Preparation method of large-scale energy-storage low-cost neutral flow battery

A liquid flow battery, a low-cost technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of high corrosion, high cost, and inability to commercialize, and achieve raw material reserves, low cost, and low equipment prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the preparation method of the low-cost neutral flow battery for large-scale energy storage is as follows:

[0037] (1) Use deionized water to prepare 0.8mol L -1 ~3mol L -1 KOH or NaOH alkali solution;

[0038] (2) Put ion exchange membrane (such as: Nafion membrane, SPEEK membrane or SPES membrane) in 2mol L -1 In sulfuric acid, keep the temperature at 40°C to 90°C for 1 to 5 hours, its function is to completely convert the ion exchange membrane into the proton type, so as to facilitate the subsequent ionization treatment. Then, in deionized water at a temperature of 40° C. to 90° C. for 0.5 to 2 hours, the function is to wash away excess acid.

[0039] (3) Immerse the ion-exchange membrane obtained in step (2) in the alkali solution prepared in step (1), and keep the temperature at 50°C to 90°C for 1-4h, and its function is to completely convert the ion-exchange membrane into desired ionic type.

[0040] (4) Immerse the ion-exchange membrane obta...

Embodiment 2

[0050] The difference from Example 1 is that the preparation method of the low-cost neutral flow battery for large-scale energy storage is as follows:

[0051] (1) Dissolve ferricyanide (such as: potassium ferricyanide or potassium ferrocyanide) in a molar concentration of 1mol L -1 In aqueous potassium chloride solution, the molar concentration of ferricyanide is prepared to be 0.1mol L -1 positive electrolyte.

[0052] (2) the sulfide (K 2 S) Soluble in molar concentration 2mol L -1 In the aqueous potassium chloride solution, the molar concentration of the prepared sulfide is 0.3mol L -1 negative electrode electrolyte.

[0053] (3) Both positive and negative electrode materials are carbon felt.

