A kind of molybdenum aluminum molybdenum and ito/ag/ito compatible etching solution and preparation method

A technology compatible with etching and etching solution, applied in the field of etching solution, can solve the problems of silver layer shrinkage, waste, time-consuming materials, etc., and achieve the effect of smooth side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

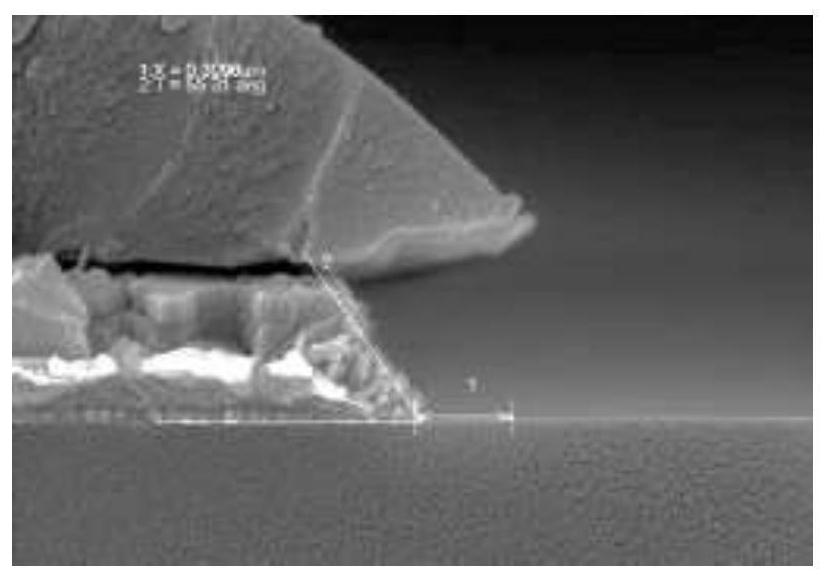

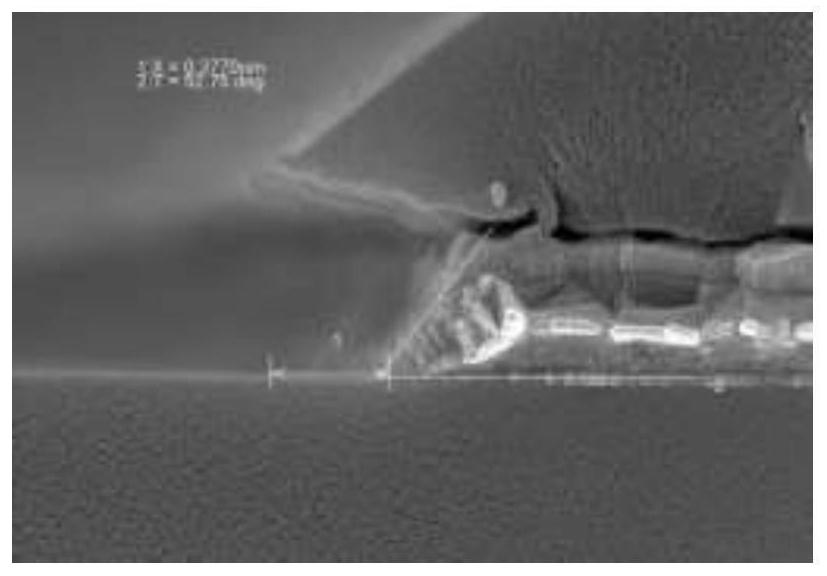

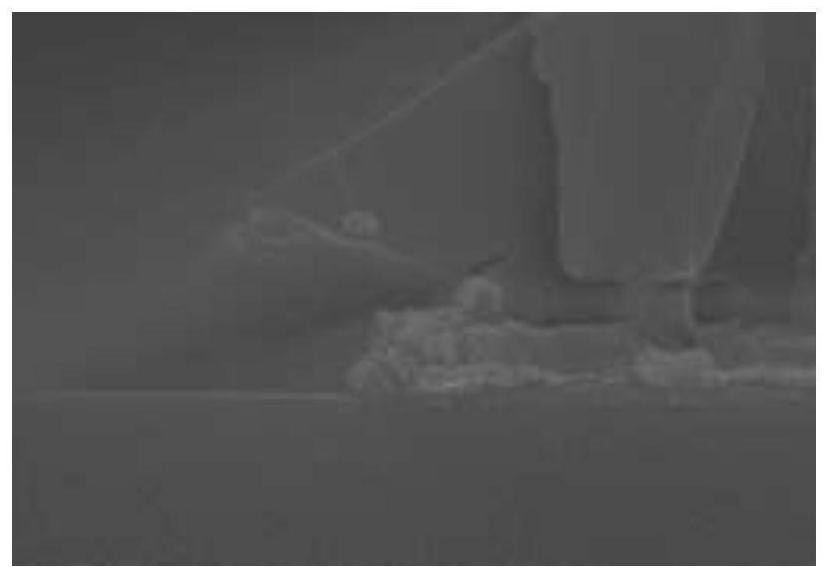

Image

Examples

Embodiment 1

[0030] Prepare etchant:

[0031] The first step: Weigh by weight percentage, phosphoric acid 65%, nitric acid 5%, acetic acid 20%, monolauryl phosphate 2%, hydroxyethylidene diphosphonic acid 0.5%, compound metal inhibitor 0.5%, wherein molybdenum 0.1% sodium nitrate, 0.1% potassium nitrate, 0.1% mercaptobenzothiazole, 0.1% lauric acid, 0.1% mercaptobenzothiazole, and the rest of water.

[0032] Step 2: Take 1 / 3 of the required pure water, add the weighed molybdate, nitrate, mercaptobenzothiazole, lauric acid and mercaptobenzothiazole into the water in turn, mix and stir, and disperse evenly by ultrasonic oscillation.

[0033] Step 3: Add 1 / 3 of the required amount of pure water to the batching tank, add the required amount of nitric acid under stirring, and mix evenly; 1 / 3 pure water, stir well;

[0034] Step 4: Add lauryl phosphate, hydroxyethylidene diphosphonic acid and the prepared compound metal inhibitor to the mixture obtained in the third step, and stir thoroughly; ...

Embodiment 2

[0037]Preparation of etching solution: Prepare etching solution according to the formula and method of Example 1. The difference from Example 1 is that the compound metal inhibitor is 1.0%, wherein sodium molybdate is 0.2%, potassium nitrate is 0.2%, and mercaptobenzothiazole is 0.2%. %, lauric acid 0.2% and mercaptan benzothiazole 0.2%.

Embodiment 3

[0039] Preparation of etching solution: Prepare etching solution according to the formula and method of Example 1. The difference from Example 1 is that the compound metal inhibitor is 1.5%, wherein sodium molybdate is 0.3%, potassium nitrate is 0.3%, and mercaptobenzothiazole is 0.3%. %, lauric acid 0.3% and mercaptan benzothiazole 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com