Nucleating agent for polylactic acid, composition and preparation method of nucleating agent

A technology of nucleating agent and polylactic acid, which is applied in the field of preparation of nucleating agent, composition and nucleating agent for polylactic acid, can solve the problems that have not been reported, and achieve the improvement of crystallinity and Vicat softening temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051]

[0052] The preparation method of nucleating agent of the present invention comprises the steps:

[0053] The alcohol solution containing the water-soluble rare earth salt is reacted with the aqueous solution of the alkali metal aryl phosphate containing the amino group, filtered to obtain a filter cake, and the filter cake is dried to obtain the rare earth aryl phosphate containing the amino group.

[0054] In some embodiments, it also includes mixing amino group-containing rare earth aryl phosphate with inorganic powder, antioxidant and plasticizer to obtain a nucleating agent.

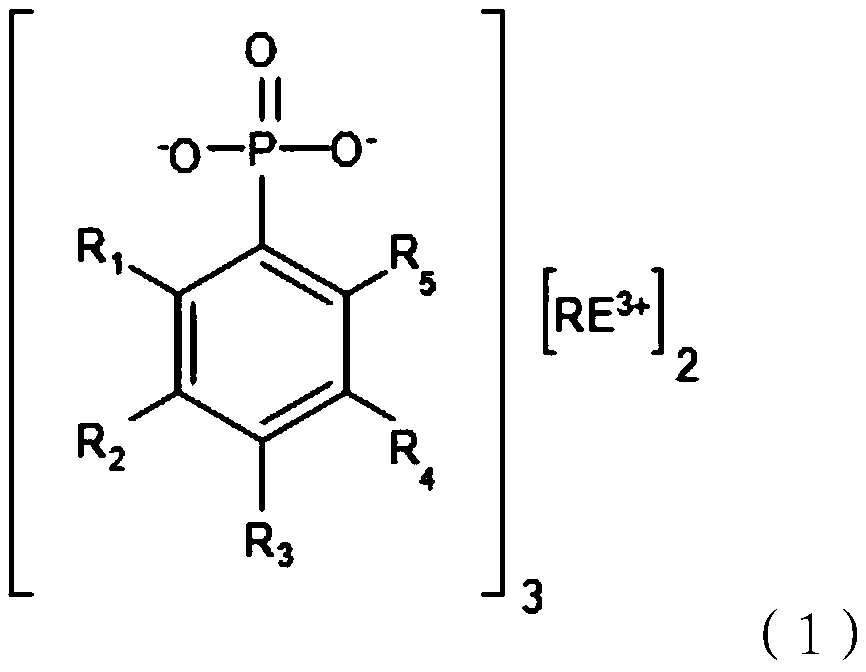

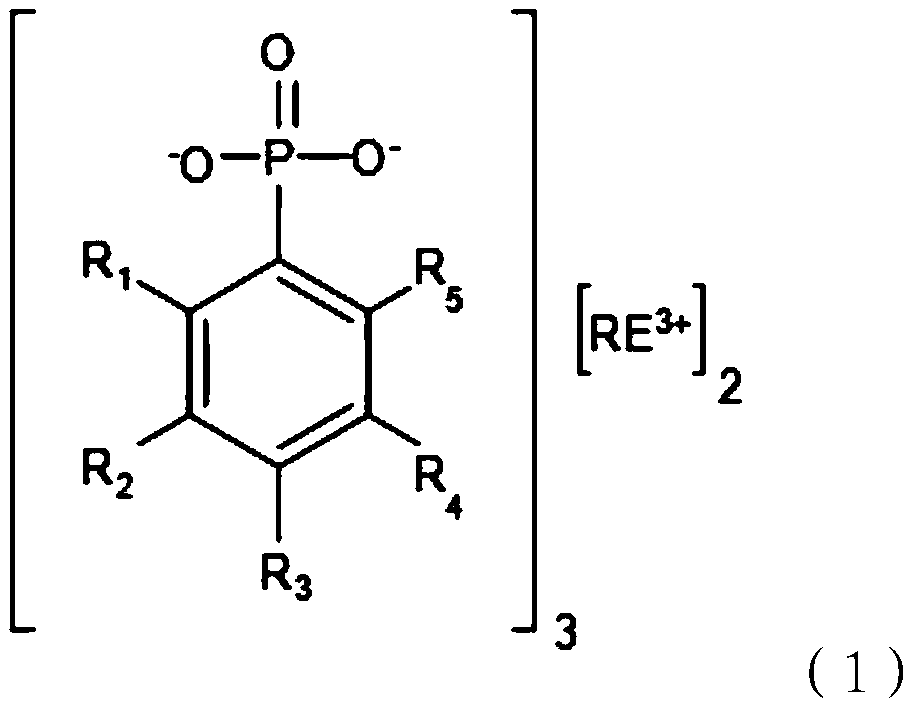

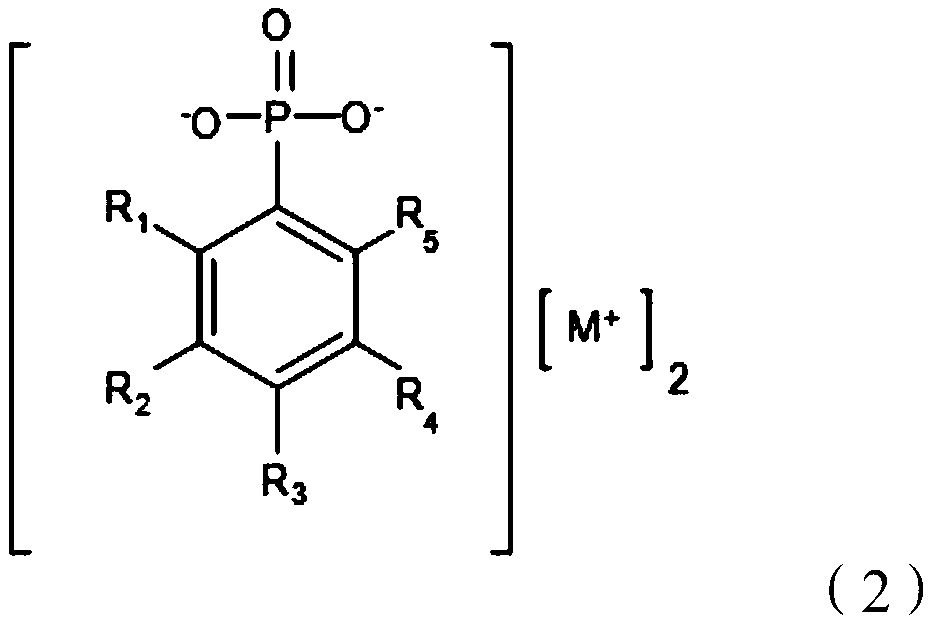

[0055] Amino group-containing alkali metal aryl phosphate of the present invention has the structure shown in formula (2)

[0056]

[0057] In formula (2), R 1 , R 5 are independently selected from hydrogen atom, C1~C3 alkyl; R 2 , R 3 and R 4 are independently selected from a hydrogen atom, an amino group, a C1-C8 alkyl group, and R 2 , R 3 and R 4 At least one of them is amino...

Embodiment 1

[0084] The nucleating agent comprises: 30 parts by weight of cerium p-aminophenyl phosphate, 15 parts by weight of silanized montmorillonite (inorganic powder, particle diameter of 5 μm), 25 parts by weight of antioxidant 1076, and acetyl tributyl citrate (plasticizer) 30 parts by weight.

