SO2-containing gas treatment method and device

A treatment method and gas technology, which is applied in the field of treatment of SO2-containing gas, and can solve problems such as inapplicability of adsorption materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

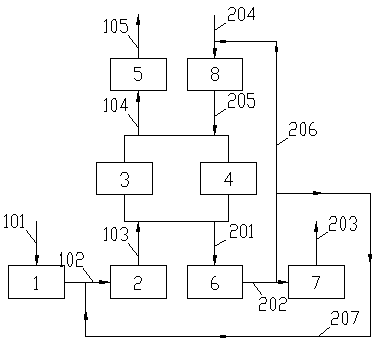

Method used

Image

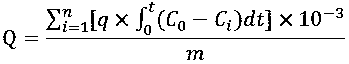

Examples

Embodiment 1

[0027] Contains SO 2 The gas is catalytic cracking regenerated flue gas, which is pretreated by dust removal, cooling, dehydration and drying before compression, and the SO in the exhaust gas after treatment 2 The volume concentration is 0.05% ~ 0.2% (about 285 ~ 5700mg / m 3 ), O 2 The volume concentration is 3% to 5%, and the flue gas treatment capacity is 1000Nm 3 / h.

[0028] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0029] will contain SO 2 The flue gas is compressed, the gauge pressure is controlled at 0.2-0.3MPaG, and then enters the adsorption unit for adsorption. The adsorption unit is filled with the above-mentioned modified zinc-based metal-...

Embodiment 2

[0032] Contains SO 2 The gas is flue gas regenerated by S-zorb adsorbent, which is pretreated by dust removal, cooling, dehydration and drying before compression, and SO in the exhaust gas after treatment 2 The volume concentration is 2% to 5%, O 2 The volume concentration is less than 0.2%, and the flue gas treatment capacity is 500Nm 3 / h.

[0033] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0034] will contain SO 2 The flue gas is compressed, the gauge pressure is controlled at 0.4-0.5MPaG, and then enters the adsorption unit for adsorption. The adsorption unit is filled with the above-mentioned modified zinc-based metal-organic framework material, a...

Embodiment 3

[0037] Contains SO 2 The gas is catalytic cracking regenerated flue gas, which is pretreated by dust removal, cooling, dehydration and drying before compression, and the SO in the exhaust gas after treatment 2 The volume concentration of O is 0.05% to 0.2%. 2 The volume concentration is 3% to 5%, and the flue gas treatment capacity is 1000Nm 3 / h.

[0038] Preparation of modified zinc-based metal-organic framework materials: using MOF-5 as the matrix, the specific surface area is 1655m 2 / g, the pore volume is 1.13cm 3 / g, Zn content 31.2%. The MOFs-5 were doped with 1.0% histidine by mass, and treated at 1000 °C for 6 hours in the presence of nitrogen to obtain modified Zn-based metal-organic framework materials.

[0039] will contain SO 2 The flue gas is compressed, the gauge pressure is controlled at 0.2-0.3MPaG, and then enters the adsorption unit for adsorption. The adsorption unit is filled with the above-mentioned modified zinc-based metal-organic framework mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com