Resource utilization method for synchronously treating Fenton iron sludge and obtaining FePO4

A synchronous processing and recycling technology, applied in the field of Fenton iron sludge recycling, can solve the problems of complex composition and hazardous waste of Fenton iron sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

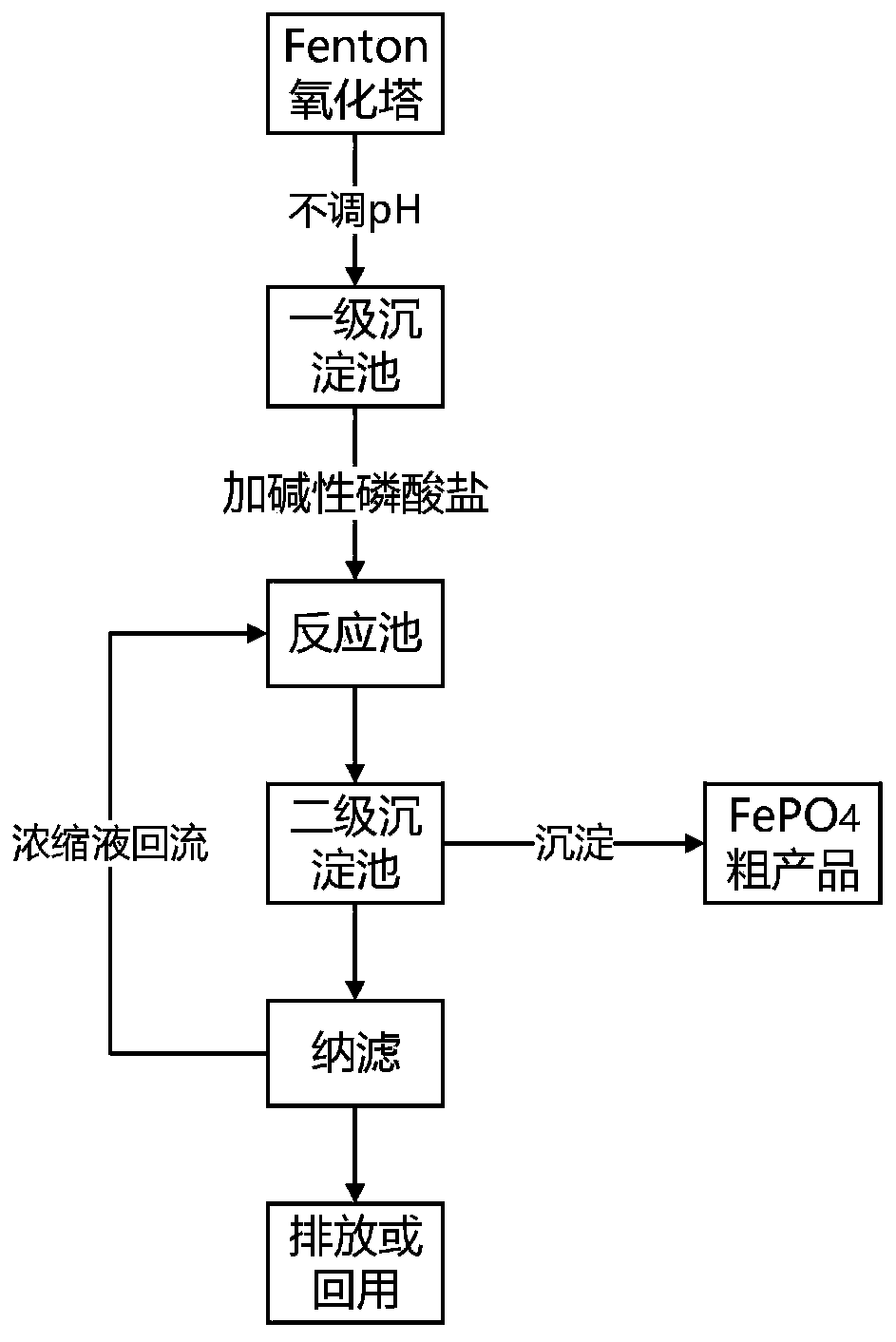

[0022] Taking a sewage treatment plant in an industrial park as an example, the sewage treatment plant in the industrial park adopts the Fenton process as an advanced treatment process, and uses the industrial sewage treatment plant to prepare FePO online 4 . The feed water flow rate of the Fenton reaction tower is 50m 3 / h, influent COD100mg / L, total phosphorus 2mg / L, the addition of hydrogen peroxide is 5kg / h, FeSO 4 The addition amount is 10kg / h. By adding dilute sulfuric acid online, the pH of the water entering the Fenton oxidation tower is 3.5. After the Fenton oxidation reaction, the COD of the Fenton reaction tower effluent is 60mg / L, Fe 3+ 75mg / L, total phosphorus 1mg / L, and then the effluent from the Fenton oxidation tower directly enters the primary sedimentation tank without adjusting the pH to remove suspended solids, organic matter and colloids in the Fenton effluent. The COD of the primary sedimentation tank effluent is 50mg / L, Fe 3+ 70mg / L, then enter the rea...

Embodiment 2

[0024] Taking a sewage treatment plant in an industrial park as an example, the sewage treatment plant in the industrial park adopts the Fenton process as an advanced treatment process, and uses the industrial sewage treatment plant to prepare FePO online 4 . The feed water flow rate of Fenton reaction tower is 100m 3 / h, influent COD200mg / L, total phosphorus 2mg / L, hydrogen peroxide addition 30kg / h, FeSO 4 The addition amount is 50kg / h. By adding dilute sulfuric acid online, the pH of the Fenton oxidation tower inlet water is 3.5. After the Fenton oxidation reaction, the Fenton reaction tower effluent COD is 80mg / L, Fe 3+ 150mg / L, total phosphorus 1mg / L, and then the effluent from the Fenton oxidation tower directly enters the primary sedimentation tank without adjusting the pH to remove suspended solids, organic matter and colloids in the Fenton effluent. The COD of the primary sedimentation tank effluent is 60mg / L, Fe 3+ is 350mg / L, then enters the reaction tank, and Na i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com