[0085] The preparation method of nucleating agent comprises the steps:

[0086] Add the ethanol solution (concentration: 0.55mol / L) containing cerium chloride dropwise to the aqueous solution of sodium p-aminophenylphosphate (concentration: 2.4mol / L) at a rate of 10ml / min, and at 50°C React until no precipitate is formed, filter to obtain a filter cake, wash the filter cake with absolute ethanol and dry the filter cake at 80°C for 12 hours to obtain cerium p-aminophenylphosphate;

[0087] The cerium p-aminophenylphosphate, silylated montmorillonite, antioxidant 1076 and acetyl tributyl citrate (plasticizer) are uniformly mixed according to the above ratio to obtain a nucleating agent.

Embodiment 2

[0089] The nucleating agent comprises: 50 parts by weight of cerium p-aminophenylphosphate, 10 parts by weight of silylated nano silicon dioxide (inorganic powder, particle diameter is 800nm), 15 parts by weight of antioxidant 1010, and tributyl acetyl citrate 25 parts by weight of ester (plasticizer).

[0090] The preparation method of nucleating agent comprises the steps:

[0091] Add the ethanol solution (concentration: 0.55mol / L) containing cerium chloride dropwise to the aqueous solution (concentration: 1.2mol / L) of sodium p-aminophenylphosphate at a rate of 30ml / min, and react at 60°C Until no precipitate is formed, filter to obtain a filter cake, wash the filter cake with absolute ethanol and dry the filter cake at 80°C for 12 hours to obtain cerium p-aminophenylphosphate;

[0092] Mix cerium p-aminophenylphosphate, silanized nano silicon dioxide, antioxidant 1010 and acetyl tributyl citrate uniformly according to the above ratio to obtain a nucleating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com