High-wear-resistance PP rope

A highly wear-resistant and modified technology, applied in the field of plastics, can solve the problems of reduced mechanical properties and flexibility of the plastic body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of modified polypropylene is:

[0024] S1, preparation of modifier

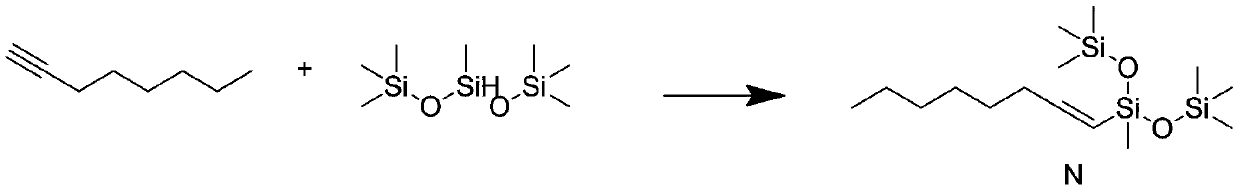

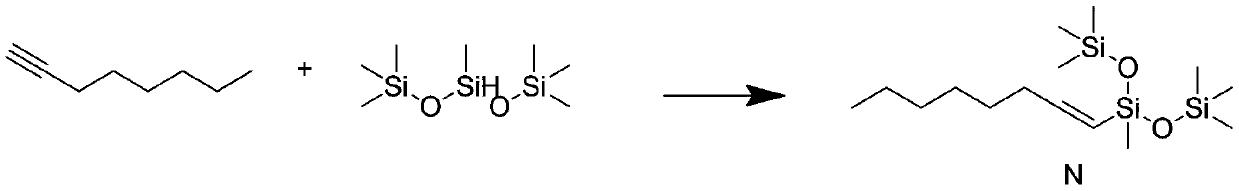

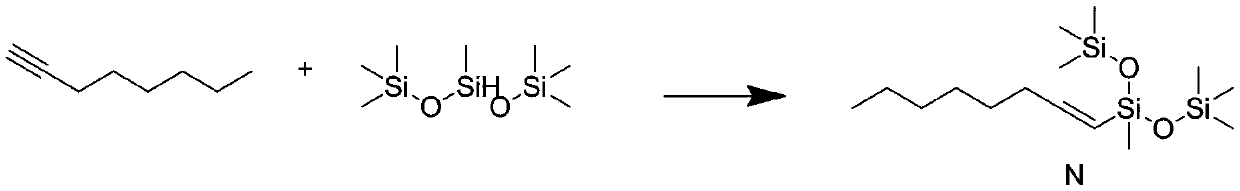

[0025] Add 1mol 1-octyne, 1.05mol bistrimethylsiloxymethylsilane, 3mmol catalyst chloroplatinic acid and 1L solvent isopropanol into the reaction kettle, feed nitrogen for 15min, replace the air in the reaction kettle, and Heat up to 80°C while stirring, keep warm and stir to react for 6 hours. After the reaction, remove the solvent by rotary evaporation, wash with anhydrous ether, and dry to obtain the modifier shown in formula N; the yield is 92.5%, and the reaction formula is as follows Shown:

[0026]

[0027] S2, preparation of modified polypropylene

[0028] Add 1 kg of deionized water, 1.5 g of emulsifier polyoxypropylene ether, 1.5 g of initiator sodium persulfate, and 77 g of propylene monomer into the reactor, transfer the reactor to a water bath, and perform prepolymerization at a temperature of 55 ° C React for 30 minutes, then remove the reaction kettle from th...

Embodiment 2

[0030] A high wear-resistant PP rope, including the following raw materials in parts by weight: 100g modified polypropylene, 15g filler, 8g EPDM rubber, 0.6g plasticizer, 0.4g antioxidant, 2g paraffin oil, 0.6g lubricant agent;

[0031] Described filler is calcium carbonate;

[0032] Described plasticizer is epoxy fatty acid methyl ester;

[0033] Said antioxidant is antioxidant 168;

Embodiment 3

[0036] A high wear-resistant PP rope, including the following raw materials in parts by weight: 120g modified polypropylene, 17g filler, 12g EPDM rubber, 1.2g plasticizer, 0.4g antioxidant, 3g paraffin oil, 1g lubricant ;

[0037] Described filler is calcium carbonate;

[0038] Described plasticizer is diethyl terephthalate;

[0039] Said antioxidant is antioxidant 168;

[0040] Described lubricant is zinc citrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com