Organic-inorganic hybrid perovskite and preparation method and application thereof

A perovskite material and inorganic technology, applied in the field of perovskite material preparation, can solve the problems of lack of mechanical stability and thermal stability, photoelectric function needs to be improved, etc., to achieve easy photoelectric functionality, good semiconductor performance, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example discloses an implementation of an organic-inorganic perovskite, specifically shown in the following reaction formula:

[0042]

[0043] The specific operation is: dissolve 0.436 g of antimony trioxide solid in 5 mL of acetonitrile at room temperature, stir, and dropwise add concentrated hydrochloric acid with a mass fraction of 36% with a dropper until the solution is clear to obtain a colorless and clear solution I;

[0044] Dissolve 0.246 g of 3-hydroxypyrrolidine hydrochloride in 5 mL of acetonitrile at room temperature to obtain a colorless and clear solution II;

[0045] Add the solution II into the solution I, continue to stir and react for half an hour, filter, put the obtained solution in an oven at 60°C for 48 hours, and finally obtain the following: figure 1 The colorless rod-shaped crystal shown is an organic-inorganic hybrid perovskite material, as shown in Formula 1.

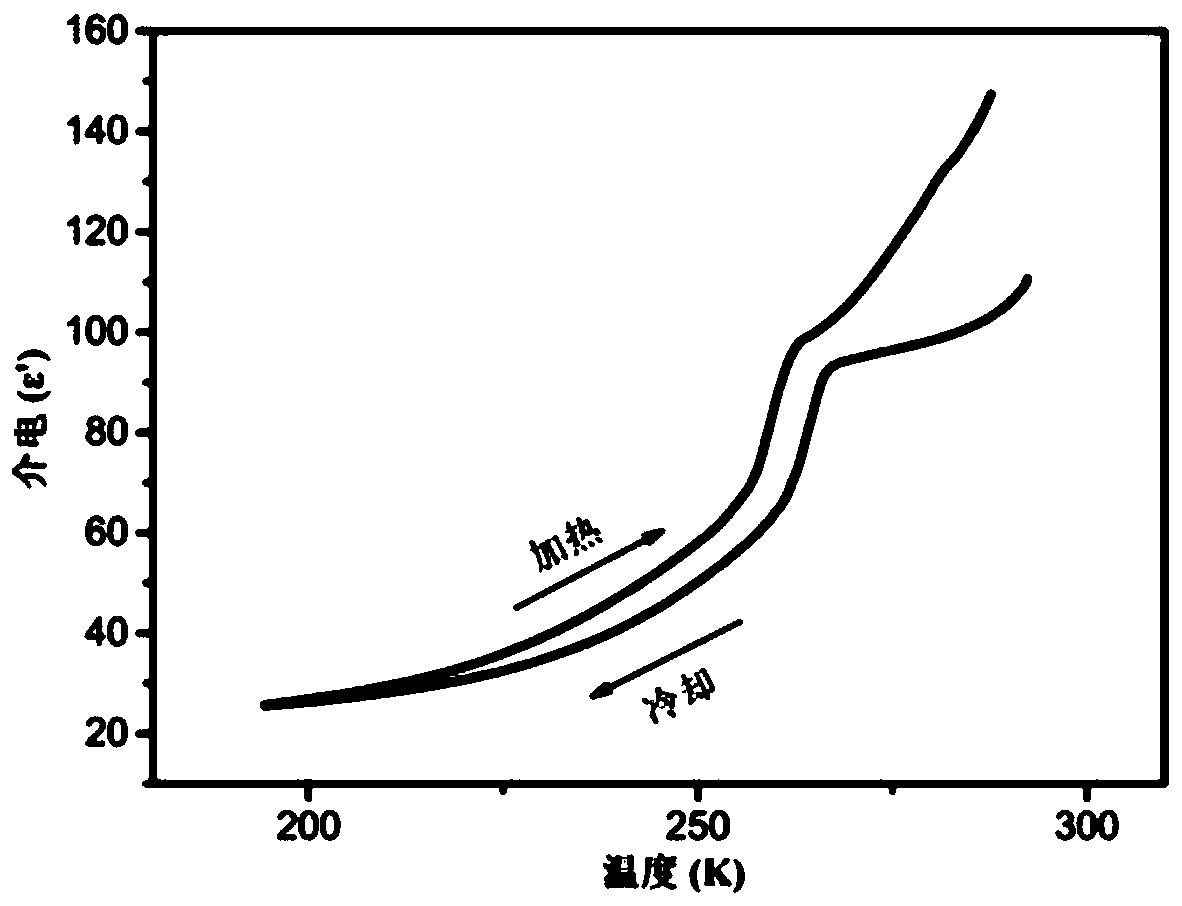

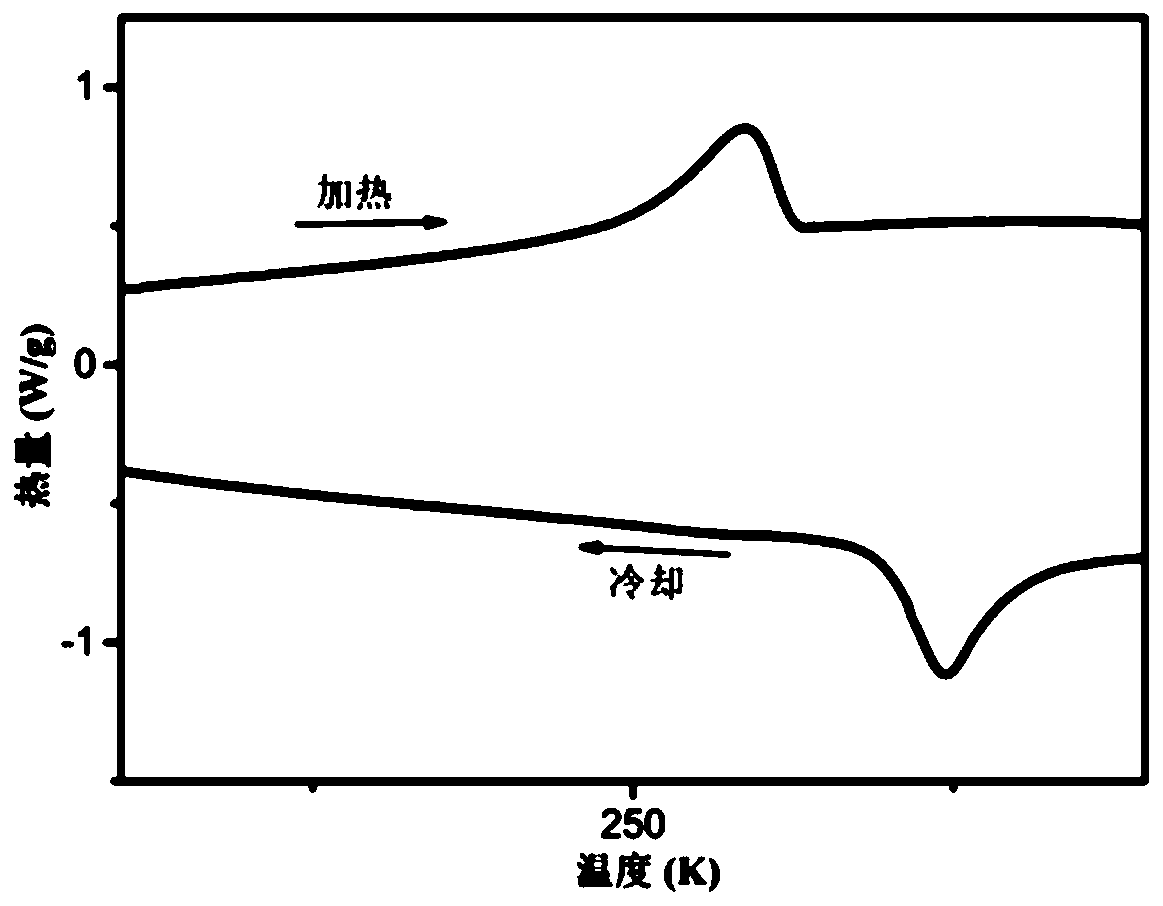

[0046] figure 2 It is the dielectric diagram of the perovskite materia...

Embodiment 2

[0052] This example discloses an implementation of an organic-inorganic perovskite, specifically shown in the following reaction formula:

[0053]

