Pit mud microorganism separation method

A separation method and microbial technology, applied in the field of microbial separation, can solve the problems of cumbersome operation, clean screening, and low efficiency, and achieve the effects of improving separation efficiency, preventing hyphae from balling, and accelerating the proliferation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

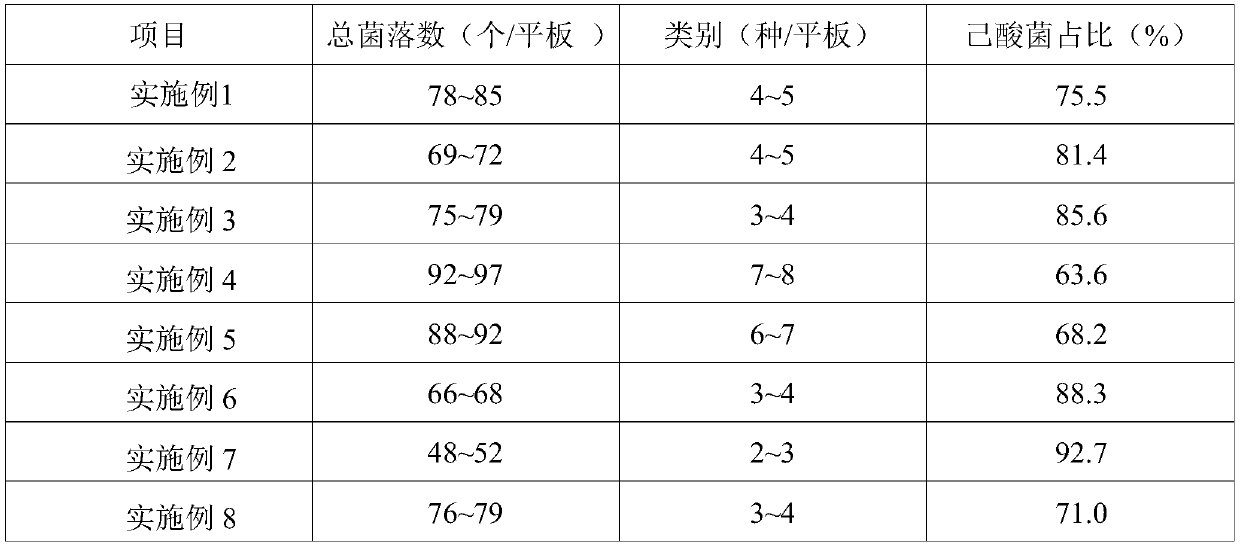

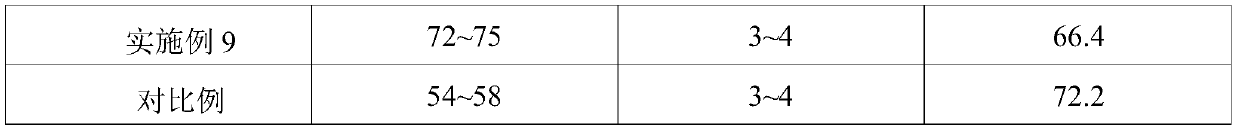

Examples

Embodiment 1

[0022] Step ①: Collect the pit mud in the cellar pool of the ancient Xiangyang winery in Hubei Province with the five-point sampling method, quickly put the collected pit mud into an anaerobic bag, put it on ice and transport it to the laboratory;

[0023] Step ②: Weigh 10g of the pit mud sample, add it into a triangular flask filled with sterile water and glass beads, and vibrate in a rotary shaker to obtain a pit mud suspension;

[0024] Step ③: The pit mud suspension is heated in a water bath at 80°C for 10 minutes to kill the vegetative cells, and then inoculated in the enrichment medium, which is distiller's lees infusion medium, and the components contained are calculated as : 1000 parts of distiller's grain extract, 50 parts of loess, 10 parts of yeast extract, 5 parts of NaAc, 10 parts of ethanol, MgSO 4 ·7H 2 O 0.3 parts, CaCO 3 5 parts, 10 parts of polyglutamic acid, 5 parts of sucrose ester, 37 ° C enrichment culture for 6 days, select the enrichment medium with e...

Embodiment 2

[0029] Embodiment 2 differs from Embodiment 1 in that:

[0030] Distiller's grain extract medium, the components contained in parts by mass are: 1000 parts of distiller's grain extract, 150 parts of loess, 10 parts of yeast extract, 3 parts of NaAc, 20 parts of ethanol, MgSO 4 ·7H 2 O 0.1 part, CaCO 3 5 parts, 20 parts of polyglutamic acid, 10 parts of sucrose ester, 37 ° C enrichment culture for 4 days.

Embodiment 3

[0032] Embodiment 3 differs from Embodiment 1 in that:

[0033] Distiller's grain extract medium, the components contained in parts by mass are: 1000 parts of distiller's grain extract, 50 parts of loess, 10 parts of yeast extract, 5 parts of NaAc, 10 parts of ethanol, MgSO 4 ·7H 2 O 0.3 parts, CaCO 3 5 parts, 30 parts of polyglutamic acid and 15 parts of sucrose ester were enriched and cultured at 37°C for 4 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com