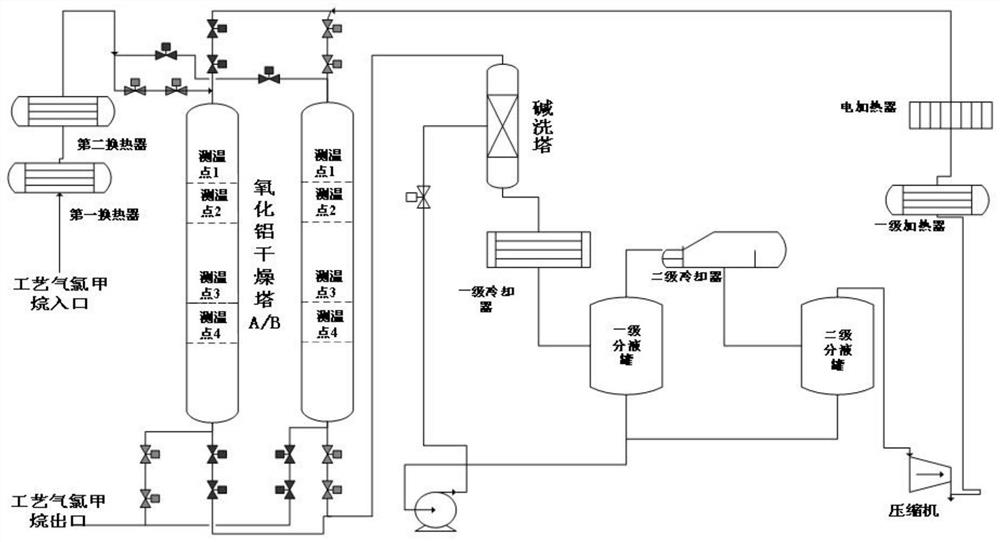

A kind of cyclic regeneration method of alumina drying tower in butyl rubber plant

A cyclic regeneration, butyl rubber technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of affecting the adjustment of polymerization reaction, unqualified Mooney viscosity of butyl rubber, and increase the energy consumption of butyl rubber equipment , material consumption and other issues, to achieve the effect of good interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

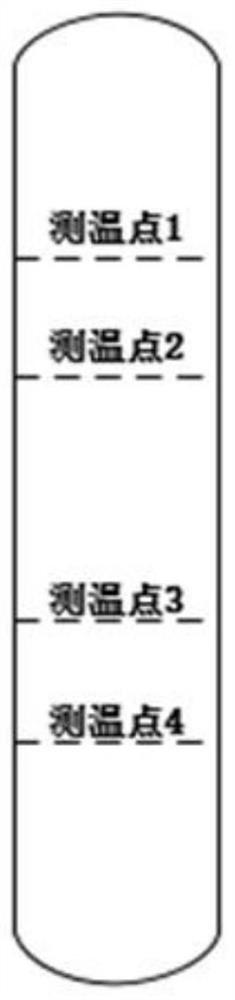

[0047] (1) When the DME in the bed layer of the alumina drying tower A tower is saturated (the DME content at the outlet of the alumina drying tower A tower is 6.96ppm), prepare to switch to the standby alumina drying tower B tower: first open the B tower to The valve to the torch line releases the nitrogen gas in the tower. When the pressure drops to 15KPa, close the valve to the torch line, open the process gas circulation methyl chloride to the inlet valve of tower B, and pass the process gas chloride to tower B of the spare alumina drying tower. Pressurize, and at the same time open the outlet of tower B to the flare line valve, and replace the residual nitrogen in the bed with process gas chloride, which is cooled to 22°C through a heat exchanger in advance; due to the adsorption of activated alumina A large amount of heat will be released, so the temperature of the bed of tower B will be raised in the above process. When the temperature measurement point at the bottom of ...

Embodiment 2~3

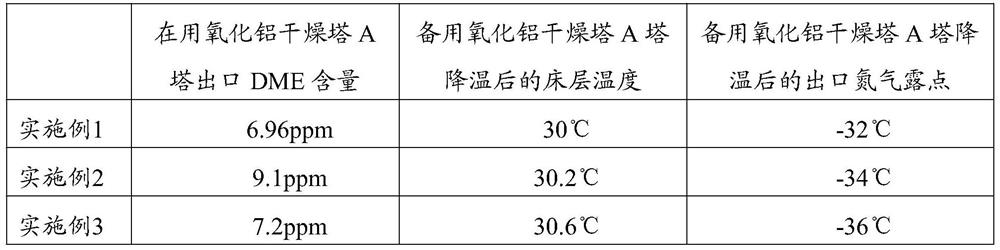

[0050]Adopt the recycling method of alumina drying tower in the butyl rubber plant that embodiment 1 provides, difference is: in step (1), use alumina drying tower A tower outlet DME content, step (2) standby alumina drying tower The bed temperature and outlet nitrogen dew point temperature after tower A cooling down; see Table 1 for details.

[0051] Table 1 Differences in the condition parameters of the cyclic regeneration method of the alumina drying tower in the butyl rubber plant provided by Examples 1 to 3 of the present invention

[0052]

[0053] Taking Example 1 as an example, the bed temperature rise data (DCS data statistics) during switching before and after improvement were compared. The results are shown in Tables 2-3.

[0054] Table 2 adopts the cycle regeneration method provided in Example 1 to improve the bed temperature rise data when switching

[0055]

[0056]

[0057] Table 3 Bed temperature rise data when switching after adopting the improved cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com