Alkyl chitosan oligosaccharide polyether, preparation method thereof and drilling fluid

A technology of alkyl chitosan oligoside polyether and alkyl chitosan oligoside, applied in the field of drilling fluid, can solve the problem that the performance cannot meet the lubrication requirements well, achieve good inhibition and compatibility performance, reduce drilling cost, improve The effect of technological competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 54g of chitosan oligosaccharide, 120g of n-octanol, and 4g of hydrochloric acid into a four-necked flask equipped with a condensing reflux and stirring device, control the stirring speed at 900r / min, and react at a temperature of 110°C for 4 hours to obtain octyl chitosan Glycoside n-octanol solution, unreacted n-octanol is removed by distillation under reduced pressure to obtain octylchitooligoglucoside;

[0042] Add 90g of propylene oxide and 5g of sodium hydroxide to the above-mentioned octylchitooligoglucoside, and react at 90°C for 2 hours at a stirring speed of 900r / min to obtain a light yellow transparent viscous octylchitooligosaccharide Glycosides.

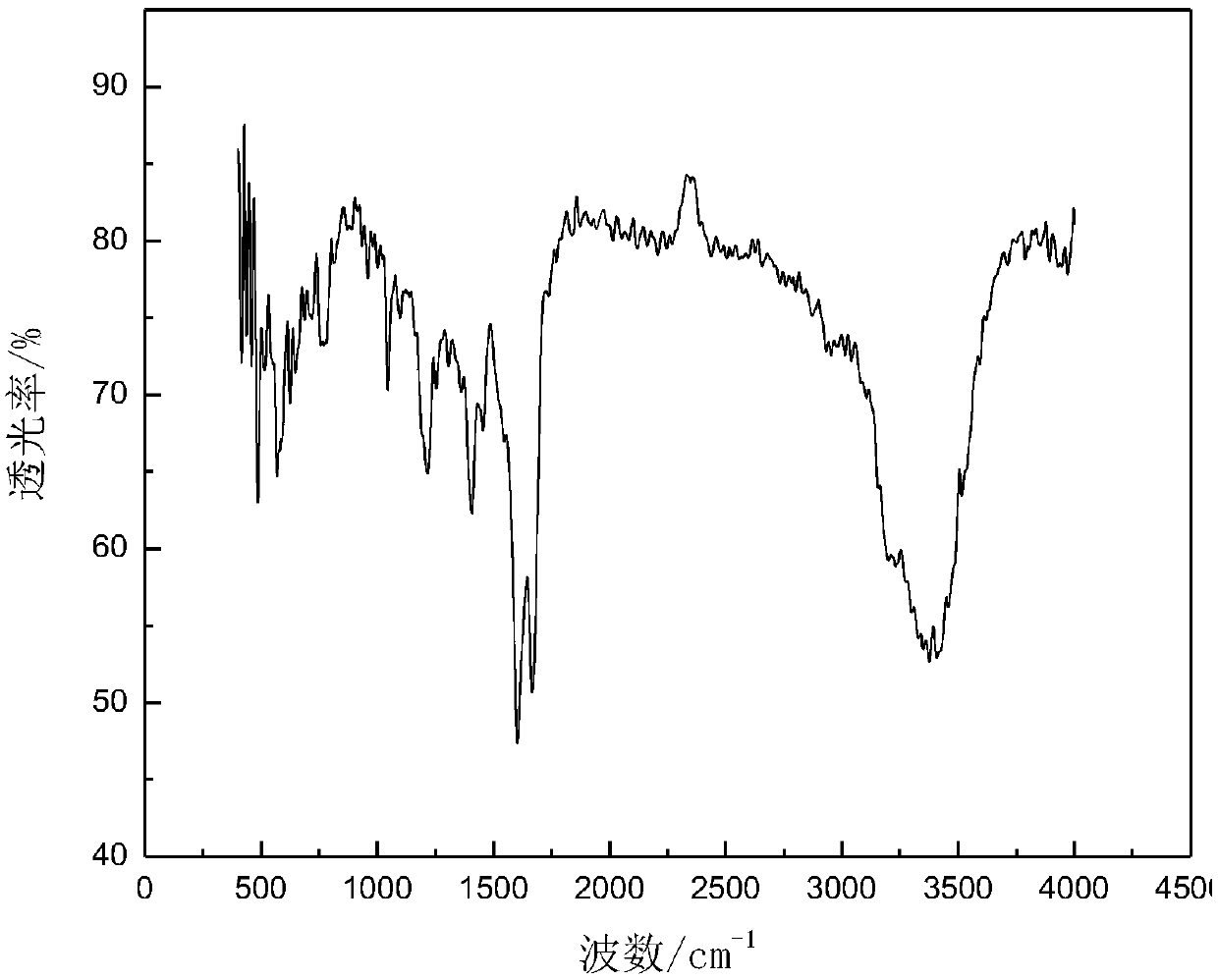

[0043] The product prepared in Example 1 of the present invention is detected by infrared spectrum, and the infrared spectrum is as follows: figure 1 As shown, the test result is: 3480cm -1 It is the stretching vibration peak of O-H bond, 2830~2950cm -1 It is the stretching vibration peak of the C-H bond in ...

