Tin-based metal-organic framework and preparation method thereof, and application of tin-based metal-organic framework as lithium ion battery negative electrode material

A technology of lithium-ion batteries and organic frameworks, applied in battery electrodes, secondary batteries, circuits, etc., to achieve performance improvement, alleviate volume expansion effects, and promote research progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Take by weighing stannous sulfate SnSO 4 (0.4mmol, 85.6mg) and 2,5-dihydroxyphthalic acid (0.2mmol, 54.8mg) mixture into a glass bottle, followed by adding 25mL of distilled aqueous solution containing lithium hydroxide (0.8mmol, 32mg), stirring Obtain a uniform mixture;

[0030] 2) Place the uniformly mixed mixed solution in an oven at 80°C for 72 hours, and then cool it down to room temperature naturally to obtain light yellow flaky crystals;

[0031] 3) The obtained crystals were washed with distilled water and ethanol, and dried naturally to obtain a tin-based metal-organic framework.

Embodiment 2

[0033] 1) Take by weighing stannous sulfate SnSO 4 (0.4mmol, 85.6mg) and 2,5-dihydroxyphthalic acid (0.1mmol, 27.4mg) mixture into a glass bottle, followed by adding 15mL of distilled aqueous solution containing lithium hydroxide (0.6mmol, 24mg), stirring Obtain a uniform mixture;

[0034] 2) Place the uniformly mixed mixed solution in an oven at 85°C for 48 hours, and then cool it down to room temperature naturally to obtain light yellow flaky crystals;

[0035] 3) The obtained crystals were washed with distilled water and ethanol, and dried naturally.

Embodiment 3

[0037] 1) Take by weighing stannous sulfate SnSO 4 (0.3mmol, 64.2mg) and 2,5-dihydroxyphthalic acid (0.1mmol, 27.4mg) mixture into a glass bottle, then add 45mL distilled aqueous solution containing lithium hydroxide (0.5mmol, 20mg), Stir evenly to obtain a mixture;

[0038] 2) Place the uniformly mixed mixture in an oven at 95°C for 24 hours, and then cool it down to room temperature naturally to obtain light yellow flaky crystals;

[0039] 3) The obtained crystals were washed with distilled water and ethanol, and dried naturally.