[0054] The specific operation is to dissolve 0.457 g of cadmium chloride solid in 5 mL of methanol at room temperature, stir, and dropwise add concentrated hydrochloric acid with a mass fraction of 38% with a dropper to obtain a colorless and clear solution I;

[0055] Dissolve 0.246 g of 3-hydroxypyrrolidine hydrochloride in 5 mL of methanol at room temperature to obtain a colorless and clear solution II;

[0056] Add the solution II into the solution I, continue to stir and react for half an hour, filter, put the obtained solution in an oven at 60°C for 24 hours, and finally obtain the following: Figure 7 The colorless blocky crystal shown is the organic-inorganic hybrid perovskite.

[0057] Figure 8 It is the dielectric diagram of the perovskite material described in this embodiment. It can be seen from the figure that t...

Embodiment 3

[0063] This example discloses an implementation of an organic-inorganic perovskite, specifically shown in the following reaction formula:

[0064]

[0065] The specific operation is to dissolve 1.107 g of lead bromide solid in 5 mL of methanol at room temperature, stir, and dropwise add hydrobromic acid with a mass fraction of 47% with a dropper to obtain a yellow clear solution I;

[0066] Dissolve 0.246 g of 3-hydroxypyrrolidine in 5 mL of methanol at room temperature to obtain a colorless and clear solution II;

[0067] Add the solution II to the solution I, continue to stir and react for half an hour, filter, put the obtained solution in an oven at 60°C for 36 hours, and finally obtain massive crystals, which are organic-inorganic hybrid perovskites as described in formula 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com