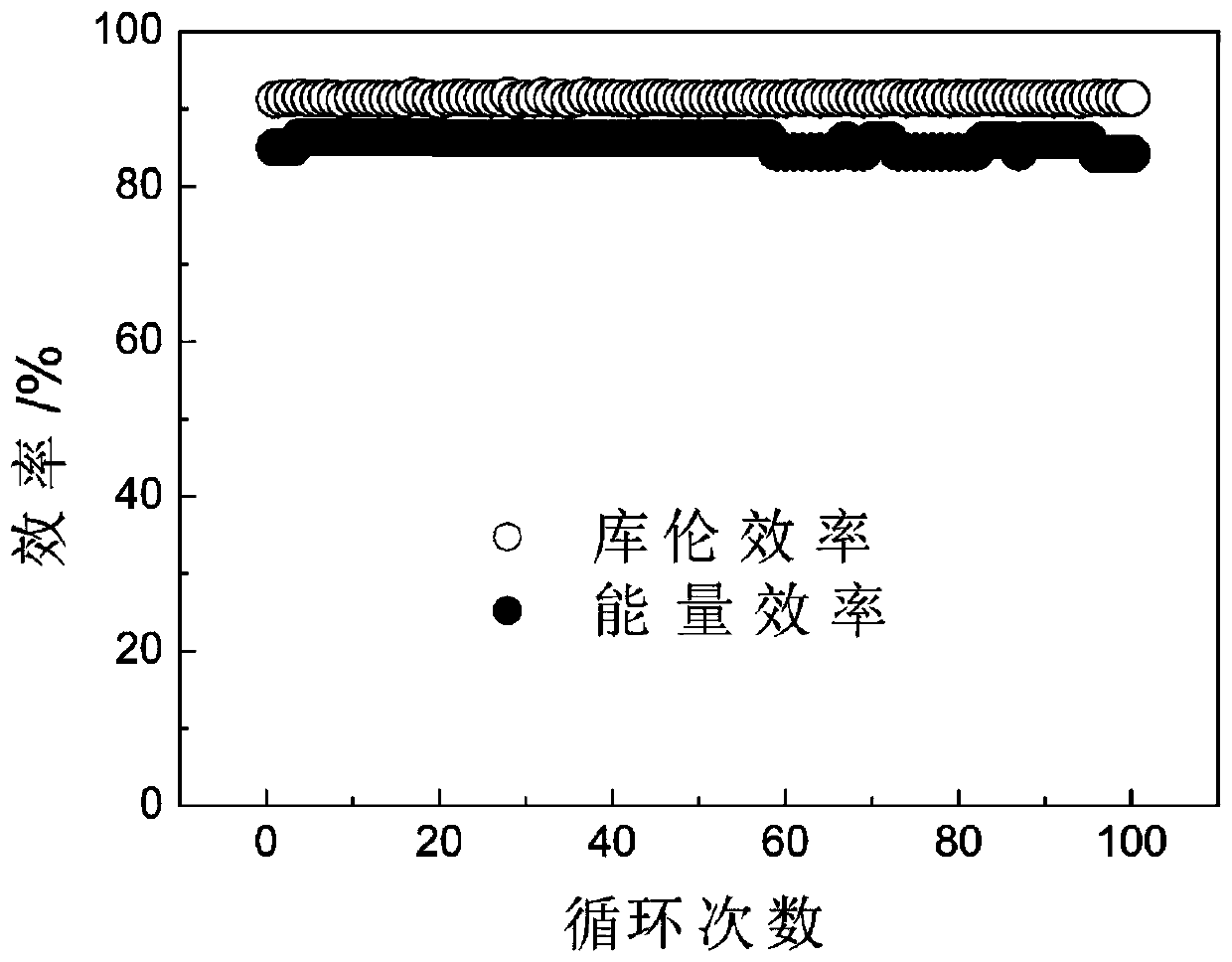

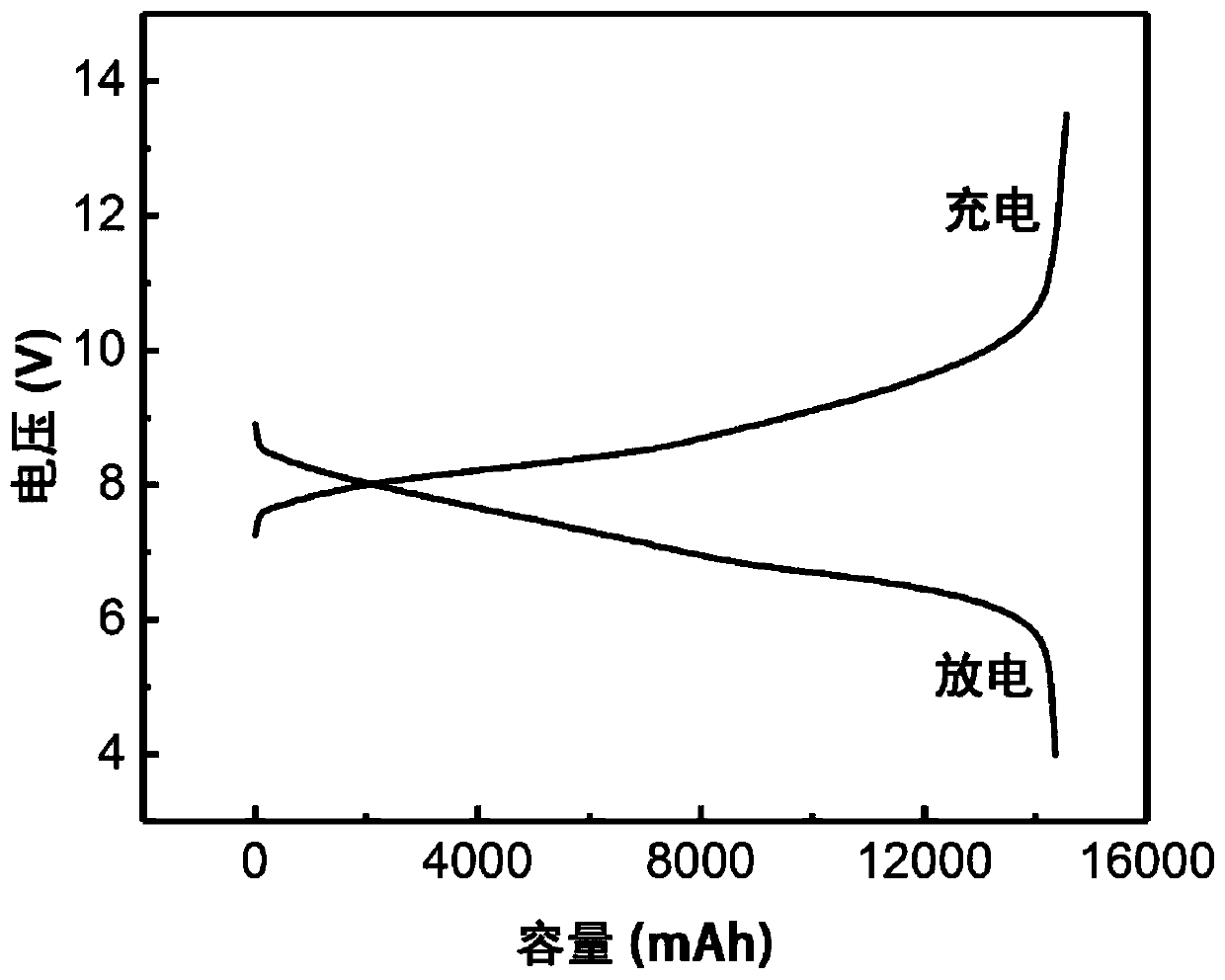

[0054] (4) Use potassium-ionized Nafion membrane or SPEEK membrane as a diaphragm, and use the above-mentioned positive and negative electrolytes and electrode materials to assemble a neutral flow battery single cell. The neutral zinc-iron flow battery has the advantages of lo...

