Thermosensitive positive CTP plate developing solution

A heat-sensitive positive image and developing solution technology, which is applied in the field of developing solution, can solve the problems of developing crystals and developing sediments, and achieve the effects of reducing corrosion, reducing developing crystals and reducing developing sediments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

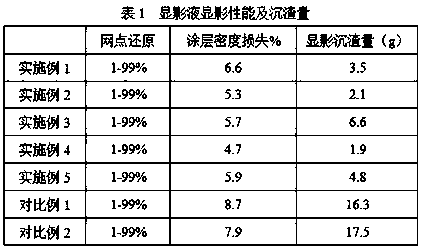

Examples

example

[0016] A thermal positive CTP plate developer, comprising the following components by weight: 8-14% of alkaline developer main agent, 2-8% of developer penetrant, 0.5-3% of coating protection agent, scale inhibitor 0.01-1% solvent, 0.1-5% organic solvent, 100% deionized water, scale inhibitors include benzotriazole sodium, benzotriazole, mercaptobenzothiazole, mercaptobenzothiazole sodium, methyl One or more of benzotriazoles.

[0017] The main alkaline developer is one or more of alkali metal hydroxides, alkali metal silicates, alkali metal phosphates, and alkali metal carbonates.

[0018] The alkali metal hydroxide is preferably sodium hydroxide, potassium hydroxide, lithium hydroxide; the alkali metal silicate is preferably sodium metasilicate, potassium metasilicate; the alkali metal phosphate is preferably sodium phosphate, disodium hydrogen phosphate, Sodium dihydrogen phosphate, potassium phosphate, dipotassium hydrogen phosphate, potassium dihydrogen phosphate; the al...

Embodiment 1

[0027] Add 820 liters of deionized water to the reactor equipped with a stirrer, and start stirring; add 120 kg of sodium metasilicate pentahydrate, and stir until completely dissolved; add 50 kg of sodium dodecylbenzene sulfonate, and stir until completely dissolved Add 10 kg of glycerin and stir until completely dissolved; add 0.2 kg of tolyltriazole and stir until completely dissolved; add 2.5 kg of sodium polyacrylate and stir until completely dissolved; add 10 kg of ethylene glycol monoethyl ether and stir until Completely dissolved to obtain a coating solution.

Embodiment 2

[0029] Add 820 liters of deionized water to the reactor equipped with a stirrer, and start stirring; add 125 kg of sodium metasilicate pentahydrate, and stir until completely dissolved; add 50 kg of sodium dodecylbenzene sulfonate, and stir until completely dissolved Add 8 kilograms of polypropylene glycol, stir until fully dissolved; add 0.25 kilograms of mercaptobenzothiazole, stir until fully dissolved; add 2 kilograms of sodium polyacrylate, stir until completely dissolved; add 10 kilograms of isopropanol, stir until completely dissolved, and obtain Coating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com