System and method for treating black and odorous water bottom sludge in rural areas

A black and odorous water body and treatment system technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve problems such as air and environmental pollution, virus transmission, soil waste, etc., and achieve improved fermentation Quality and efficiency, solve the shortage of fermentation bacteria, and ensure the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

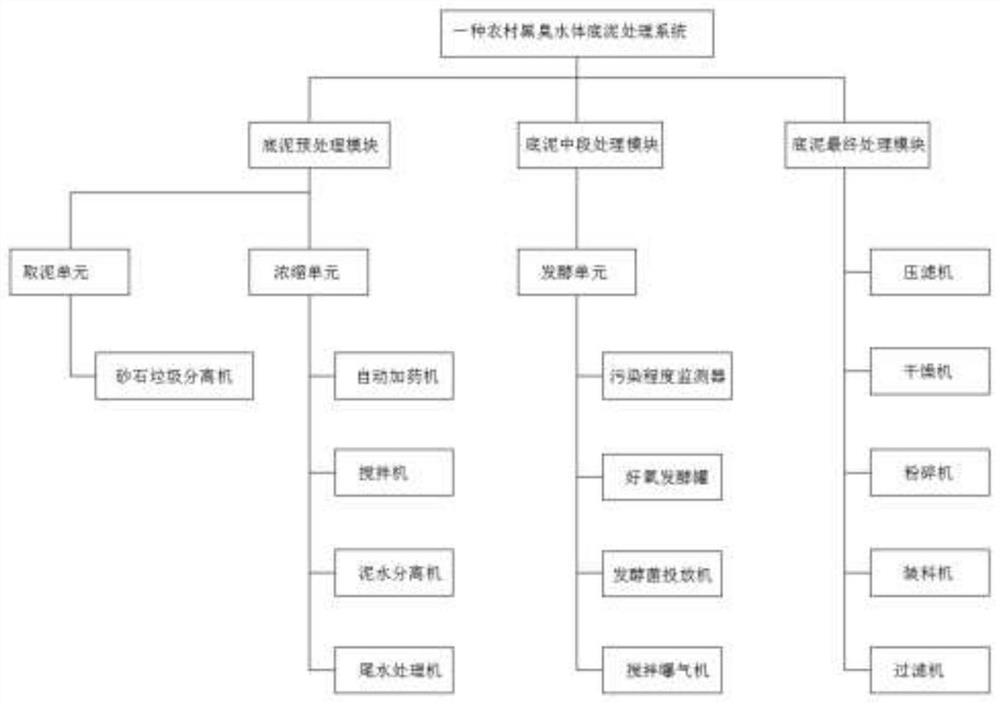

[0030] As shown in Question 1, a sediment treatment system for black and odorous water bodies in rural areas includes: a sediment pretreatment module, a middle sediment treatment module, and a final sediment treatment module in the order of processes;

[0031] The sediment pretreatment module includes: a mud extraction unit for dredging the sediment in the black and odorous water body and a concentration unit for concentrating the dredged sediment and removing water.

[0032] The mud extraction unit includes a sand and gravel garbage separator that can separate sand and gravel garbage and bottom mud in the river. The sand and gravel garbage separator is purchased from a vibrating sand and gravel separator from Weifang Zhongwei Environmental Protection Technology Co., Ltd. The concentration unit includes in sequence from the process: an automatic flocculant dosing machine purchased from Guangzhou Jindian Environmental Protection Engineering Co., Ltd., which can solidify and prec...

Embodiment 2

[0041] Described embodiment 2 differs from embodiment 1 in that:

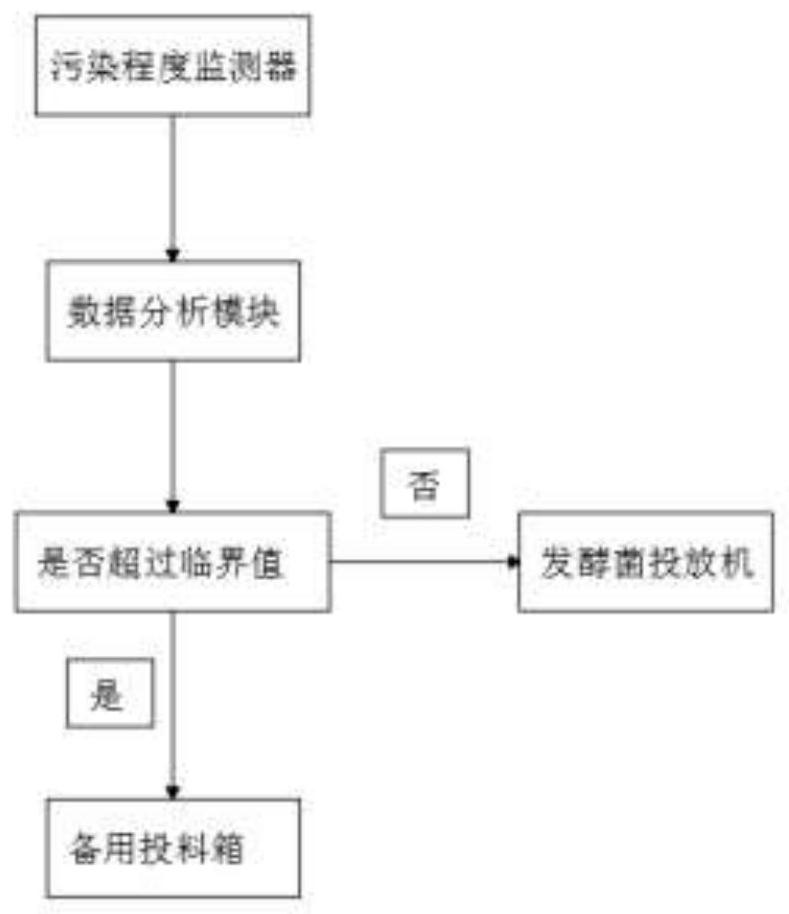

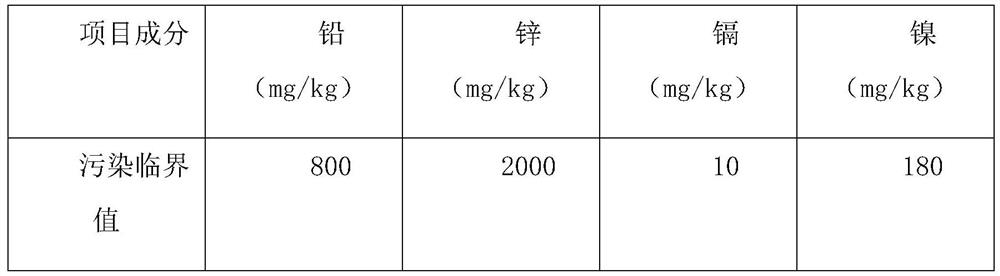

[0042] Such as figure 2 As shown, the data analysis module is set on the pollution degree monitor, and the pollution degree critical value is set. After the data analysis module analyzes the detected data, it is judged whether to operate the spare feeding box for feeding. The critical value setting As shown in Table 1.

[0043] Table 1: Critical values of sediment pollution components

[0044]

[0045] Where the critical value exceeds 1%, the spare feeding box will add 8% of the fermented bacteria to be put in, and the fermented bacteria used in the spare feeding box will increase the component concentration by 5% compared with the fermented bacteria in the fermented bacteria feeding machine.

[0046] The data analysis module is a 51 single-chip microcomputer. After the single-chip microcomputer processes the data, the solenoid valve on the standby feeding machine is operated through a relay to inject m...

Embodiment 3

[0048] Described embodiment 3 differs from embodiment 1 in that:

[0049] The automatic dosing machine is also provided with a composite conditioner for conditioning and tempering the bottom mud. The composite conditioner includes the following components in terms of mass percentage: 50% of asbestos-free microporous calcium silicate powder, 40% of the gel wrapping agent, and the balance is polyaluminum iron silicate; wherein, the preparation method of the gel wrapping agent is: 12g of nano-active carbon powder and 500ml of water are configured into a suspension, and then sequentially added polyacrylamide 120g, ammonium persulfate 18g, carboxymethyl chitosan 20g, after stirring and aging at room temperature for 0.5h, let it stand for 18h to obtain a gel-like product, and granulate and dry at 40°C to make gel particles. It is the gel wrapping agent, and the particle size of the asbestos-free microporous calcium silicate powder is 1-2000 microns.

[0050] Add above-mentioned com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com