End-capped multipurpose antibacterial organic silicon resin and preparation method thereof

A silicone, multi-purpose technology, applied in the field of end-capped multi-purpose antibacterial silicone resin and its preparation, can solve the problems of loss of mechanical properties, weather resistance, poor life, damage, etc., to ensure isotropy, good The effect of surface activity and dispersibility, biodegradation resistance and heat aging resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

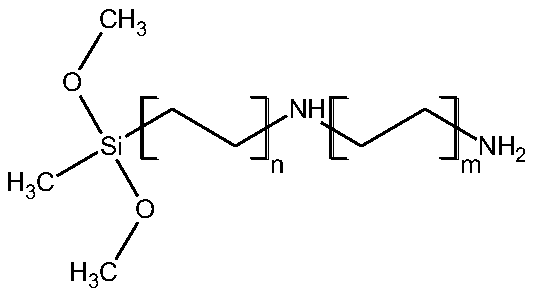

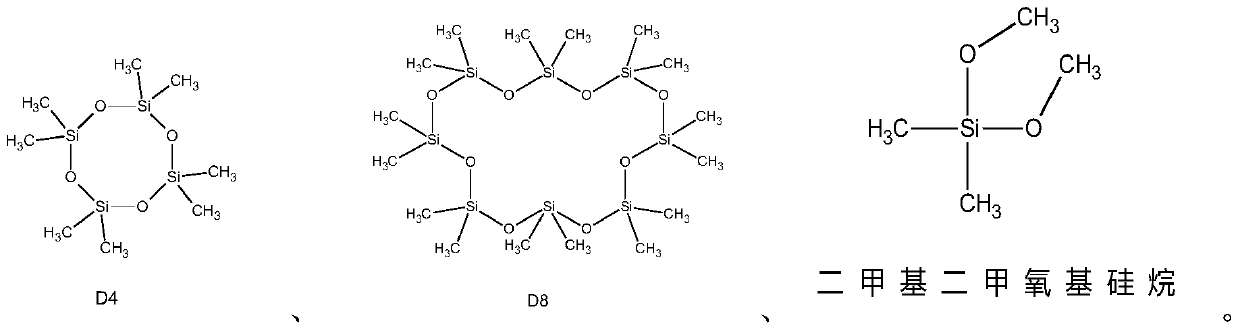

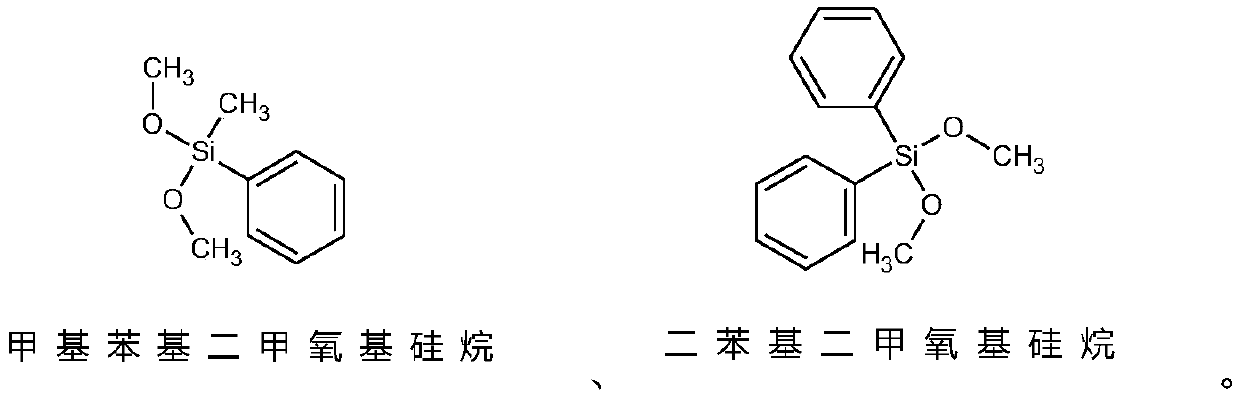

[0039] First, the flexible monomer and the rigid monomer are added into the three-necked flask in a ratio of 4:6 (mass parts) with a total mass of 80 parts, the sealing device is filled with nitrogen and heating is started, and then the mass of aminosilane (n=1, m=1) is added Part 10 and sodium bicarbonate solution concentration 20% mass part 10, heat up to 80-86 degrees Celsius, react for 4 hours (at this time the monomer conversion rate reaches about 85%), viscosity 1200mPa.s ~ 1400mPa.s, add acetic acid to neutralize to The pH value is 6.8-7; the low-boiler is distilled off after vacuum distillation for 2-2.5 hours, and a transparent and viscous end-capped multi-purpose silicone resin is obtained. Stop stirring and cool down to 25°C, weigh. Based on the weighed value, add absolute ethanol into three ports according to the ratio of end-capping multi-purpose silicone resin: alkylation reagent W: absolute ethanol = 60:10:30 Start the agitator in the flask, slowly raise the tem...

Embodiment 2~6

[0041] Compared with Example 1, only the ratios of flexible monomers to rigid monomers and flexible monomers to rigid monomers were changed.

[0042] Table 1 Embodiment 2~6 flexible monomer and rigid monomer ratio value

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com