Embodiment 2

[0048]Add 54g of chitosan oligosaccharide, 130g of n-decyl alcohol, and 5g of sulfuric acid into a four-necked flask with a condensing reflux and stirring device, control the stirring speed at 1000r / min, and react at a temperature of 120°C for 5 hours to obtain decyl chitosan Glycoside n-octanol solution, unreacted n-decyl alcohol was removed by distillation under reduced pressure to obtain decyl chitooligoglucoside;

[0049] Add 100g of butylene oxide and 7g of potassium hydroxide to the above-mentioned octylchitooligoglucoside, and react at 100°C for 3 hours at a stirring speed of 1000r / min to obtain a light yellow transparent viscous decyl shell Oligoglycosides.

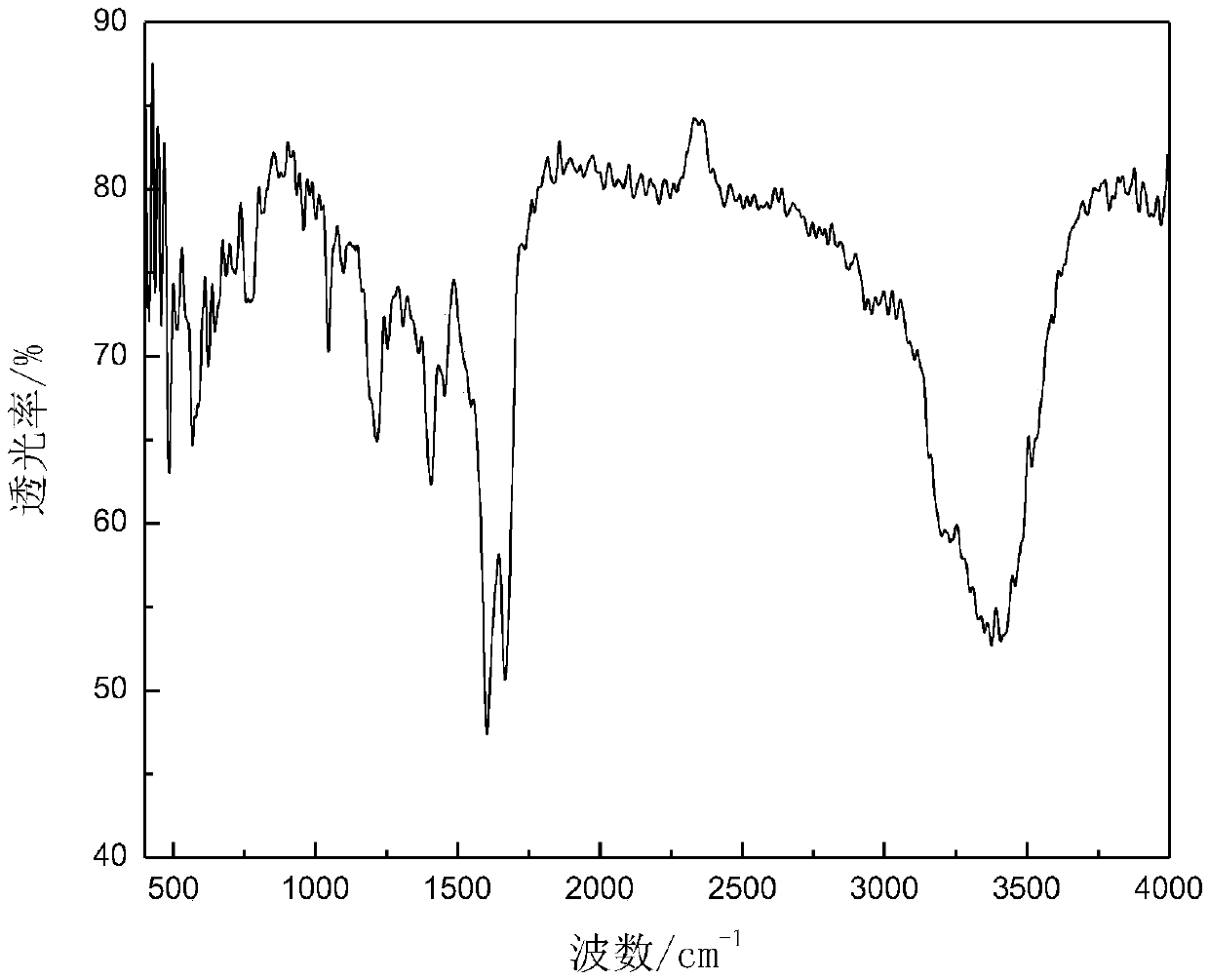

[0050] The product prepared in Example 2 of the present invention is detected by infrared spectrum, and the infrared spectrum is as follows figure 2 As shown, the test result is: 3481cm -1 It is the stretching vibration peak of O-H bond, 2830~2950cm -1 It is the stretching vibration peak of the C-H bond in met...