Embodiment 3

[0058] The difference from Example 1 is that the preparation method of the low-cost neutral flow battery for large-scale energy storage is as follows:

[0059] (1) Dissolve ferricyanide (such as: sodium ferricyanide or sodium ferrocyanide) in a molar concentration of 1.5mol L -1 In aqueous potassium chloride solution, the molar concentration of ferricyanide is prepared to be 0.5mol L -1 positive electrolyte.

[0060] (2) the sulfide (such as: Na 2 S, Na 2 S 2 or Na 2 S 4 One or two mixtures) dissolved in a molar concentration of 2molL -1 In the aqueous potassium chloride solution, the molar concentration of the prepared sulfide is 2mol L -1 Negative electrolyte.

[0061] (3) Both positive and negative electrode materials are graphite felt.

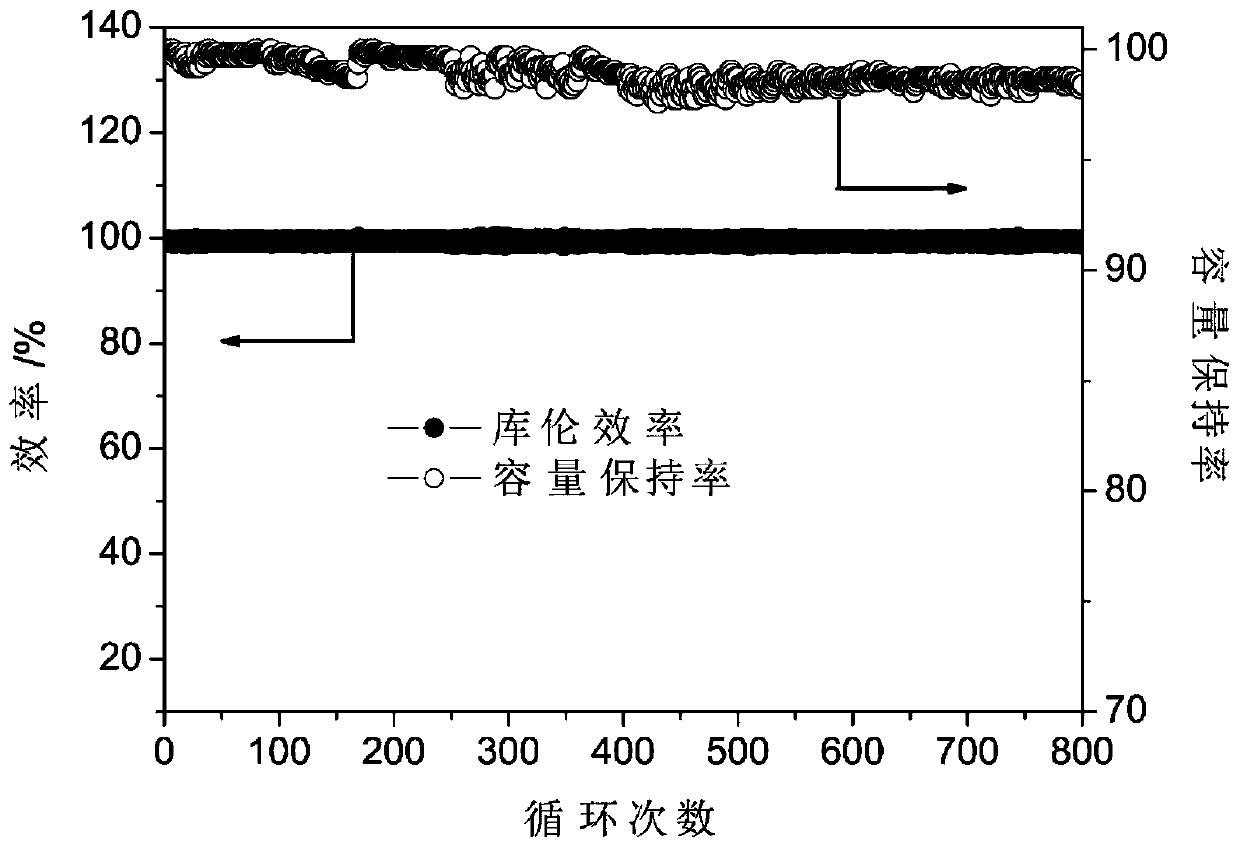

[0062] (4) Using sodium-ionized Nafion membrane or SPEEK membrane as a diaphragm, using the above positive and negative electrolytes and electrode materials to assemble 10 neutral flow battery stacks in series. The neutral zinc-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com