Petroleum fracturing propping agent production line and petroleum fracturing propping agent production process

A fracturing proppant and production line technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of large power consumption, affecting grading effect, and low processing capacity per unit area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

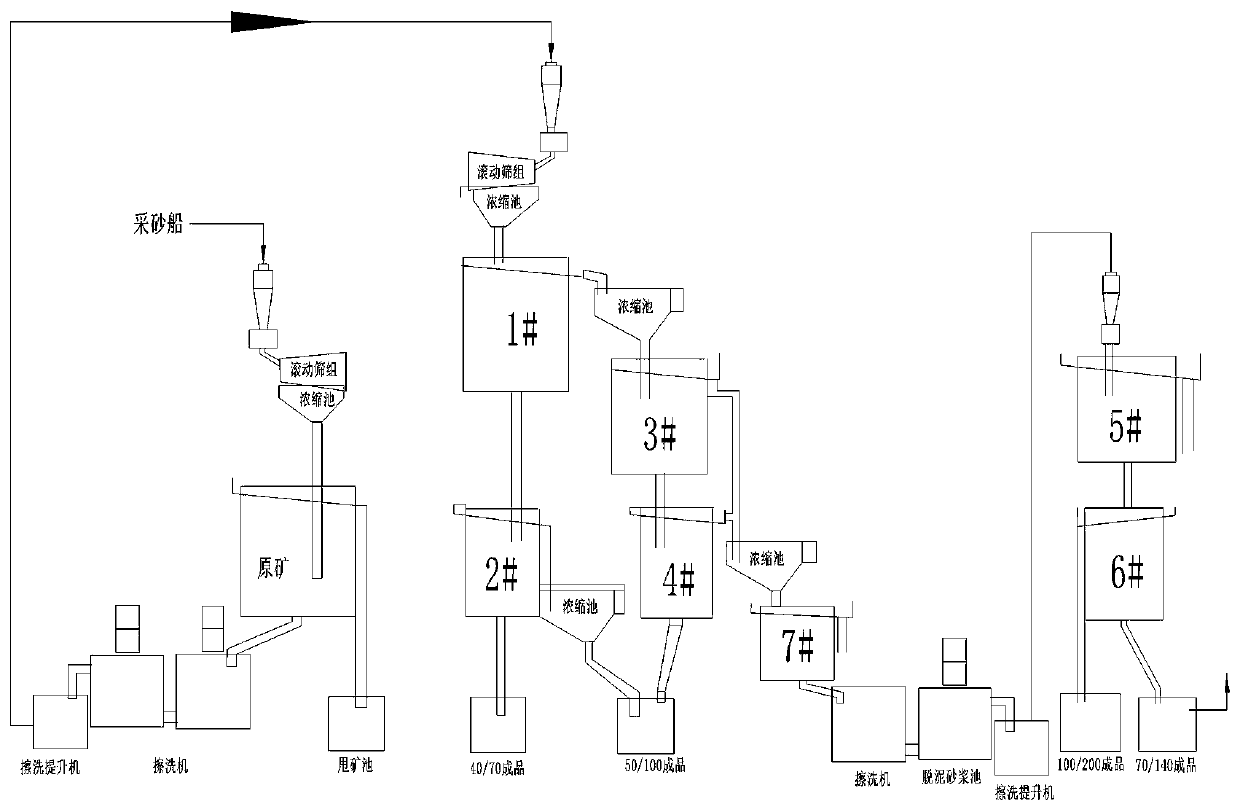

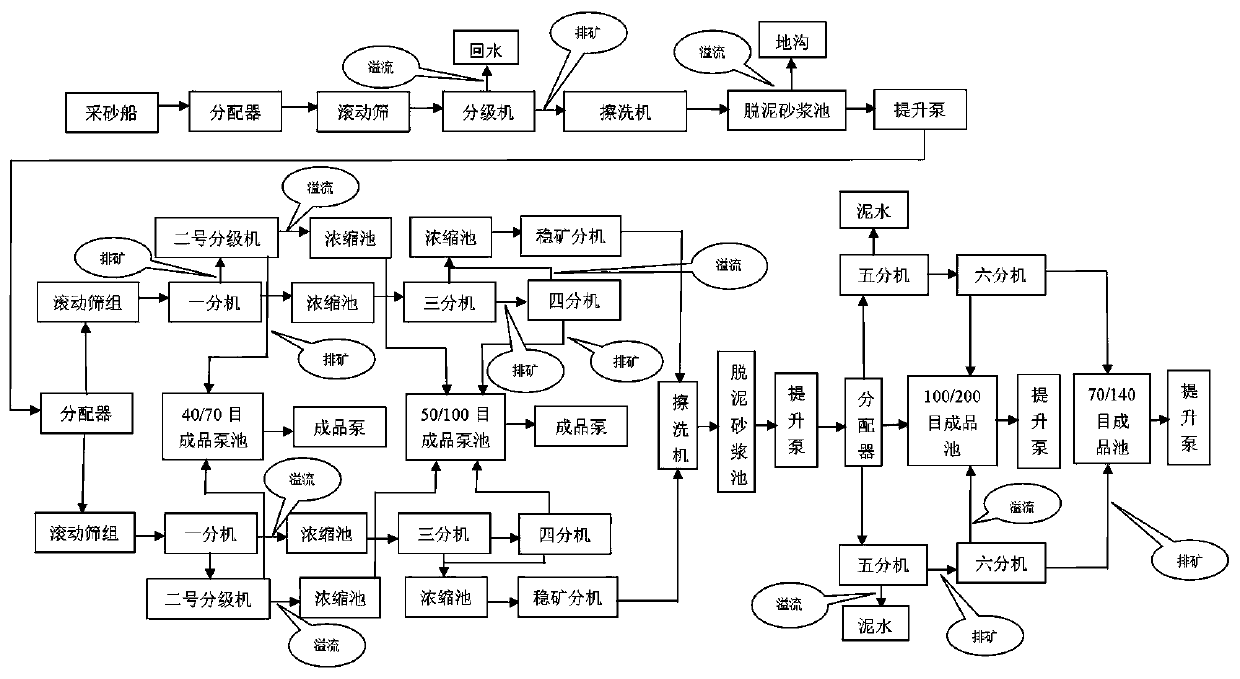

[0100] A petroleum fracturing proppant production line includes a feeding system, a pretreatment system, a primary sorting system, and a secondary sorting system. The feeding system is used to continuously supply mortar raw materials from The mortar raw materials supplied by the feeding system include but are not limited to dehydration, concentration, impurity removal, scrubbing, and lifting operations. The primary sorting system is used to sort the coarse products of the mortar processed by the pre-treatment system. The secondary sorting system It is used for fine product sorting of mortar after being sorted by a sorting system; the coarse product is a silica sand product with a mesh number in the range of 40-100, and the fine product is a silica sand product with a mesh number in the range of 70-200 Silica sand products within. The mortar refers to a mixture with water and sand as the main components, which may contain a small amount of impurities such as mud, dirt, and garb...

Embodiment 2

[0144] Such as figure 2 As shown, on the basis of the above-mentioned embodiments, the primary sorting system described in this embodiment is provided with two sets of parallel primary classifiers, and there are two sub-machines, two sub-machines, three sub-machines, and four sub-machines;

[0145] There is a first distributor between the two sub-machines and the second impurity screen. The first distributor has a three-way structure, and a mixing chamber is provided at the intersection of the three-way. The mixing chamber is used for mixing evenly by the first The impurity sieve enters the mortar of two one-extension machines;

[0146] The outlets of the two sub-units share the first product pool, the overflow outlets share the second product pool, and the outlets of the two four-unit machines share the second product pool.

[0147] The secondary sorting system is provided with two sets of parallel secondary classifiers, and the five-point machine and the six-point machine ...

