Perovskite micro-ring resonator array, preparation method and application thereof

A microring resonator and perovskite technology, which is applied in chemical instruments and methods, optical resonant cavity structures, instruments, etc., can solve the difficult to achieve size controllability and shape designability of perovskite microring resonators Problems such as difficulty in the positional accuracy of the microring resonator, to achieve the effect of easy batch preparation and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

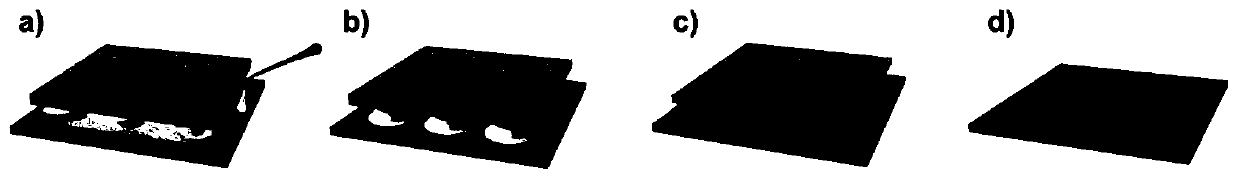

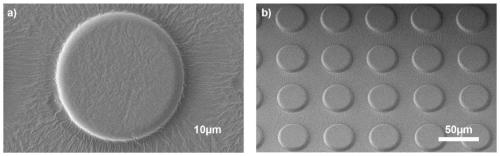

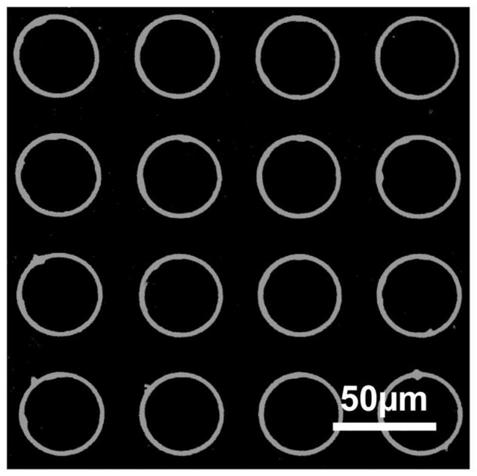

[0033] A method for preparing a perovskite microring resonator array, by adding perovskite MAPbBr 3 The precursor solution is confined between the template and the substrate, and the evaporation of the solvent is promoted by heating, so that the solution shrinks to the junction of the template micro-column structure and the substrate, forming a ring of high-concentration precursor solution around the micro-column. When the concentration reaches a After a certain value, crystallization begins around the micro-column to form a ring-shaped crystal, and the micro-ring resonator array conforming to the structure of the template is obtained after the template is removed.

[0034] A perovskite microring resonator array, the specific steps are as follows:

[0035] (1), the preparation of the template;

[0036] The specific steps are as follows: use photolithography to prepare the master template: firstly, a silicon wafer with a size of 25×25 mm and a thickness of 1 mm is ultrasonicat...

Embodiment 2

[0049] Based on MAPbBr 3 Microring resonators are used in laser resonators.

[0050] A perovskite microring resonator array has the characteristics of designable size and shape, simple preparation process and short time consumption, and has the advantage of complete shape, and can be used as a resonator in laser equipment. Since the obtained MAPbBr 3 Microrings are crystals that have very good light-emitting properties and thus act as a gain medium as well as a resonator. Under the action of a certain pump light, the microring resonator confines light of different specific wavelengths in the ring and amplifies the output to realize laser emission.

[0051] A perovskite microring resonator array is used as a microring resonator laser, and the specific steps are as follows:

[0052] Steps (1), (2), (3) are the same as in Example 1.

[0053] (4), preparation of microring resonator laser: MAPbBr obtained through steps (1), (2), (3) 3 Microring resonator arrays are directly us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com