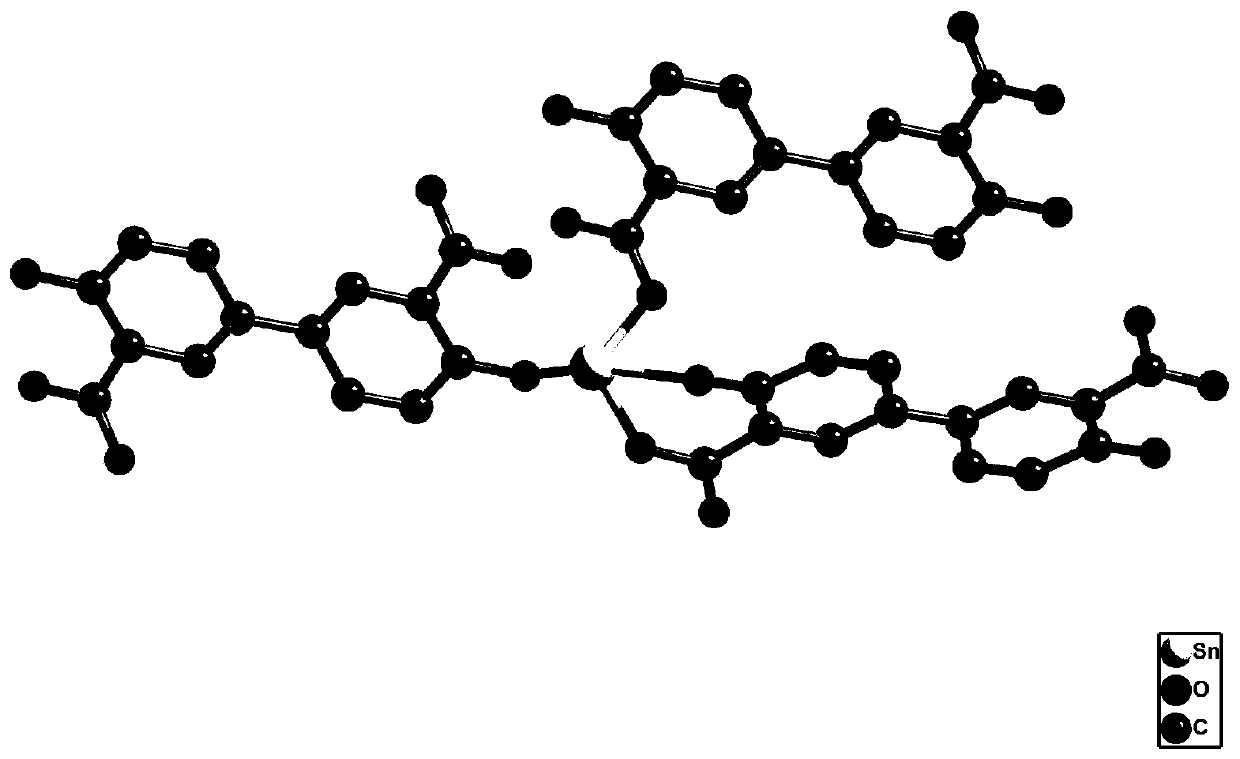

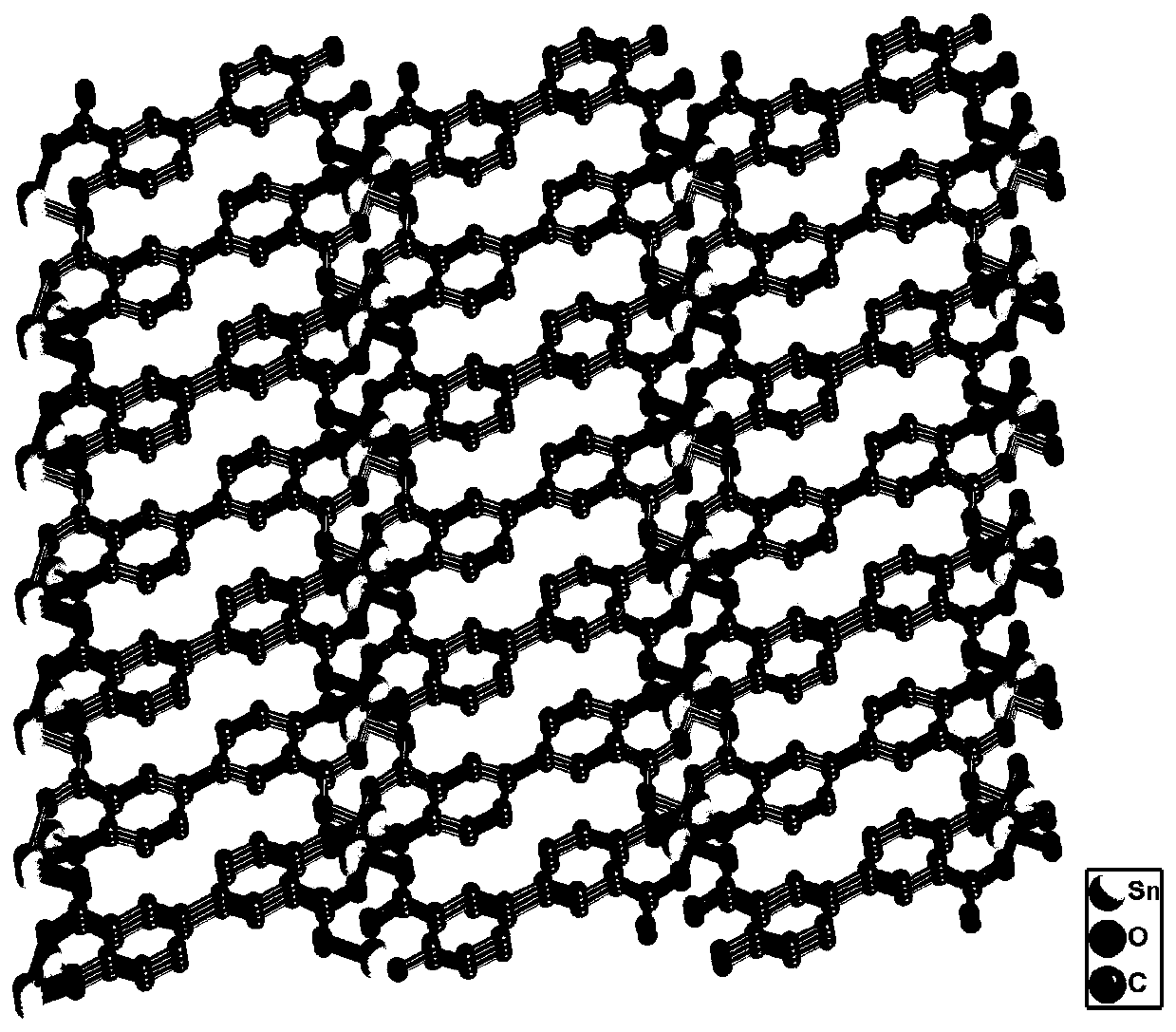

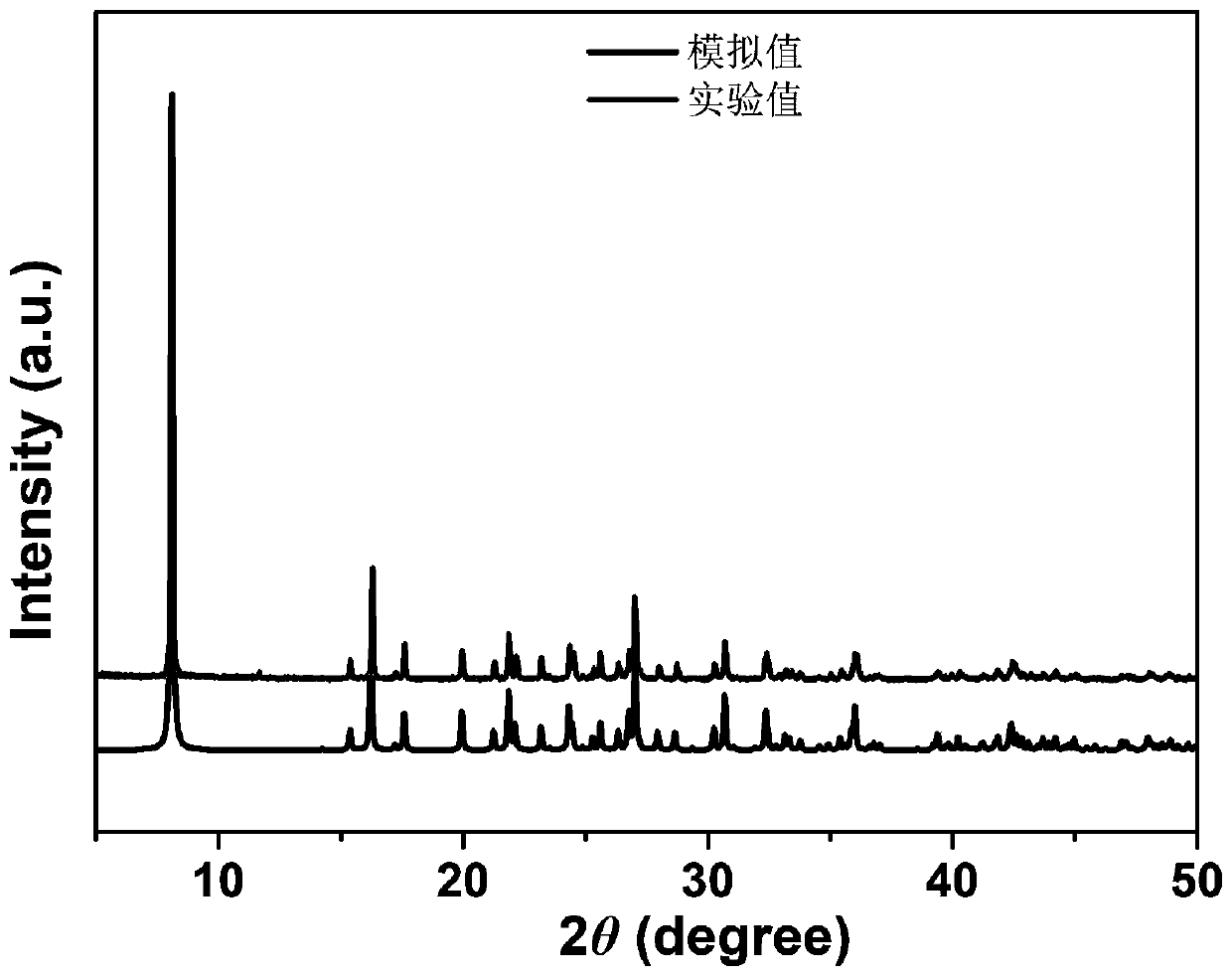

[0040] 2. Characterization of tin-based metal-organic frameworks

[0041] Get the crystals obtained in the above examples on a glass slide, select a suitable crystal under a microscope, test it on a Supernova type X-ray single crystal diffractometer, and use the Mo-Kα ray monochromatized by a graphite monochromator is the incident radiation source, with Diffraction points were collected by scanning, and their coordinates and anisotropy param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com