Embodiment 3

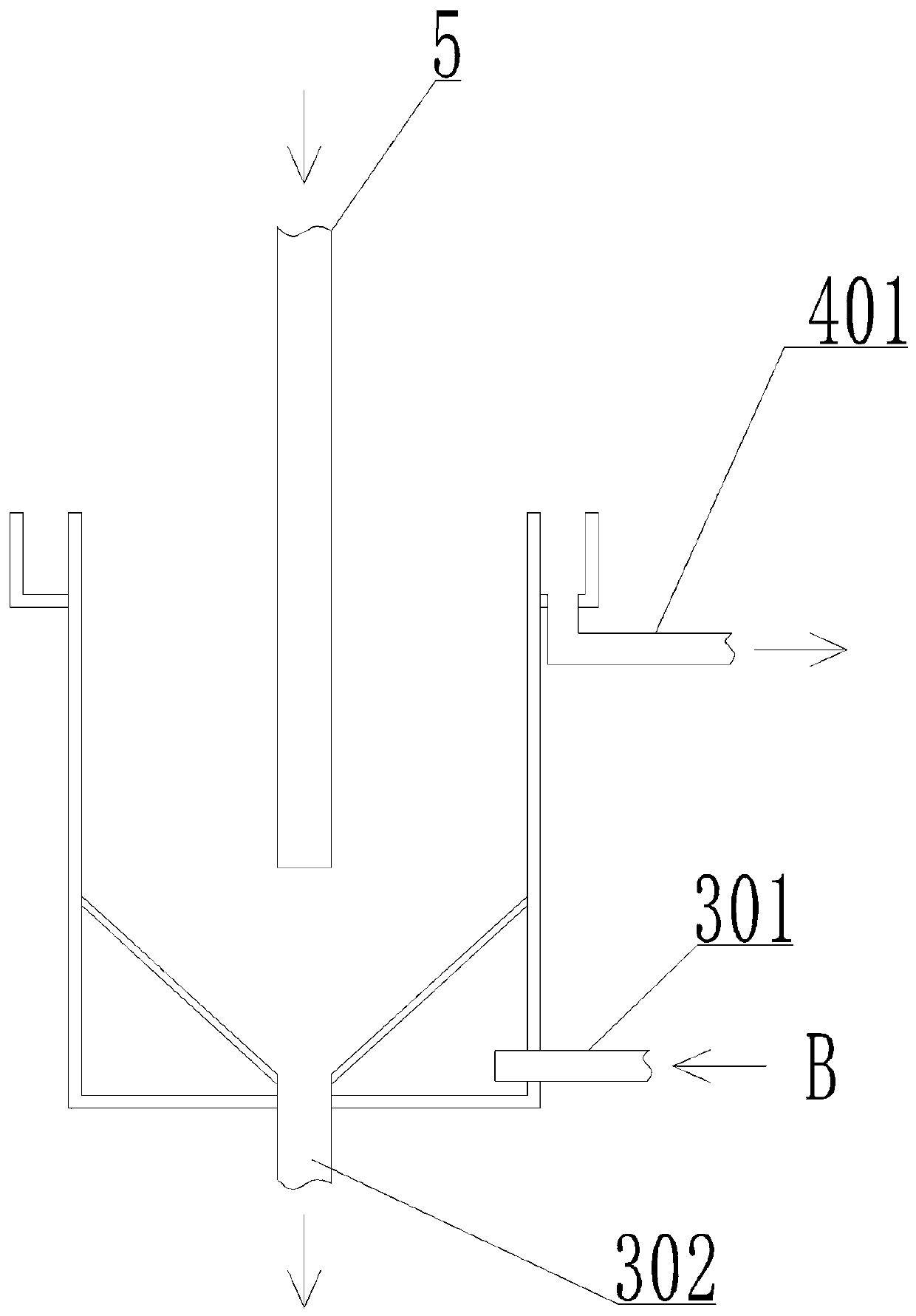

[0153] On the basis of the above-mentioned embodiments, the primary classifier described in this embodiment is shaped as a drum, and the bottom of the drum is provided with an inverted conical shell 1, such as Figure 4 As shown, a plurality of water inlet holes 101 are annularly distributed on the side of the conical shell 1, so that the annularly distributed water inlet holes 101 have multiple layers, and the upper edge of the conical shell 1 is welded together with the inner surface of the drum. The lower edge is welded to the bottom surface of the drum, and the drum is divided into upper and lower cavities by the conical shell 1, the upper cavity is the settlement space 2, the lower cavity is the water inlet space 3, and the side of the water inlet space 3 is A water inlet pipe 301 is provided on the wall; a discharge port 302 is provided below the conical shell 1; the discharge port 302 is connected with the bottom surface of the drum, and a valve is provided in the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com