Method for preparing magnesium alloy part by utilizing 3D printing

A 3D printing and magnesium alloy technology, applied in the field of alloy forming and manufacturing, can solve the problems of magnesium alloy density, low melting and boiling point, flying magnesium alloy dust, affecting final performance, etc., to improve tensile plasticity and yield strength performance, quenching time The effect of optimizing and eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

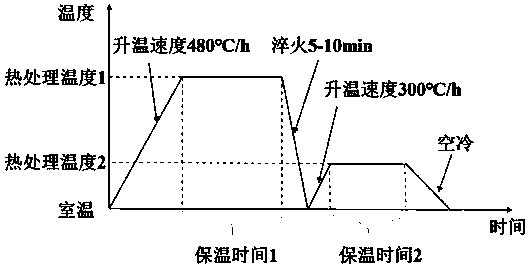

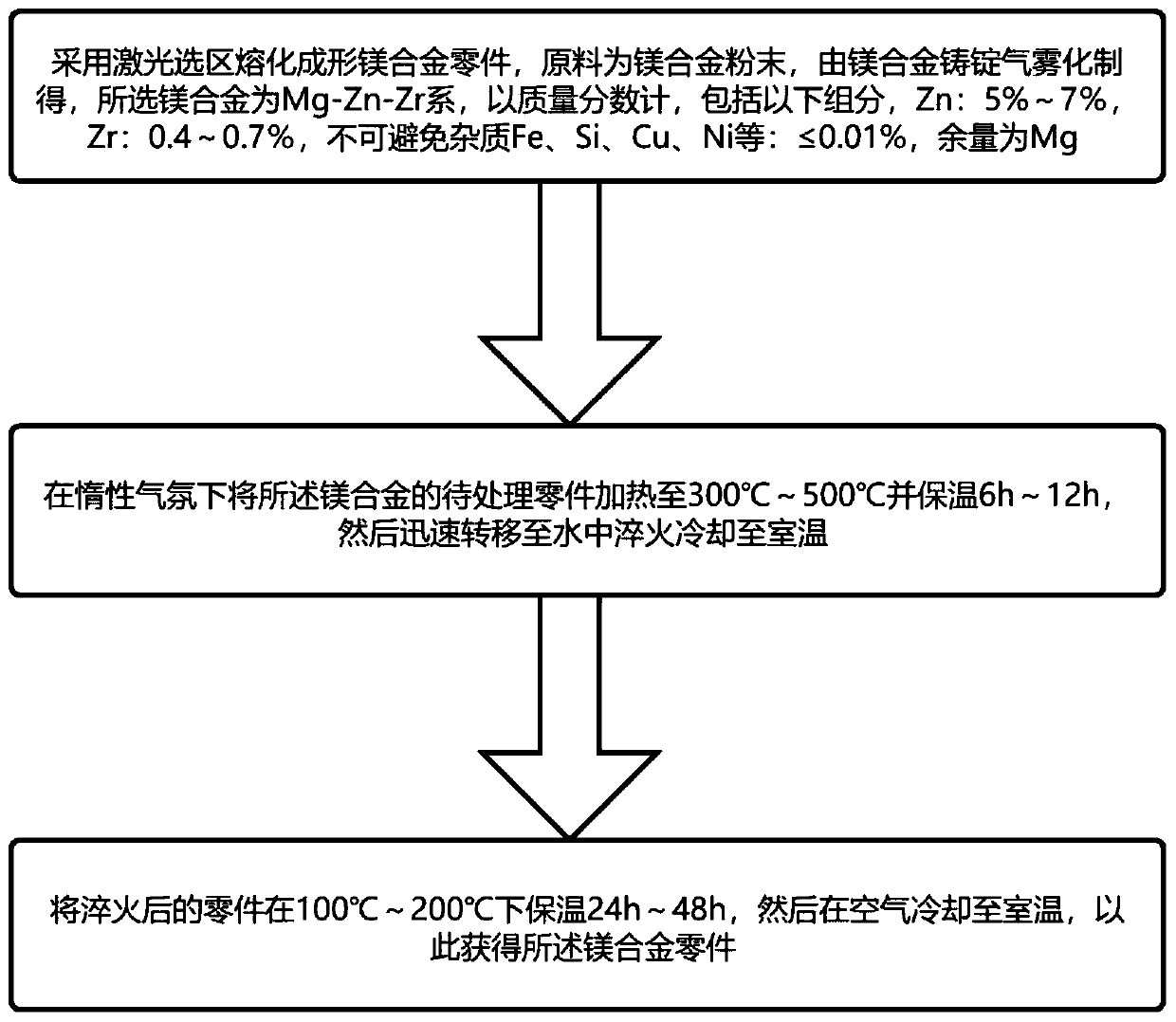

[0033] (a) using a selective laser melting process to prepare magnesium alloy parts to be processed, which includes the following components, Zn: 5%, Zr: 0.4%, impurities: 0.007%, and the balance is Mg;

[0034] (b) Put the magnesium alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 300°C at a rate of 480°C / h under a pure argon atmosphere and keep it warm for 12 hours, and then transfer it to water within 10s~20s Quenching for 5 minutes;

[0035] (c) keeping the quenched parts at 100° C. for 48 hours, and then cooling to room temperature to obtain magnesium alloy parts.

Embodiment 2

[0037] (a) using a selective laser melting process to prepare magnesium alloy parts to be processed, which includes the following components, Zn: 5%, Zr: 0.4%, impurities: 0.007%, and the balance is Mg;

[0038] (b) Put the magnesium alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 400°C at a heating rate of 480°C / h under a pure argon atmosphere and keep it for 9 hours, and then transfer it to water within 10s~20s Quenching for 5 minutes;

[0039] (c) keeping the quenched parts at 100° C. for 48 hours, and then cooling to room temperature to obtain magnesium alloy parts.

Embodiment 3

[0041] (a) using a selective laser melting process to prepare magnesium alloy parts to be processed, which includes the following components, Zn: 5%, Zr: 0.4%, impurities: 0.007%, and the balance is Mg;

[0042] (b) Put the magnesium alloy in a high-temperature box-type furnace, raise the temperature of the high-temperature box-type furnace to 500°C at a rate of 480°C / h under a pure argon atmosphere and keep it warm for 6 hours, and then transfer it to water within 10s~20s Quenching for 5 minutes;

[0043] (c) keeping the quenched parts at 100° C. for 48 hours, and then cooling to room temperature to obtain magnesium alloy parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com