Embodiment 3

[0056] Add 54g chitosan oligosaccharide, 140g n-dodecyl alcohol (n-dodecanol), 6g citric acid into the four-necked flask with condensing reflux and stirring device, control the stirring speed to be 1100r / min, at 130°C React at high temperature for 6 hours to obtain dodecyl chitooligoglucoside dodecyl alcohol solution, and remove unreacted dodecyl alcohol by distillation under reduced pressure to obtain dodecyl chitooligoglucoside;

[0057] Add 110g of pentane oxide and 8g of ammonia water to the above-mentioned dodecylchitooligoglucoside, and react at 110°C for 4 hours at a stirring speed of 1100r / min to obtain light yellow transparent viscous dodecane Chitooligoglycoside polyethers.

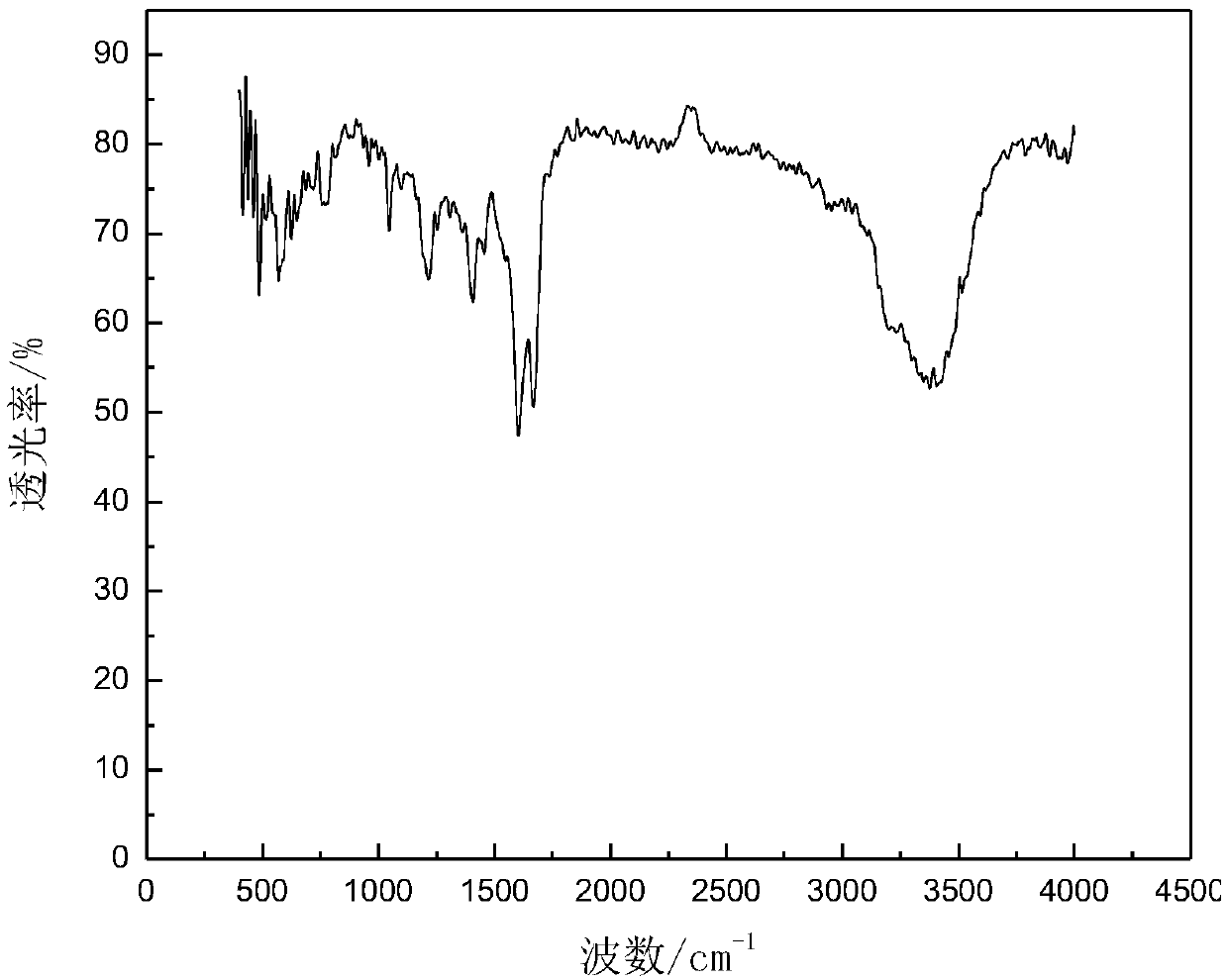

[0058] The product prepared in Example 3 of the present invention is detected by infrared spectrum, and the infrared spectrum is as follows: image 3 As shown, the test result is: 3482cm -1 It is the stretching vibration peak of O-H bond, 2830~2950cm -1 It is the stretching vibration peak of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com