Superfine three-dimensional platinum nanowire array growing on substrate under control of strong ligand, and method thereof

A technology of platinum nanowires and substrates, which can be used to grow ultra-fine three-dimensional platinum nanowire arrays on substrates and its fields under the control of strong ligands. Promote electrochemical activity and stability, large electrochemical active area, and improve the effect of electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for growing an ultrafine three-dimensional platinum nanowire array on a substrate under the control of a strong ligand, comprising the following steps:

[0039] (1) Surface amination treatment is carried out to the substrate, that is, the substrate is soaked in a mixed solution of APTES and acetic acid;

[0040](2) Take out the substrate in step (1), wash off the excess APTES solution, and then soak it in a solution of 3-5nm platinum particles;

[0041] (3) Take out the substrate in step (2), wash off the excess platinum seeds, and grow it in a mixed solution of 1.7mM chloroplatinic acid, 110μMMBIA, and 3.33mM sodium borohydride to obtain three-dimensional platinum nanowires array.

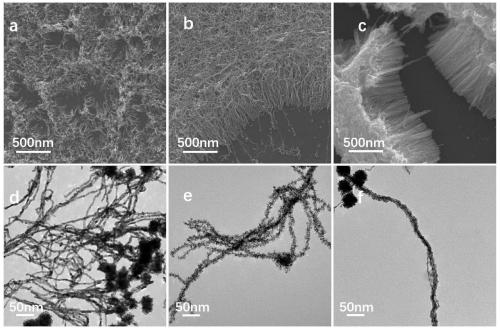

[0042] Figure 1 Figures b and e in this experiment are the SEM and TEM images of the platinum nanowire array obtained in this experiment. As can be seen from the figure above, the platinum nanowires obtained under this condition are all perpendicular to the substrate surface, w...

Embodiment 2

[0044] A method for growing an ultrafine three-dimensional platinum nanowire array on a substrate under the control of a strong ligand, comprising the following steps:

[0045] (1) Surface amination treatment is carried out to the substrate, that is, the substrate is soaked in a mixed solution of APTES and acetic acid;

[0046] (2) Take out the substrate in step (1), wash off the excess APTES solution, and then soak it in a solution of 3-5nm platinum particles;

[0047] (3) Take out the substrate in step (2), wash off the excess platinum seeds, and grow it in a mixed solution of 1.7mM chloroplatinic acid, 11μMMBIA, and 3.33mM sodium borohydride to obtain three-dimensional platinum nanowires array.

[0048] Figure 1 Figures a and d in this experiment are the SEM and TEM images of the platinum nanowire array obtained in this experiment. It can be seen from the figure above that the platinum nanowires obtained under this condition are all perpendicular to the surface of the s...

Embodiment 3

[0050] A method for growing an ultrafine three-dimensional platinum nanowire array on a substrate under the control of a strong ligand, comprising the following steps:

[0051] (1) Surface amination treatment is carried out to the substrate, that is, the substrate is soaked in a mixed solution of APTES and acetic acid;

[0052] (2) Take out the substrate in step (1), wash off the excess APTES solution, and then soak it in a solution of 3-5nm platinum particles;

[0053] (3) Take out the substrate in step (2), wash off the excess platinum seeds, and grow it in a mixed solution of 1.7mM chloroplatinic acid, 275μMMBIA, and 3.33mM sodium borohydride to obtain three-dimensional platinum nanowires array.

[0054] Figure 1 Figures c and f in this experiment are the SEM and TEM images of the platinum nanowire array obtained in this experiment. It can be seen from the above figure that the platinum nanowires obtained under this condition are all perpendicular to the substrate surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com