment 1

[0083] A kind of preparation method of ultrahigh molecular weight polyethylene catalyst, this preparation method comprises the following steps:

[0084] (1) After dispersing 2 grams of ethoxymagnesium with 4ml octanol and 15ml n-heptane solvent, place it in a reactor under the protection of an inert gas, and then add 0.03mol 3-phenyl-isoxazole-4 to the reactor , 5-dimethyl carbonate, heated to 40°C and mixed for 2h;

[0085] (2) Cool the system prepared in step (1) to -25°C, slowly add 20ml TiCl 4 Solution, heated up to 10°C and reacted for 2 hours;

[0086] (3) Add 0.4 g of methyl tert-butyldimethoxysilane to the system prepared in step (2) and react at 80° C. for 2 hours, and filter off the supernatant after the reaction;

[0087] (4) Add 25ml TiCl to the filtered solid in step (3) 4 mixed solution with ethyl titanate, TiCl 4 The molar ratio with ethyl titanate was 1:1, and the temperature was gradually raised to 110°C for 2 hours, filtered, washed, and vacuum-dried to o...

Embodiment 2

[0090] A kind of preparation method of ultrahigh molecular weight polyethylene catalyst, this preparation method comprises the following steps:

[0091] (1) After dispersing 2 grams of ethoxymagnesium with 4ml octanol and 15ml n-heptane solvent, place it in a reactor under the protection of an inert gas, and then add 0.03mol 3-(3-isopropylphenyl )-isoxazole-4,5-diethyl carbonate, heated to 80°C and mixed for 1 hour;

[0092] (2) Cool the system prepared in step (1) to -30°C, slowly add 20ml TiCl 4 Solution, after heating up to 25°C, react for 1.5h;

[0093] (3) Add 0.4 g of diisobutyldimethoxysilane to the system prepared in step (2) and react at 80° C. for 2 hours, and filter off the supernatant after the reaction;

[0094] (4) Add 25ml TiCl to the filtered solid in step (3) 4 Mixed solution with n-butyl titanate, TiCl 4 The molar ratio with n-butyl titanate is 2:1, and the temperature is gradually raised to 90°C for 3 hours, filtered, washed, and vacuum-dried to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com